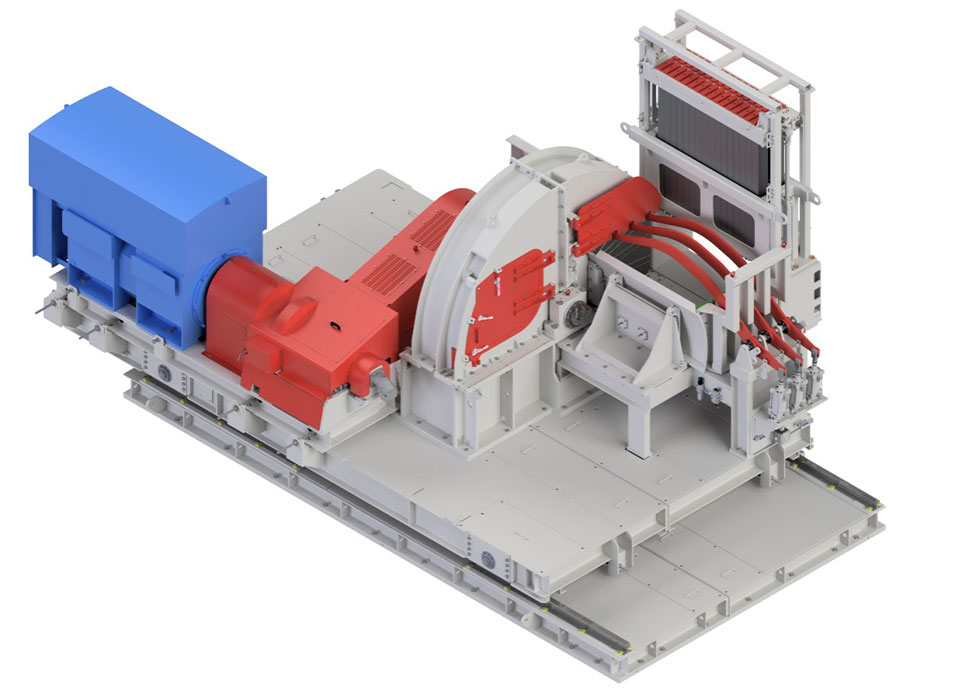

RMG – Rechipper

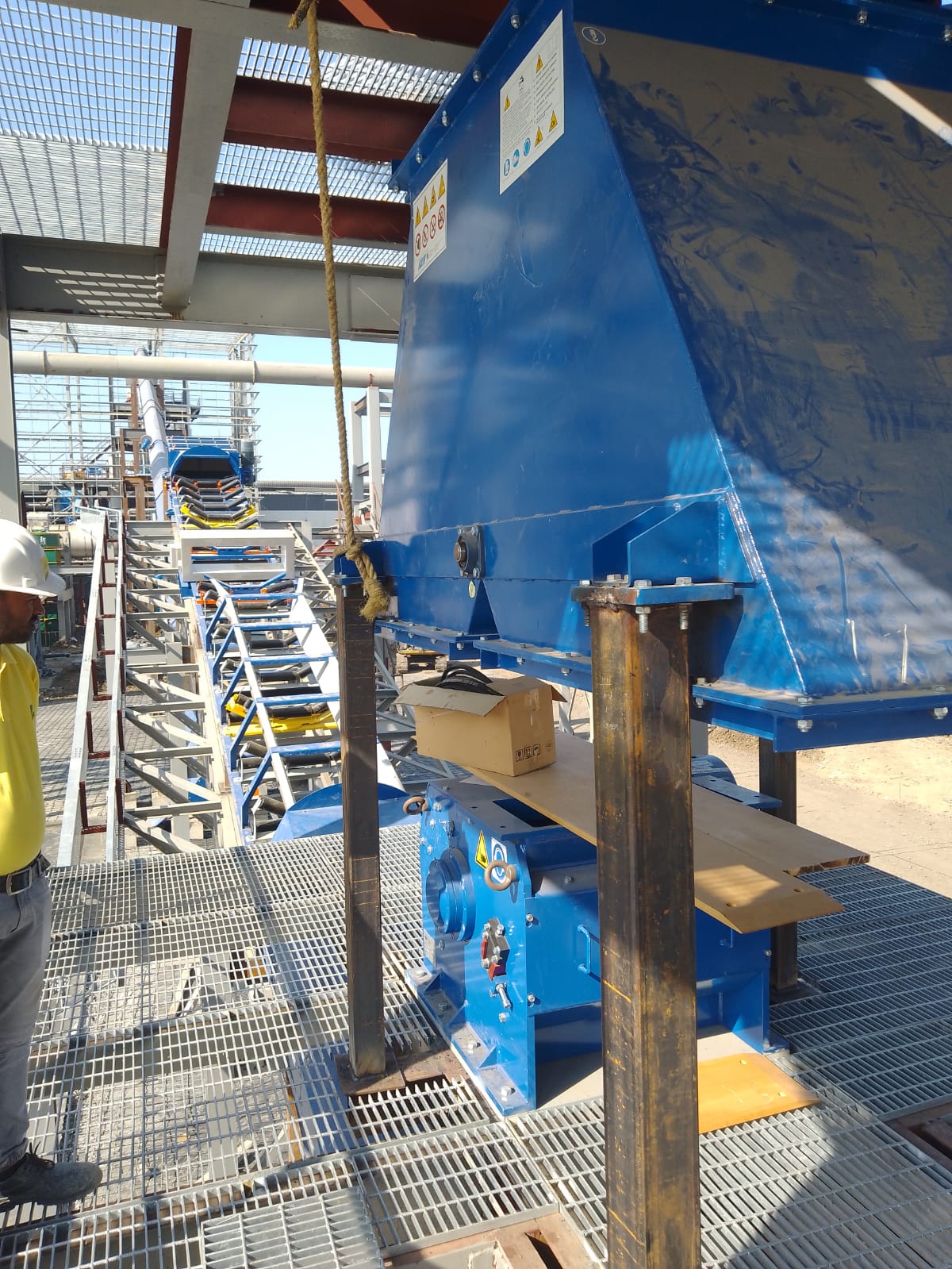

Versatile rechipper machine for efficient wood processing

RMG rechipper machine by Globus Srl effectively processes small wood residues, bark, forestry waste, and oversized materials from other size-reduction machines, delivering high-capacity, energy-efficient chip production for biomass and wood panel manufacturing.

Easy digestion of all types of wood materials

Easy change of knives

Lateral counter-knife ejection on sliding guide

Efficiency and low maintenance

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Green fuels and biomass, wood pellets and black pellets

Applications and advantages of RMG Rechipper Machine

RMG rechipper machine by Globus Srl is a high-performance unit designed to process oversized wood chips, slabs, and other wood residues into uniform chips suitable for OSB, particleboard, pressed wood packaging, and biomass applications.

Its rugged design and precise cutting system ensure consistent results, reduced waste, and optimal performance in continuous industrial operation.

This industrial rechipper is an essential component in complete wood preparation lines, guaranteeing uniform chip dimensions before flaking or refining stages.

It efficiently handles wood waste from sawmills, chipping lines, or recycling plants, transforming it into reusable, high-quality chips that can be directly used in subsequent production processes.

