RevoStrand

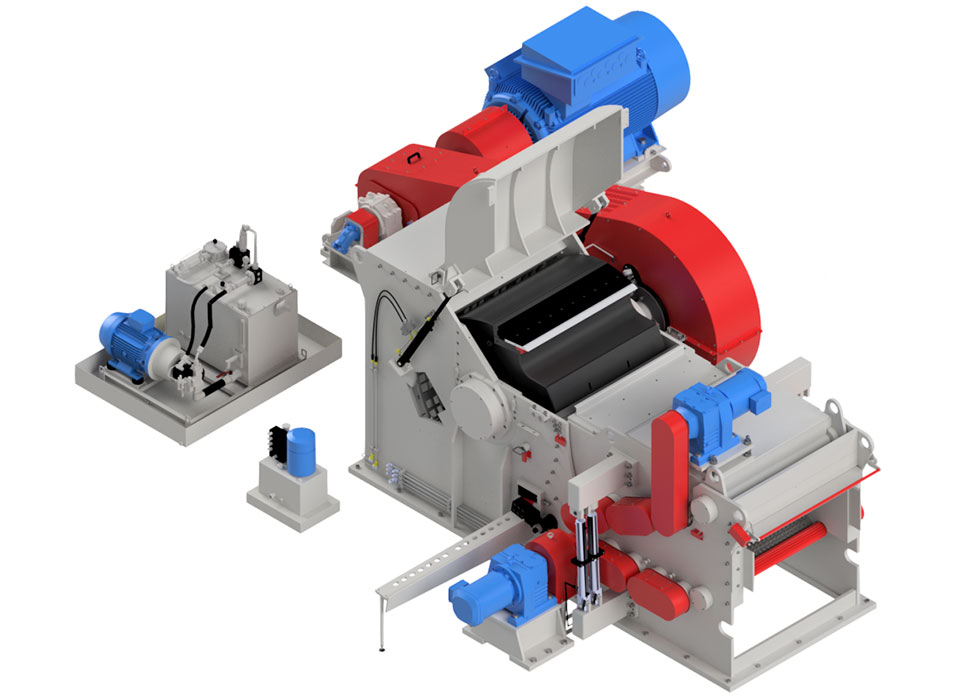

Innovative centrifugal strander mill for ultra-flat strands with high flexibility and low energy use

RevoStrand is designed to process a wide variety of wood materials into ultra-flat flakes and precision strands, ensuring optimal performance in downstream applications.

Uniform flake size and precise cutting

Optimized edge cutting reduces glue consumption

Consistent wear part consumption

Wood based panels

PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Applications and advantages of RevoStrand centrifugal strander mill

RevoStrand centrifugal strander mill by Globus Srl is an innovative solution for the production of high-quality wood strands used in OSB, SLPB, and lightweight structural panels.

Engineered with cutting-edge technology and Italian precision, it guarantees consistent strand geometry, excellent flake orientation, and optimized energy efficiency.

This innovation is designed to optimize the production of OSB (Oriented Strand Board) and SLPB (Super Light Particle Board), bringing greater efficiency and flexibility to the modern panel industry.

RevoStrand is capable of processing input materials up to 300 mm in length and 100 mm in diameter, allowing for highly flexible raw material management.

In contrast to traditional systems such as Knife Ring Flakers, Strander Discs, RevoStrand centrifugal strander mill produces high-quality flakes and strands from a broad spectrum of feedstock, including:

- Slabs, cut edges, core peeler

- Branches and twigs

- Small logs

- Recycled wood such as pallets or sawmill beams

This versatility allows panel producers to achieve higher yields, reduce raw material waste, and expand their usable input range — all with excellent strand quality and dimensional consistency.

