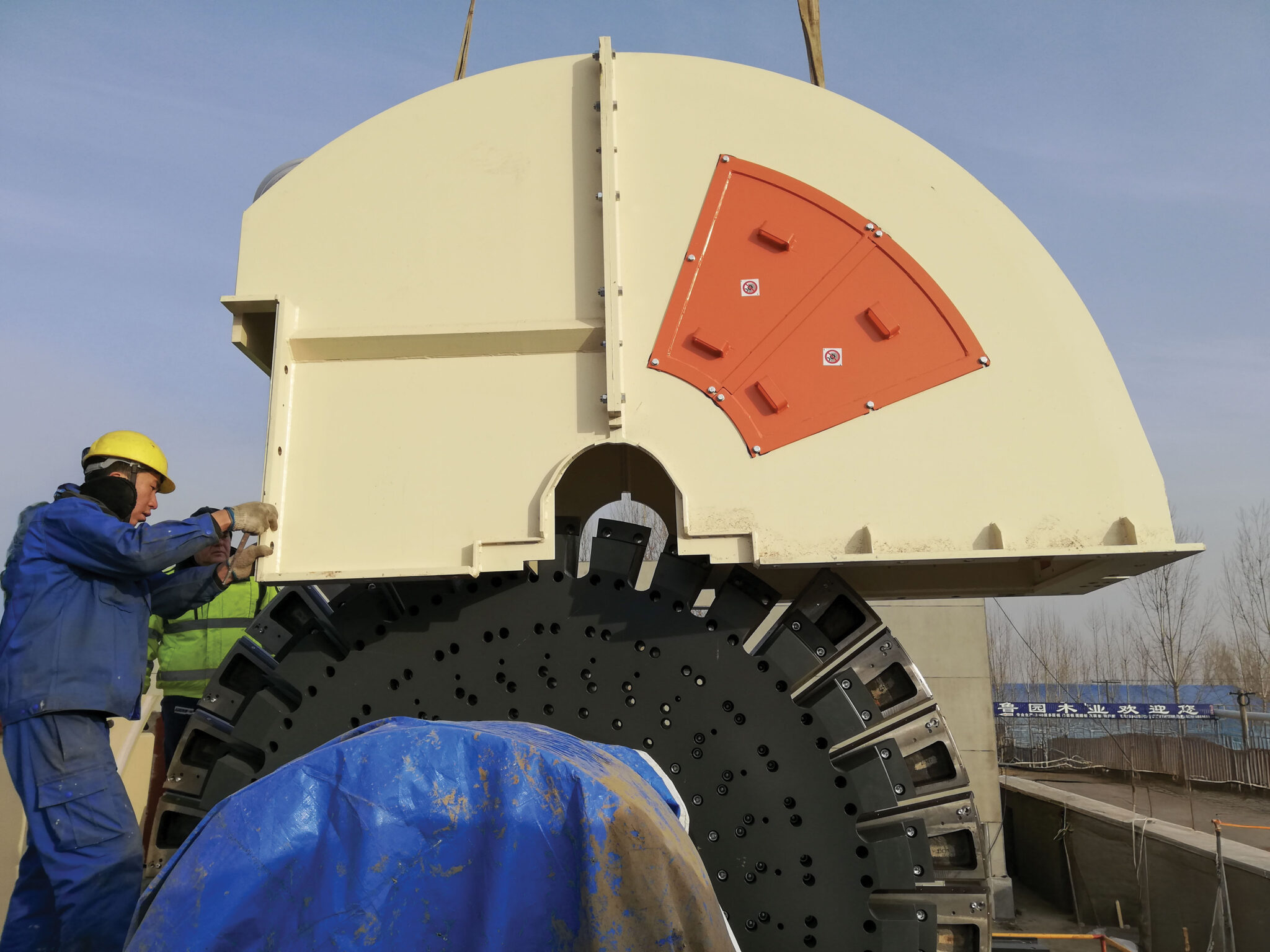

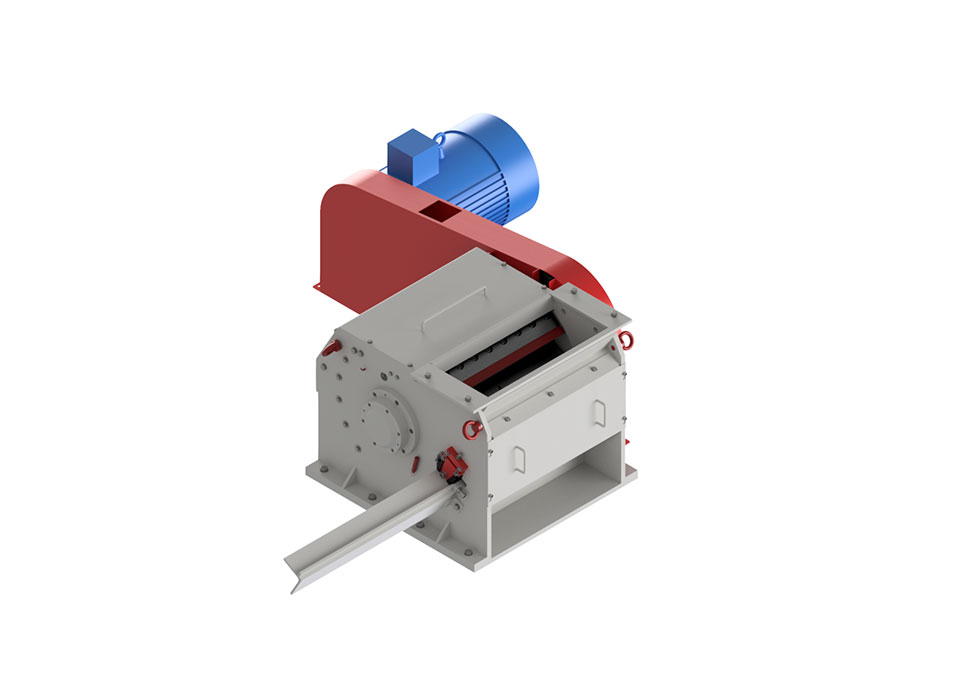

SDG – Strander Disc

Strander Disc processes batch-fed logs into high-quality strands and flakes for OSB panels

