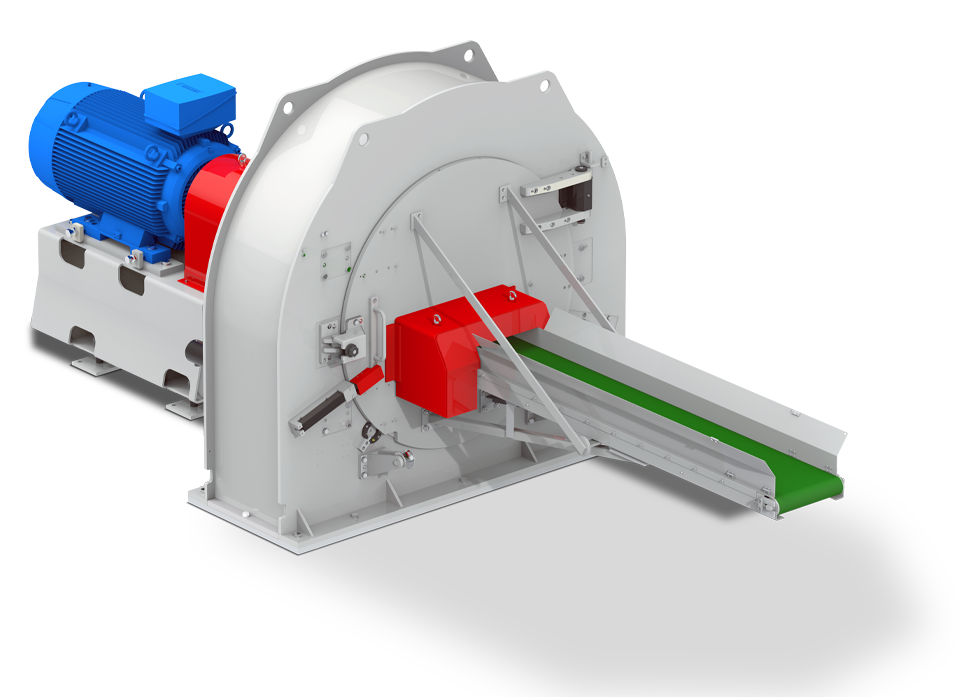

SRC – Knife Ring Flaker

Knife ring flaker with the lowest energy consumption and highest capacity on the market

Built with precision engineering and decades of experience in wood size reduction, SRC Knife ring flaker combines low energy consumption with high productivity and consistent flake quality.