| REVOSTRAND 12.450 15-6 |

REVOSTRAND 14.490 20-8 |

REVOSTRAND 20.490 36-16 |

|

|---|---|---|---|

| CAPACITY | Up to 3 t/h b.d. | Up to 6 t/h b.d. | Up to 12 t/h b.d. |

| KNIFE RING DIAMETER | 1200 mm | 1400 mm | 2000 mm |

| KNIVES | 15 | 20 | 36 |

| COUNTERKNIVES | 6 | 8 | 16 |

| KNIVES DIMENSION | 450 x 70 x 5 mm | 490 x 70 x 5 mm | 490 x 70 x 5 mm |

| AVARAGE POWER REQUIRED | 125 kW | 200 kW | 355 kW |

| RECOMMENDED MOTOR | 200 kW | 250 kW | 400 kW |

Ultra-flat flakes and strands

Ideal for OSB and SLPB

Innovative centrifugal stranding solution

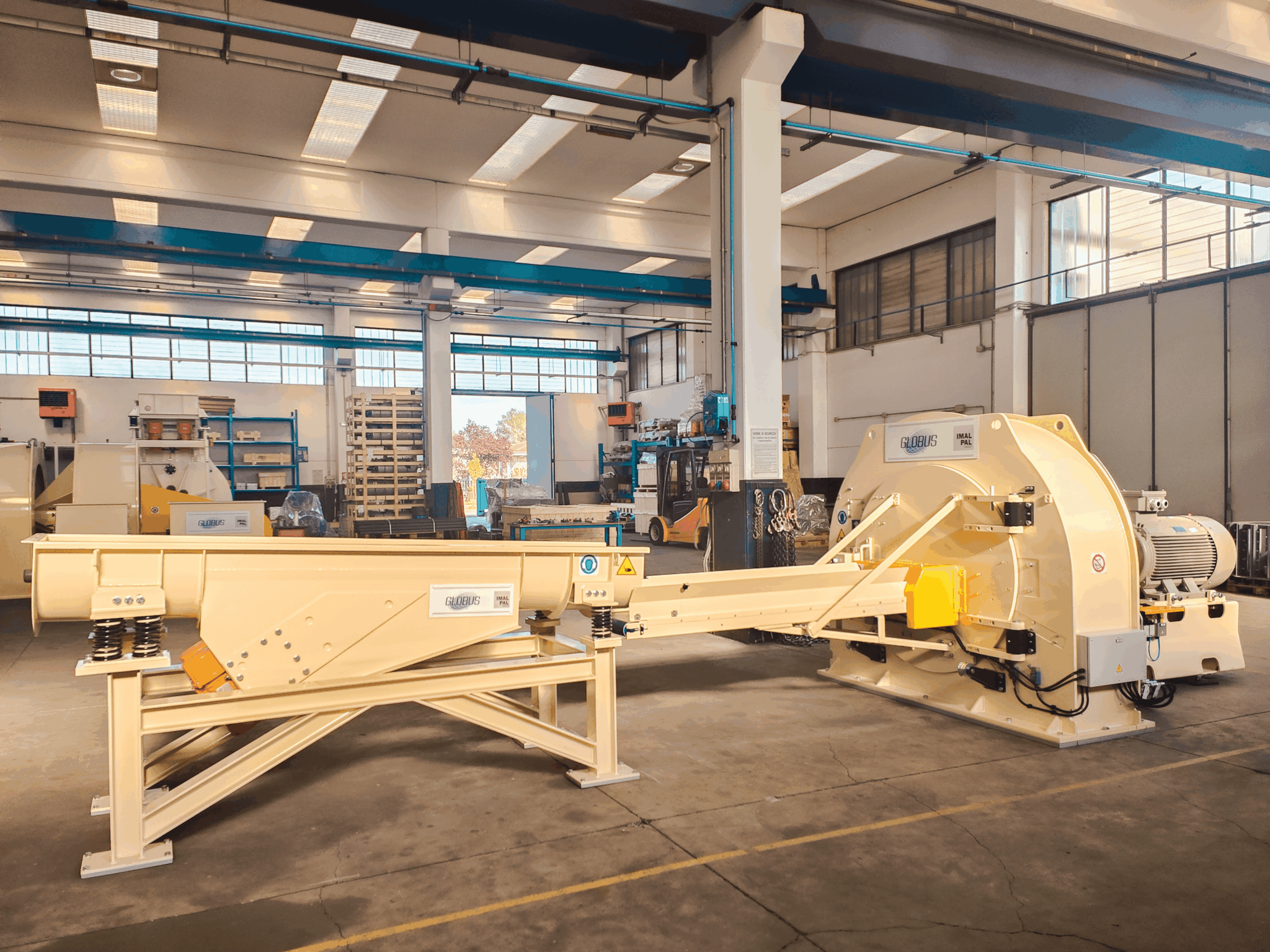

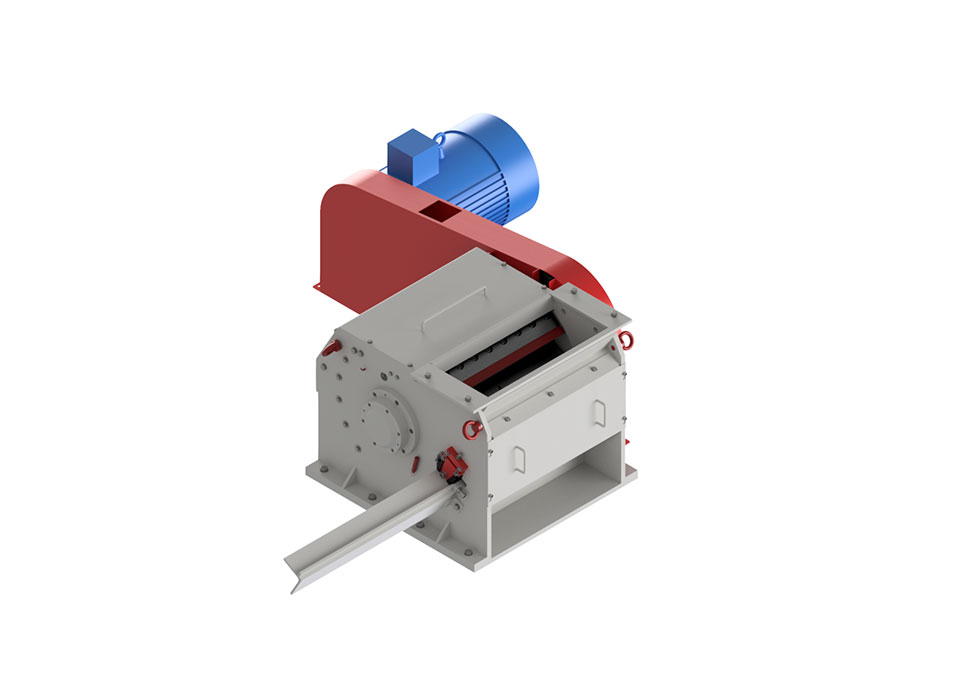

Technical features

Processes materials up to 300 mm in length and 100 mm in diameter - Ideal for superchips, sawmill waste, pallets, slabs, core peelers, and branches

Handles wood with bark and small contaminant traces (e.g., metal) - More flexibility than Knife Ring Flakers or Strander Discs

Not require long or large-diameter logs - Efficiently processes small logs with consistent results

Customizable knife and counterknife configuration - Optimizes particle size to meet customer specifications