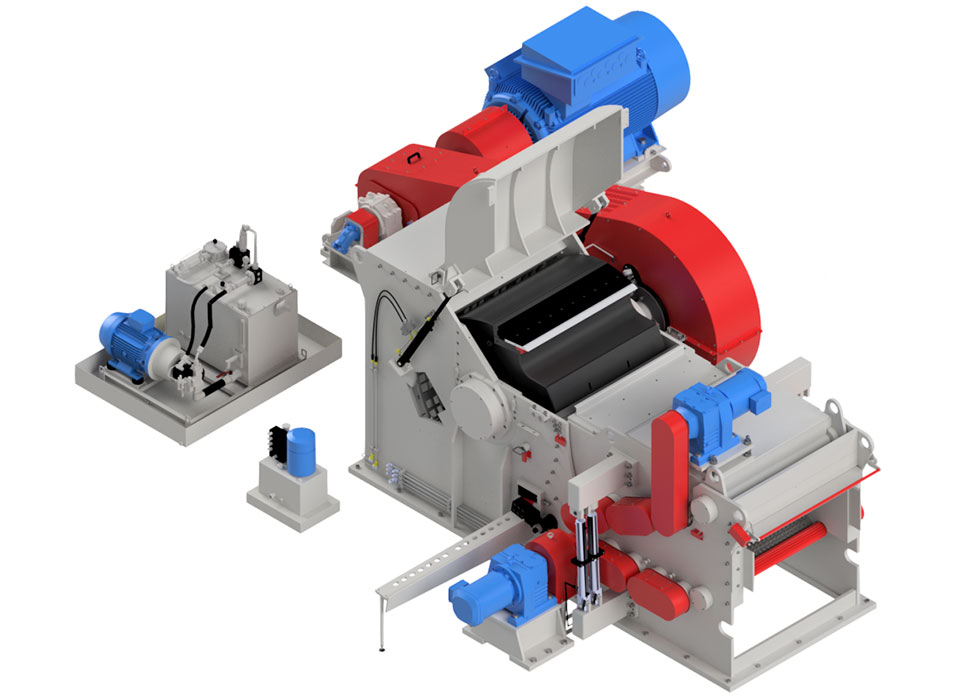

Different strander disc setups and configurations can be tailored based on the required strand particle size, ensuring flexibility, efficiency, and optimal performance in wood strand production.