Efficient wood processing

Low maintenance for maximum uptime

Easy change of knives and counter-knives

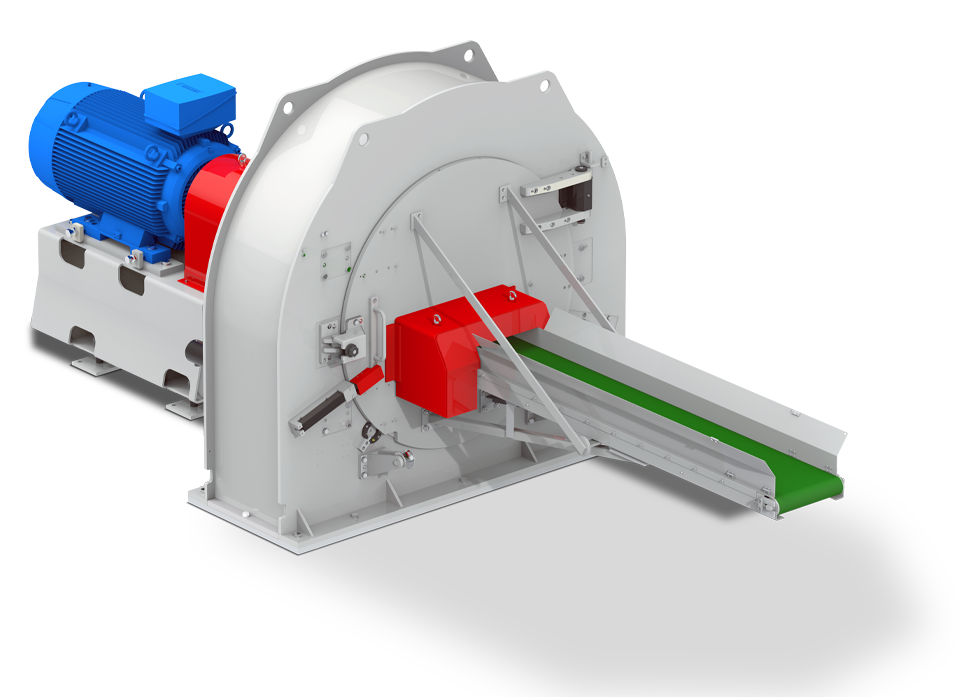

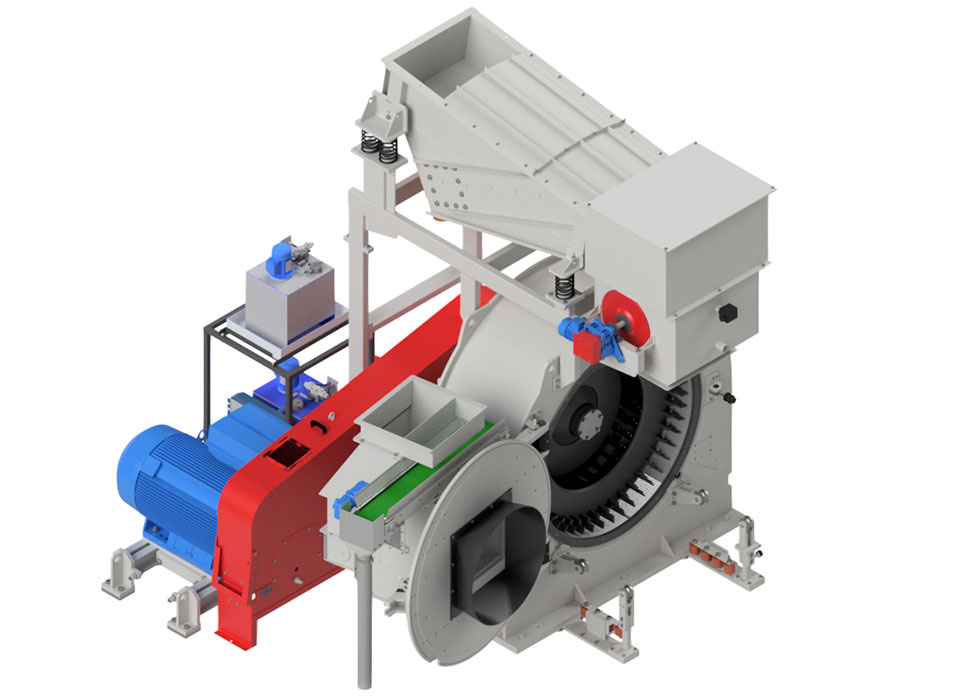

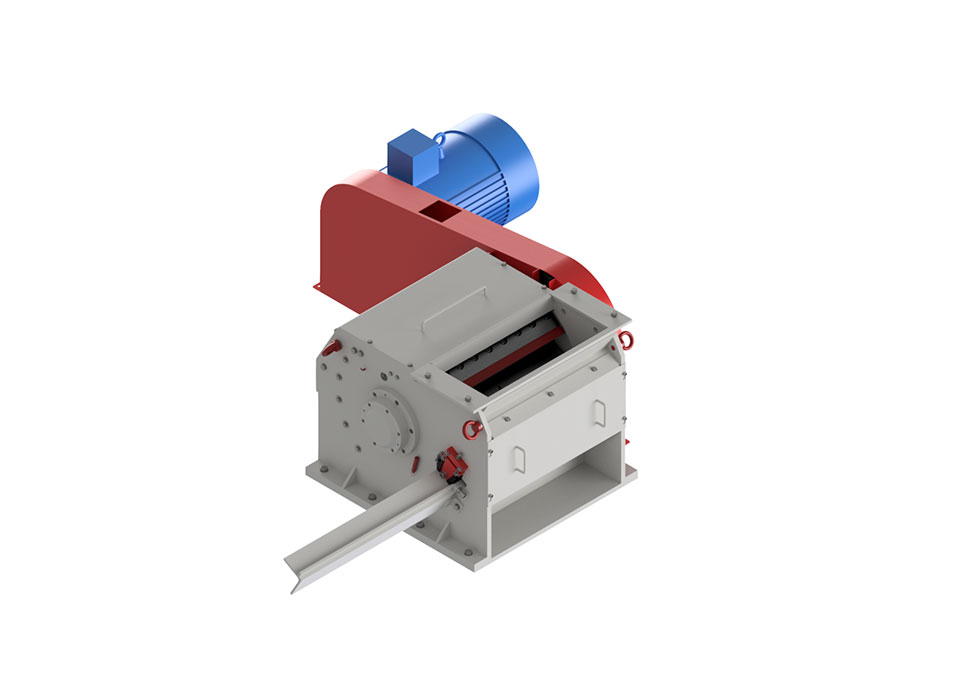

Technical features

Top-fed gravity system for an efficient and uniform processing

Able to process small rejected wood materials such as barks or forestry waste and also the wood over-size coming from others size of reduction machineries

Simple knife replacement, lateral ejection of the counter-knife on a sliding guide

Performance, Reliability, and Easy Maintenance

RMG rechipper machine offers several advantages, including easy digestion of all types of wood materials, simple knife replacement, lateral ejection of the counterknife on a sliding guide, minimized energy consumption, and low maintenance costs.

These features make it a reliable and cost-effective solution for high-capacity industrial operations.

Efficient Wood Processing – RMG handles various wood types and sizes, offering high throughput capacity and minimal waste, even with irregular material geometry.