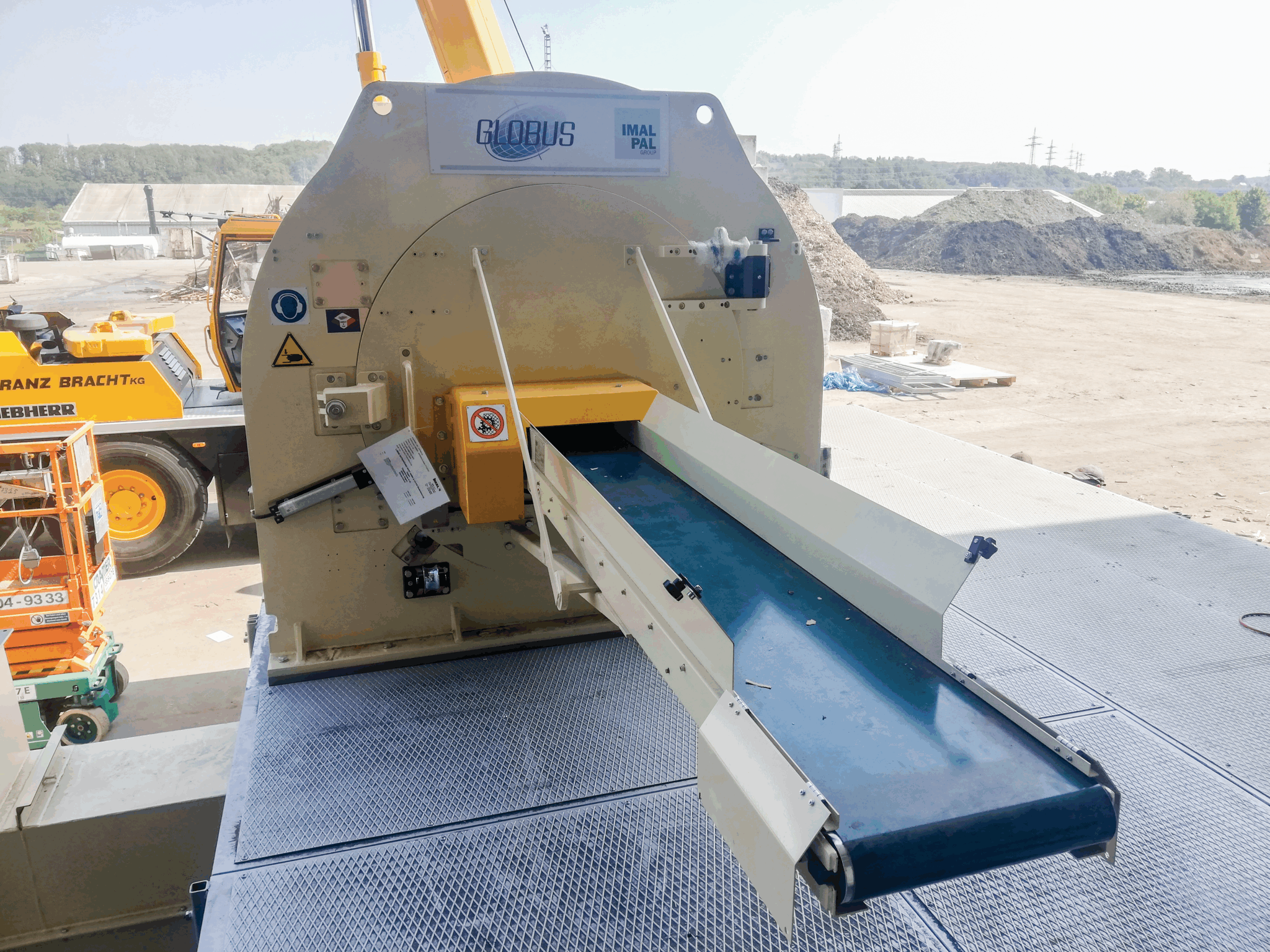

Optimized feeding system - Integrated transport ensures steady material flow

Low dust generation - Precise cutting reduces fine particles, increasing efficiency and product quality

High-precision rotor with pre-adjustment - Ensures stability and cutting uniformity, delivering repeatable performance