Cutting disc long operating life

High dimensional strand control accuracy

Constant cutting with different logs sizes

Disposable knife or grinding knife version

Wood based panels

PB/SPB OSB/LSB/FOSB

Applications and advantages of SDG Strander Disc

SDG Strander Disc by Globus Srl is a powerful industrial machine designed for the production of wood strands used in OSB, LSB, and PB manufacturing.

Its robust disc design and high-precision cutting technology ensure consistent strand geometry, high capacity, and energy-efficient operation for modern wood-based panel plants.

This disc-type strander is engineered to process wood blocks, slabs, and residual materials into homogeneous strands, optimizing panel density, resin distribution, and final surface quality.

The SDG series represents the latest generation of industrial strander discs, combining cutting accuracy, long knife life, and minimal maintenance.

Customizable configurations for every production need

Advanced technology for consistent performance

Uniform strands for superior OSB

Technical features

High-precision cutting system for optimal strand quality

Fully automated and hydraulically assisted cutting process

Versatile design for OSB and low-density particleboard production

Long-lasting cutting disc for reduced maintenance needs

Advanced log handling for consistent and accurate output

Customizable knife options: disposable or resharpenable for maximum flexibility

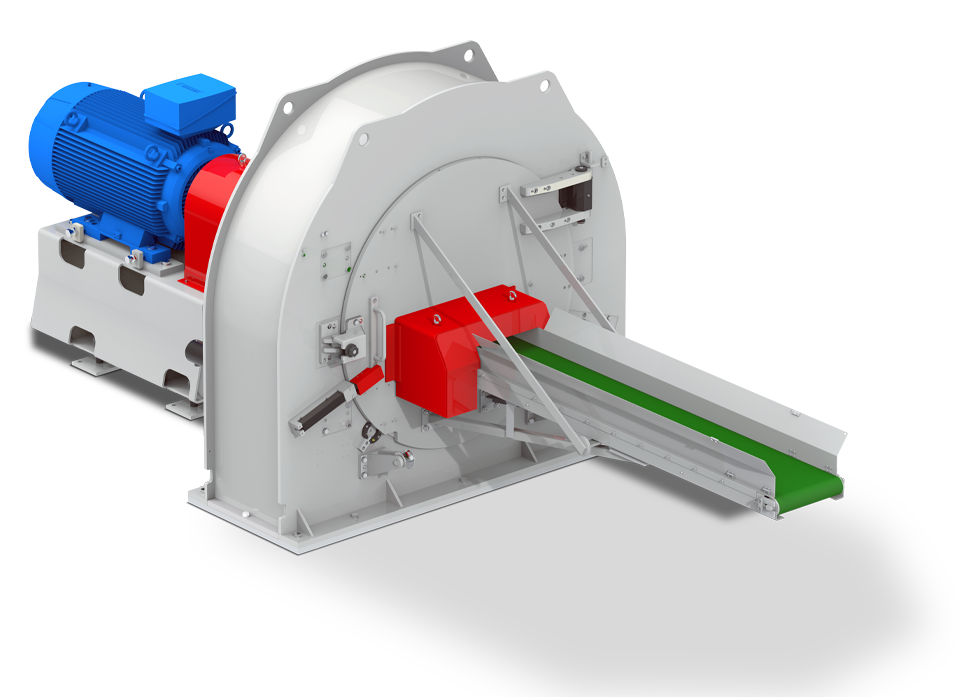

High-Precision Cutting Disc System

Equipped with a heavy-duty rotating disc and multiple knife configurations, the SDG strander disc guarantees superior cutting precision and a uniform strand profile.

Its advanced feeding and guiding system maintains optimal wood positioning, minimizing oversized particles and fines.

Different strander disc setups and configurations can be tailored based on the required strand particle size, ensuring flexibility, energy efficiency, and optimal performance in wood strand production.

