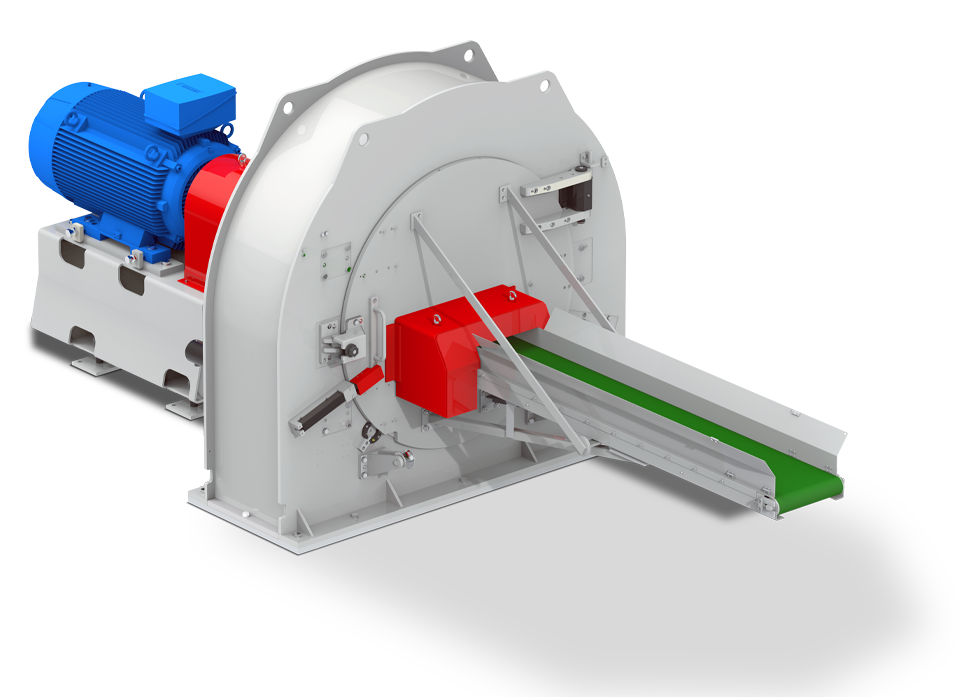

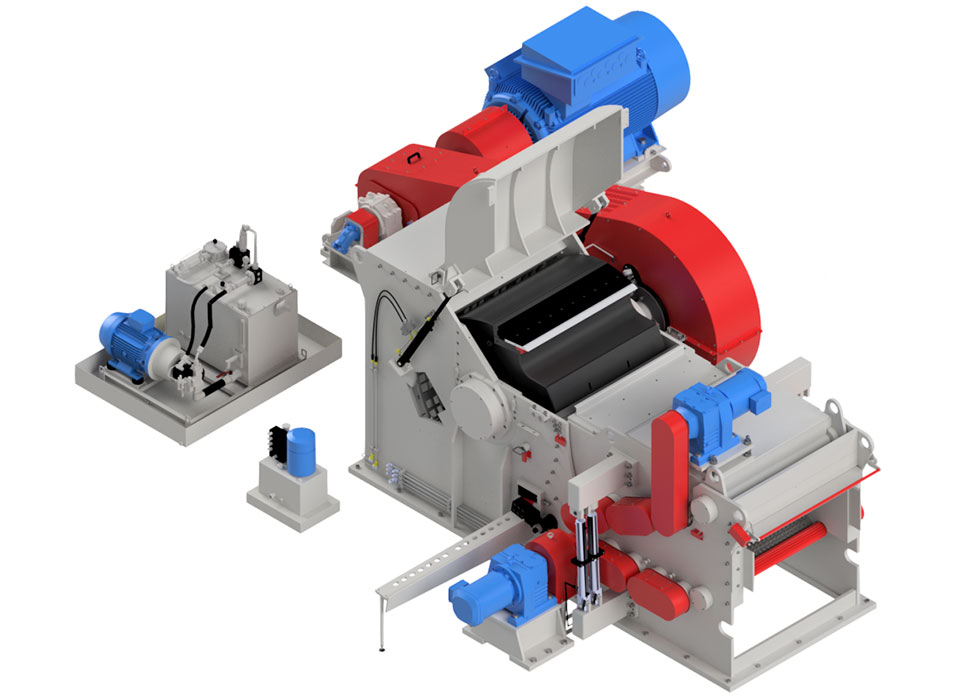

MTG – Drum Chipper

Industrial drum chipper for MDF, PB and low-density chip types

Drum chipper MTG provides the ability to create different machine setups for production of standard MDF/PB chips or MICROCHIPS, or SUPERCHIPS.