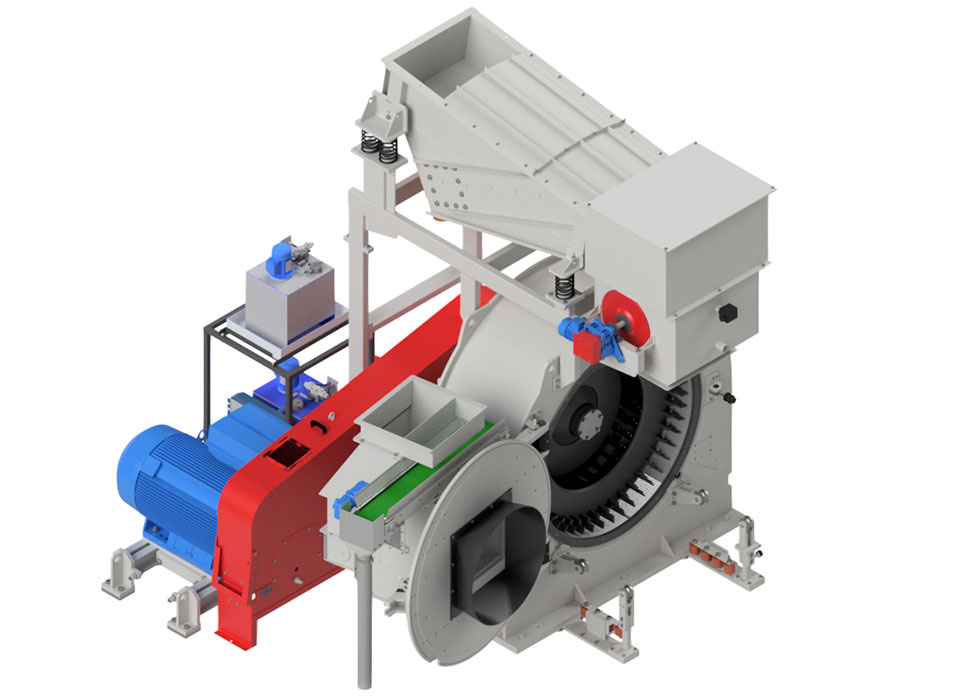

High Precision Centrifugal Cutting System

The RevoStrand mill uses a patented centrifugal principle to achieve superior cutting accuracy. Wood blocks are accelerated by centrifugal force and precisely cut by high-speed knives, ensuring optimal strand thickness and minimal waste.

This technology results in a uniform strand shape, ideal for OSB, LSB, and SLPB production.

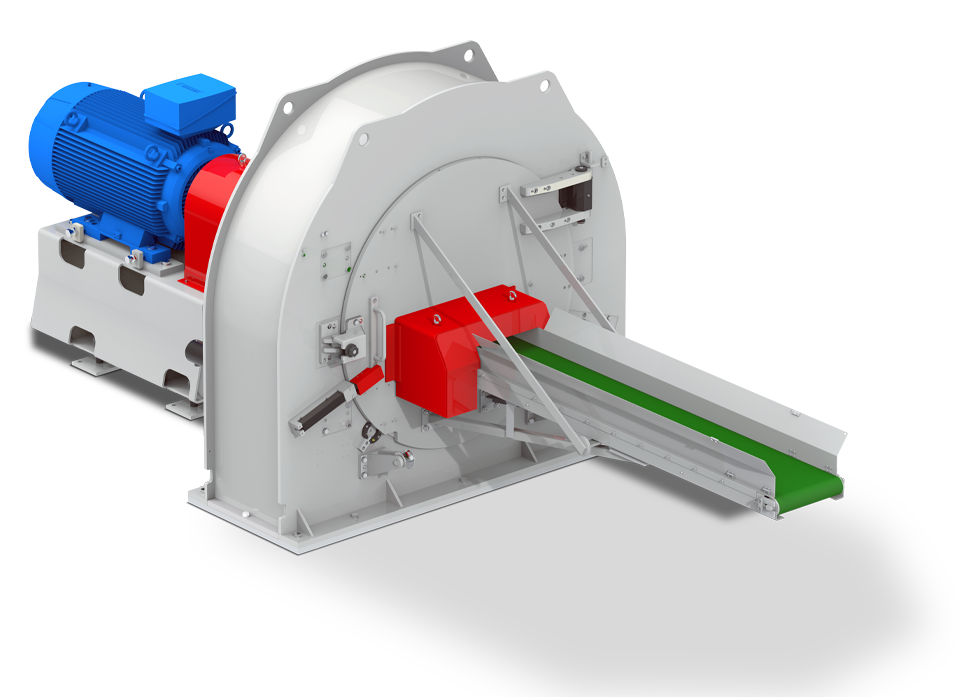

Optimized Energy Consumption and Maintenance

Compared to conventional stranders, the RevoStrand guarantees lower power consumption, reduced wear, and simplified maintenance.

The robust construction and aerodynamic design minimize vibration and heat generation, extending machine life and ensuring reliable 24/7 operation.