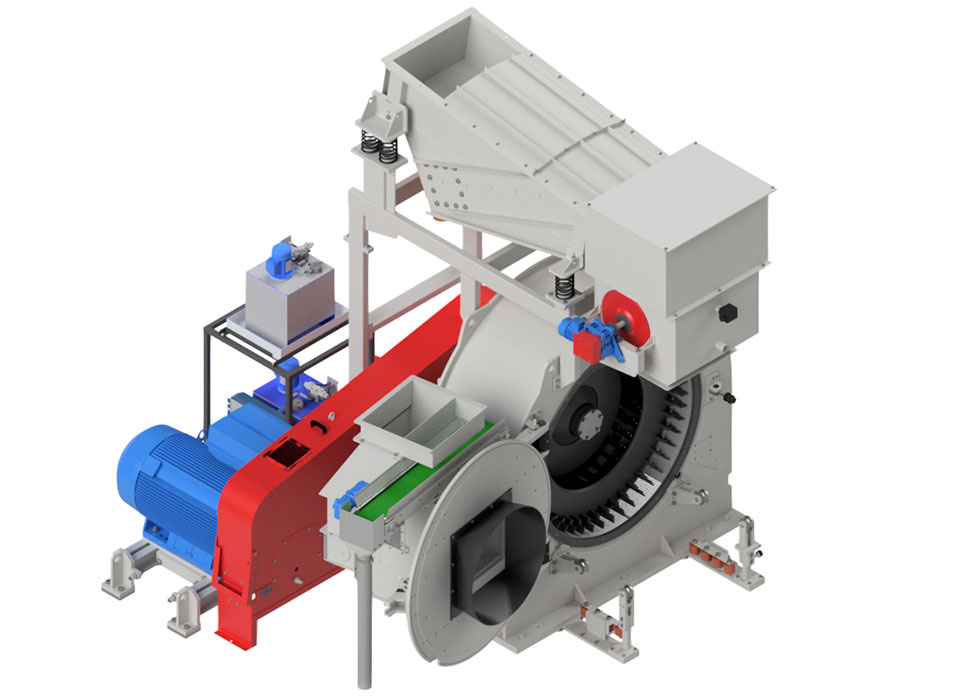

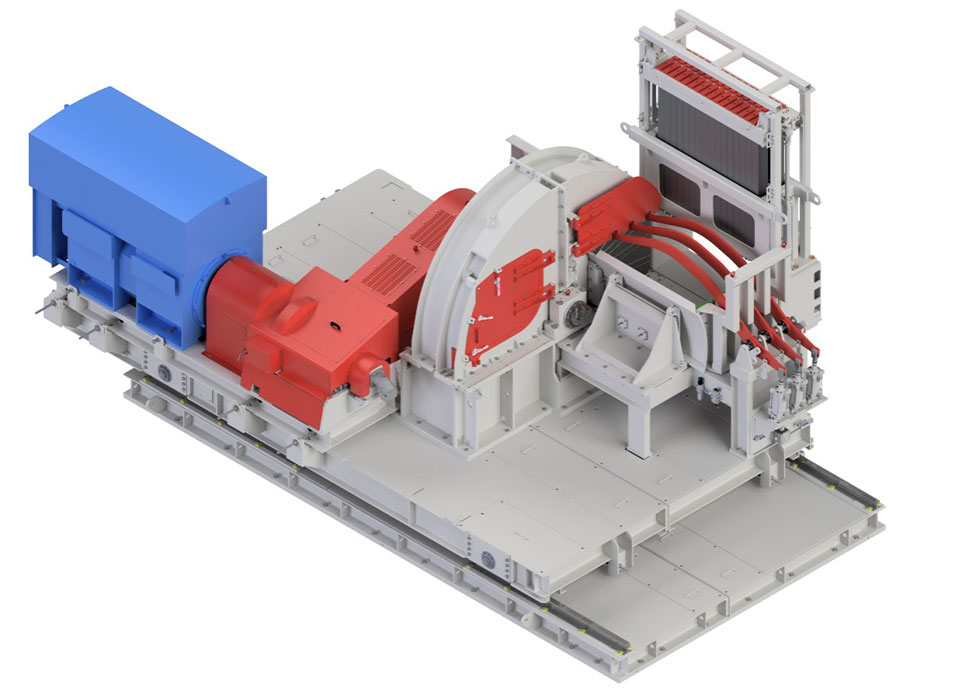

Efficiency and Reliability

The machine is designed with wear-resistant components, quick-access panels for knife replacement, and optional automatic lubrication for continuous operation.

These features make Globus SDG strander disc a reliable, low-maintenance solution for 24/7 industrial environments.

Integration in Complete Wood Preparation Lines

SDG Strander Disc integrates seamlessly with other Globus machinery such as the MTG Drum Chipper for pre-chipping and the SRC Knife Ring Flaker for fine flake production, forming a complete wood preparation line for OSB and particleboard plants.

Designed and manufactured in Italy, the Globus SDG Strander Disc combines precision, strength, and reliability — offering an energy-efficient, high-quality solution for the modern panel industry.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.