Quick Knife and Counterknife Replacement – user-friendly mechanisms allow fast, safe blade changes, minimizing downtime and ensuring continuous production flow.

Low Maintenance – durable, wear-resistant components and easy access for inspections guarantee minimal servicing requirements and maximum uptime.

The combination of robust construction, precise cutting geometry, and simplified maintenance ensures consistent chip quality and long-term reliability, even under intensive use.

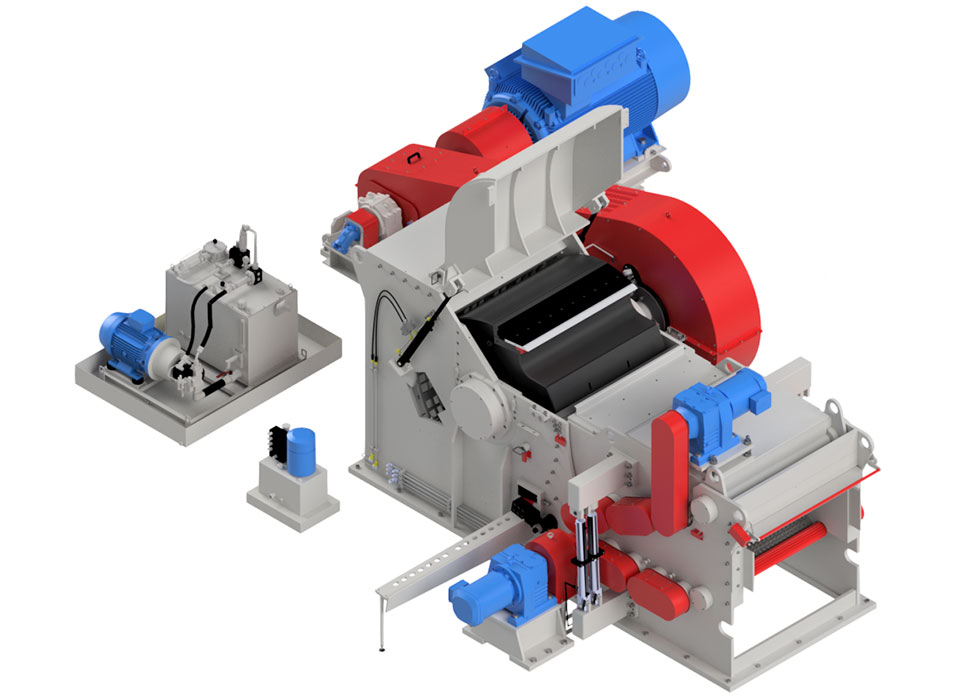

Integration in Complete Wood Preparation Lines

Globus RMG rechipper integrates perfectly with other Globus equipment, such as the MTG Drum Chipper for pre-chipping operations and the SRC Knife Ring Flaker for fine flake production.

Together, these systems form complete wood size reduction lines for panel, packaging, and biomass industries.

Designed and manufactured in Italy, the RMG rechipper machine represents precision, efficiency, and durability, delivering excellent chip quality and long-term reliability for any wood processing line.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.