Uniform flake size and precise cutting

Optimized edge cutting reduces glue consumption

Consistent wear part consumption

Wood based panels

PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets and black pellets

Applications and advantages of SRC knife ring flaker

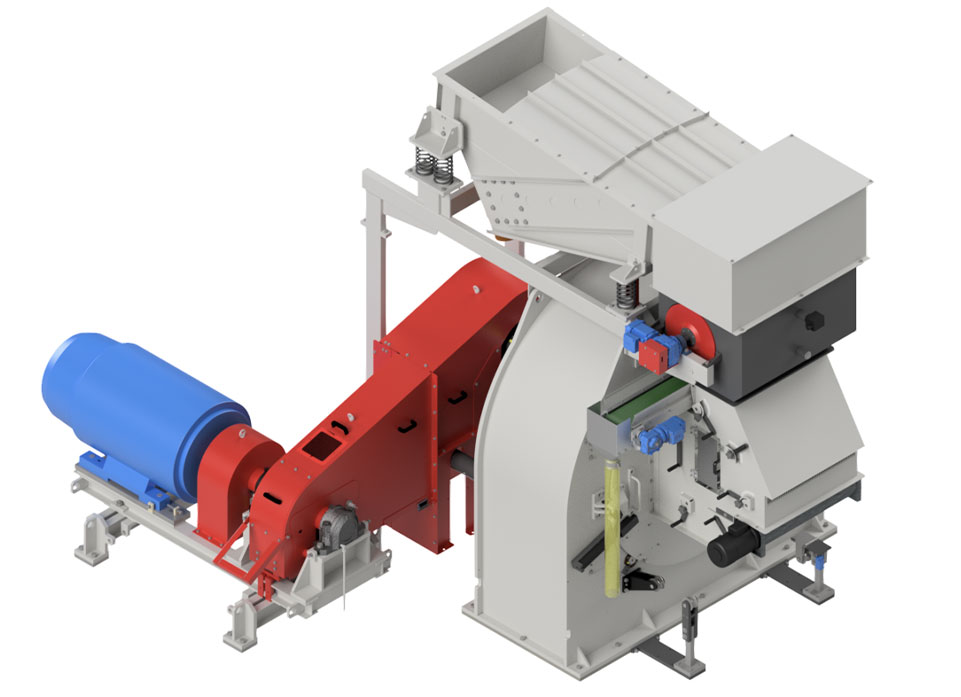

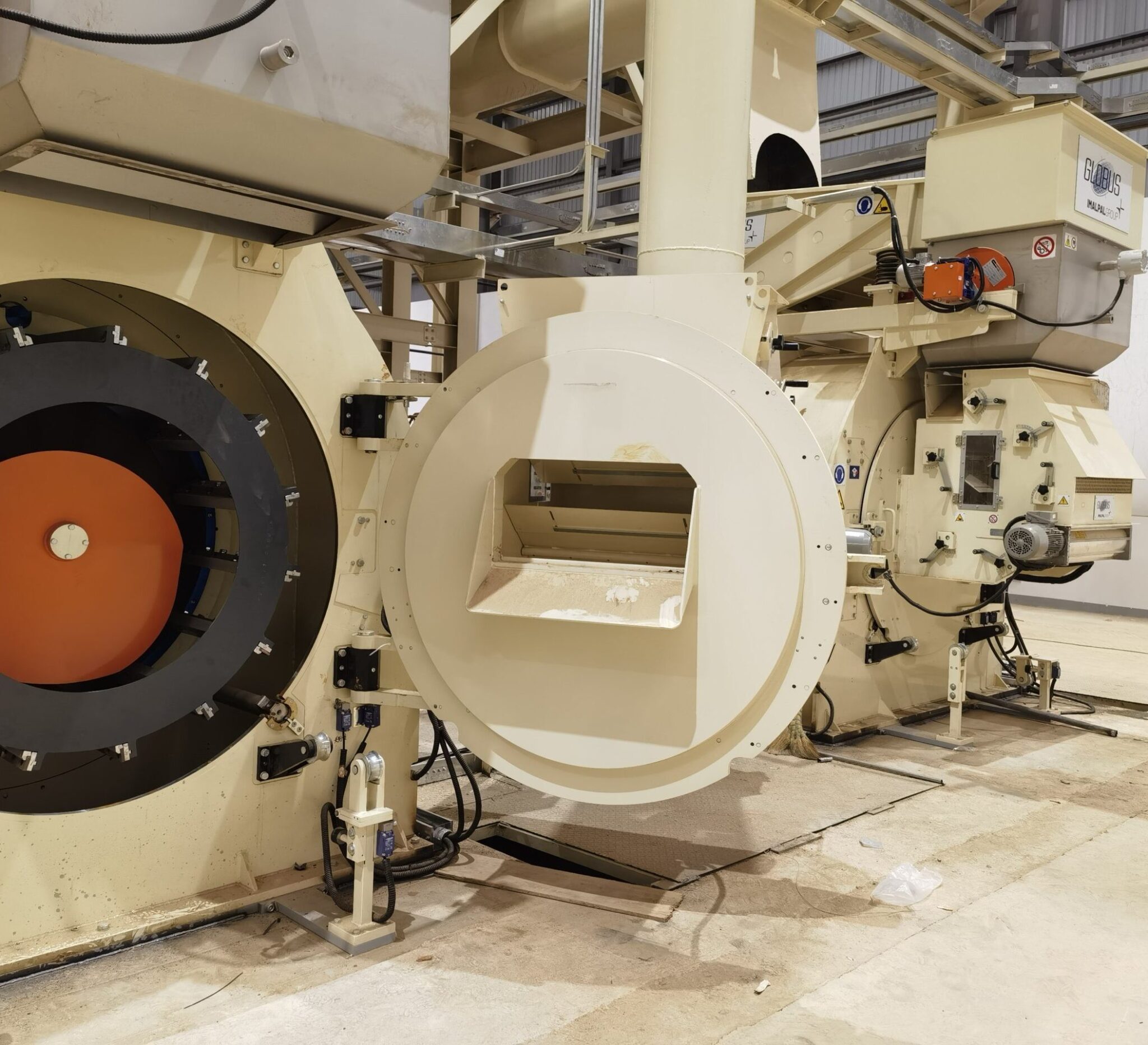

SRC knife ring flaker by Globus Srl is an advanced wood flaking machine designed for high-efficiency production of uniform flakes used in particleboard, MDF, OSB, and biomass plants.

Built with precision engineering and decades of experience in wood size reduction, the SRC flaker combines low energy consumption with high productivity and consistent flake quality.