Easy digestion of all types and sizes of wood logs and materials

Minimized energy consumption

Low maintenance timing

Wood based panels

MDF/HDF PB/SPB

Pressed wood packaging

Pallet blocks & Pressed pallets

Pellets & energy

Green fuels and biomass, wood pellets and black pellets

Applications and advantages of MTG industrial Drum Chipper

In the wood processing industry, the quality and efficiency of material reduction are essential for optimizing production processes. MTG industrial drum chipper by Globus Srl is designed to deliver high-capacity, precise, and consistent chipping performance for all types of wood.

MTG drum chipper transforms logs, slabs, trimmings, and wood waste into high-quality chips suitable for MDF, particleboard, OSB panels, and biomass applications.

Thanks to its robust construction and advanced engineering, it guarantees reliable performance with minimal maintenance, reducing operational costs and maximizing productivity.

Built for efficiency and versatility, MTG machines handles a wide range of wood sizes and materials.

The optimized infeed system ensures high throughput and minimal waste, making it ideal for wood-based panel industries, biomass power plants, and recycling applications.

Constant quality of chips

Low energy consumption

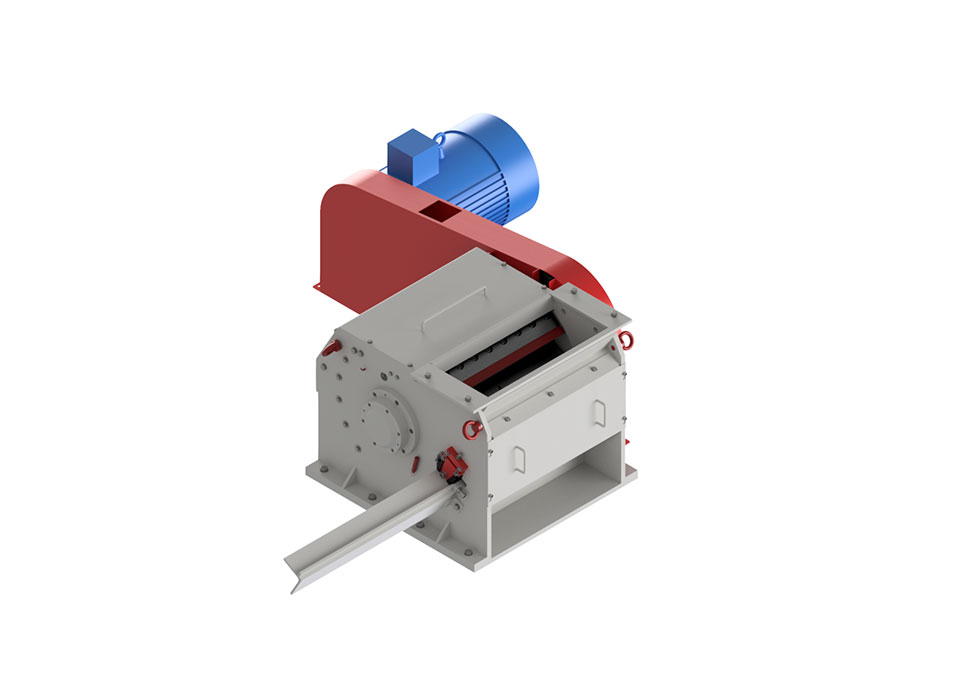

Easy change of knives and counter-knives

Technical features

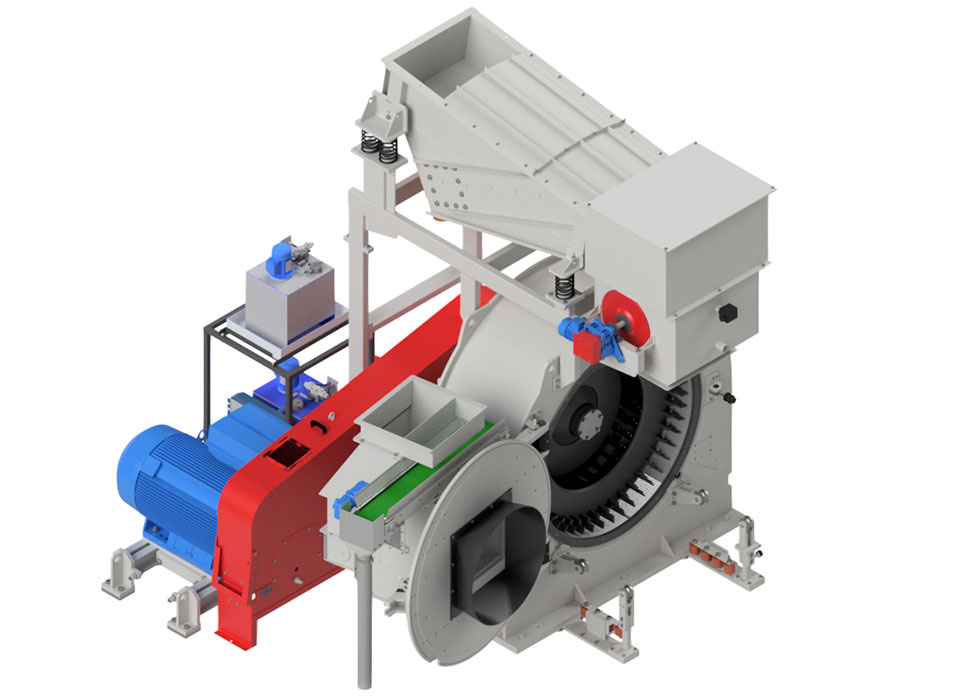

Two knife clamping systems: mechanical bolt system or centrifugal wedgeshaped system, adaptable to various applications

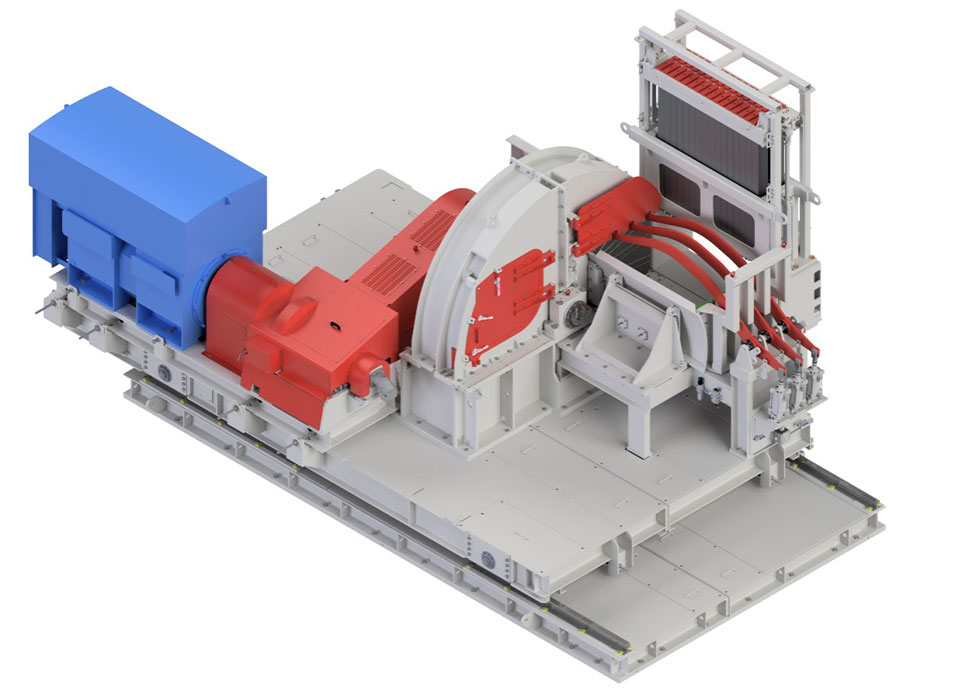

Rotor diameters ranging from 600 to 2400 mm, with 3 to 6 knives, for different processing needs

Different knive interchangeable screens, with a two-part screen design for quick replacement

Hardened steel feeding rollers with precision-cut edges for durability and efficiency

Robust drive system with double pinion/key block system and ring feeder, ensuring powerful transmission and easy maintenance

Hydraulic or soft-start acceleration unit for smooth operation

Hydraulic counterknife ejection system for easy maintenance

Side inspection door for quick and convenient screen checks

Optimal log alignment for precise cutting

Advanced feeding and positioning systems provide accurate log alignment, reducing oversized chips and improving chip homogeneity. This precision directly enhances the quality of the final product and ensures smoother downstream processing in flakers or refiners.

Quick knife and counterknife replacement

User-friendly mechanisms allow fast and safe knife changes, minimizing downtime.

Features such as automatic rotor positioning and hydraulic counterknife ejection further simplify maintenance and guarantee consistent cutting geometry throughout production.

Minimal maintenance for maximum uptime

MTG drum chippers are built with wear-resistant components and easy access to key parts. This results in reduced servicing time, simplified inspections, and continuous operation even under heavy-duty industrial use.

Designed and manufactured in Italy, Globus MTG industrial drum chipper combines high mechanical strength with energy-efficient performance.

Precision, durability, and innovation for superior wood chipping performance.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.