In the wood-based panel industry, the quality of the flake directly affects board strength, surface smoothness, and resin distribution. The Globus knife ring flaker ensures a perfectly controlled cutting process, producing homogeneous flakes ideal for both surface and core layers.

| SRC 14.690 54-20 |

SRC 14.690 48-15 |

SRC 14.490 54-20 |

|

|---|---|---|---|

| CAPACITY | Up to 18 t/h b.d. | Up to 13 t/h b.d. | Up to 10 t/h b.d. |

| KNIFE RING DIAMETERS | 1400 mm | 1400 mm | 1400 mm |

| KNIVES | 54 | 48 | 54 |

| COUNTERKNIVES | 20 | 15 | 20 |

| KNIVES DIMENSION | 690 x 90 x 4 mm | 690 x 90 x 4 mm | 490 x 90 x 4 mm |

| RECOMMENDED MOTOR | 315 kW | 315 kW | 250 kW |

Increase production capacity

Improve material quality

Reduction of energy consumption

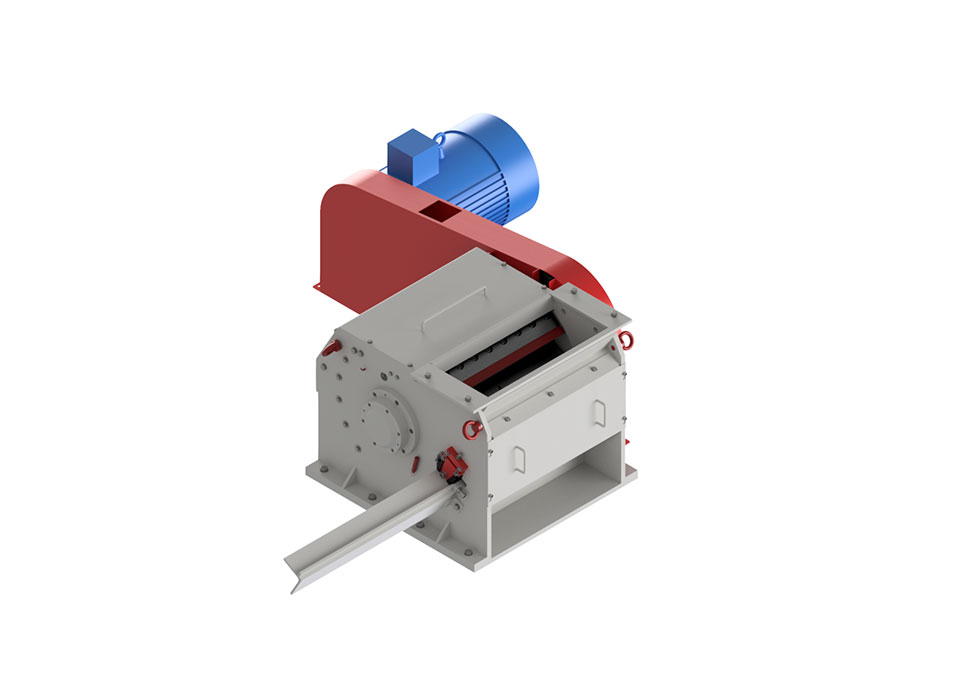

Technical features

Homogeneous flake granularity and precise wood cutting to enhance particleboard’s physical and mechanical properties

Optimized edge cutting reduces glue consumption

Very low specific energy consumption for cost-effective operation

Consistent wear part consumption, ensuring predictable maintenance costs

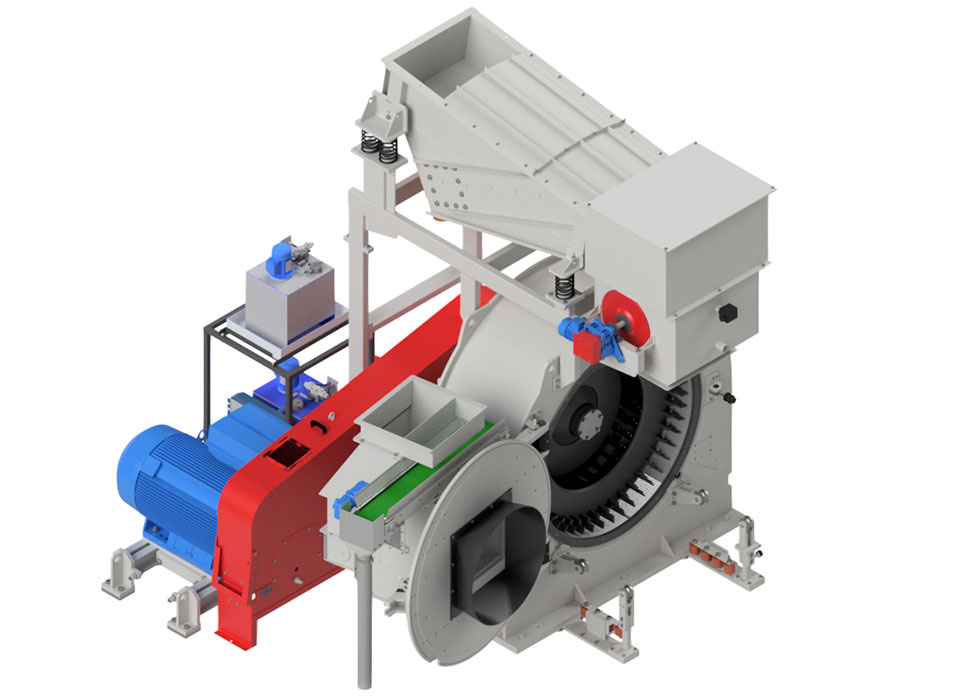

Innovative Wobble Disc Distribution System

Its innovative design, featuring a wobble disc distribution system, ensures optimal chip distribution across the entire length of the knife, maximizing cutting efficiency and flake uniformity.

This patented wobble spreader disc technology guarantees that wood chips are evenly distributed inside the machine, fully utilizing each knife’s cutting edge and reducing wear and energy consumption.

Key technical highlights include:

- Patented wobble spreader disc for uniform chip distribution inside the cutting chamber

- Independently driven eccentric disc to enhance precision and overall efficiency

- Optimized chip distribution for maximum knife edge utilization, lowering power demand and wear costs

- Extensive research to determine the ideal knife geometry and configuration (up to 54 knives)

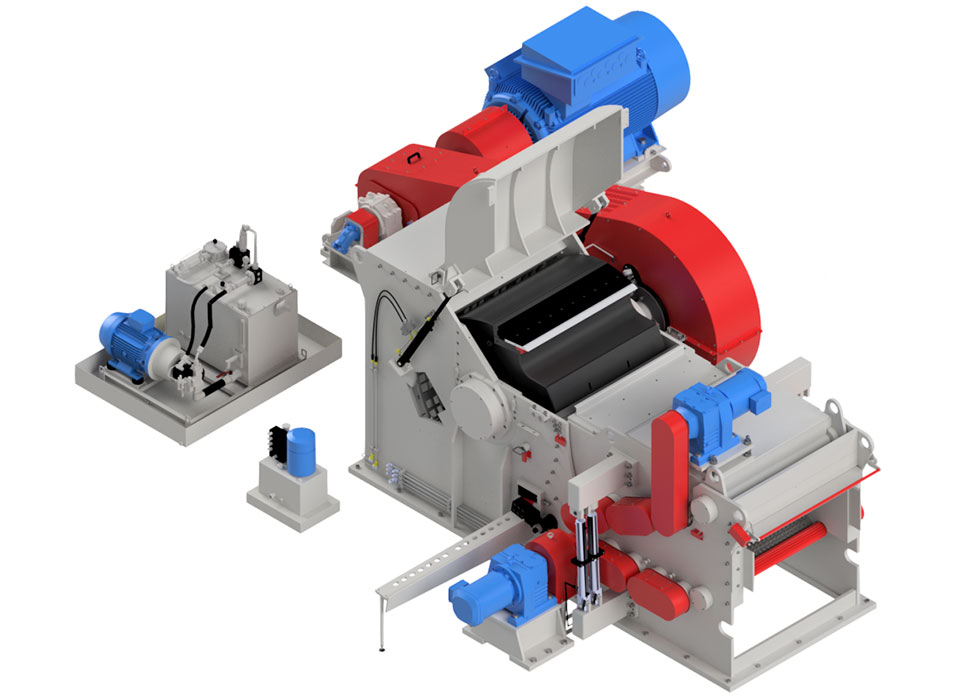

- Automated oil lubrication system for main bearings to minimize maintenance and downtime

- High-precision rotor with counterknife presetting system for accurate cutting geometry

- Feeding door with integrated air cleaner to remove heavy pollutants before flaking

These engineering solutions make the SRC knife ring flaker one of the most advanced and reliable systems for industrial wood flake production.

Efficiency, Reliability, and Integration

Thanks to its optimized knife ring design and aerodynamic material flow, the SRC flaker ensures high throughput with minimal energy use.

The robust structure and wear-resistant components guarantee long-term operation under continuous industrial load, while the user-friendly access doors simplify inspections and knife replacement.

Globus SRC knife ring flaker can be perfectly integrated with Globus drum chippers, vibrating conveyors, and screening systems to form a complete wood preparation line for particleboard or OSB production.

Optional SmartBox PLC controls allow continuous monitoring of vibration, temperature, and motor load.

Designed and manufactured in Italy, the SRC knife ring flaker represents the ideal combination of cutting precision, energy efficiency, and engineering innovation for the modern wood-processing industry.

The best way to improve high quality and capacity of flakes in particleboard production.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.