Smart Material Handling and Automation

Feeding and discharge systems are designed for continuous operation and perfect material distribution. Optional SmartBox PLC control provides automatic monitoring of vibration, temperature, and knife wear, allowing predictive maintenance and higher productivity.

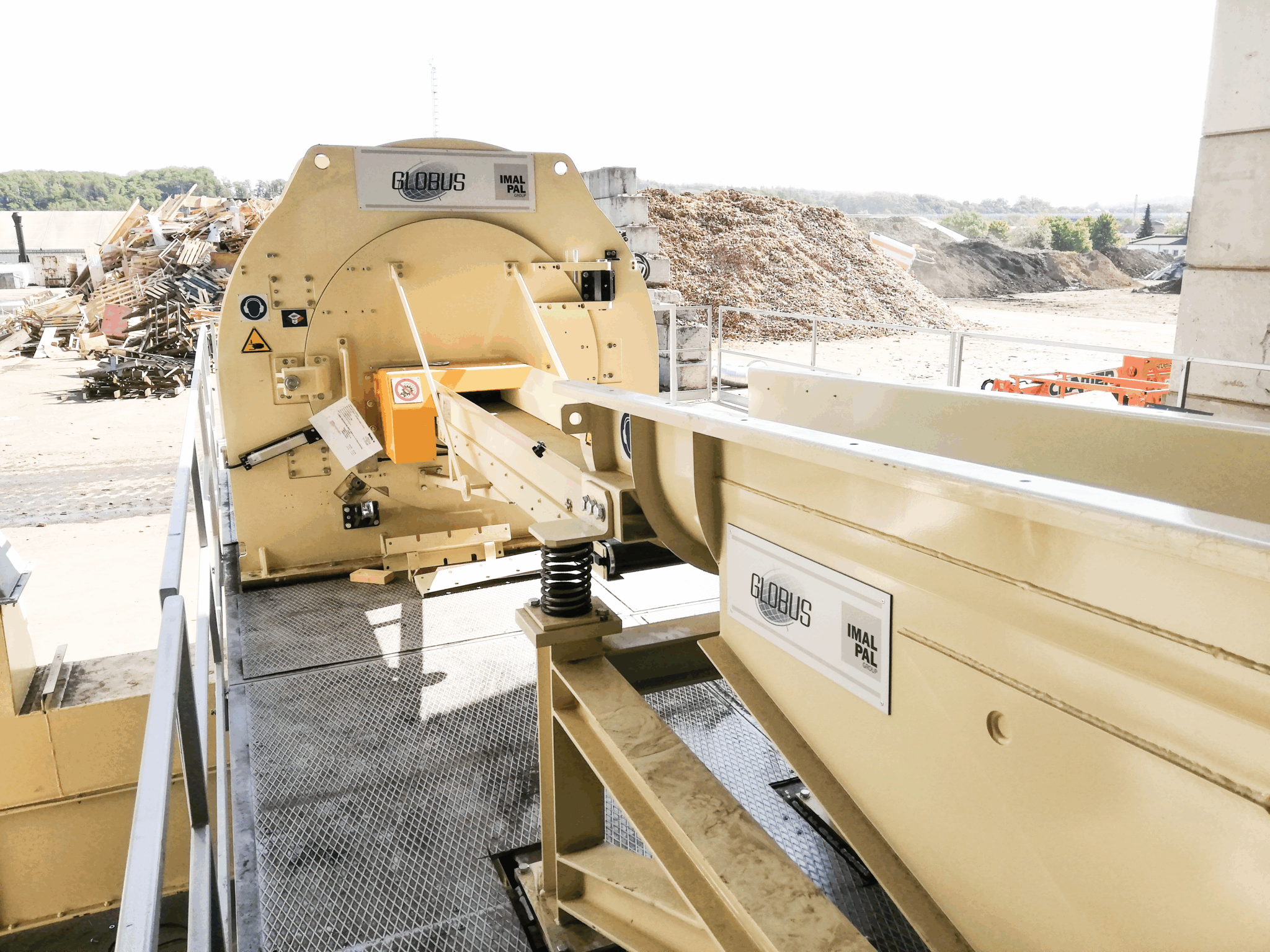

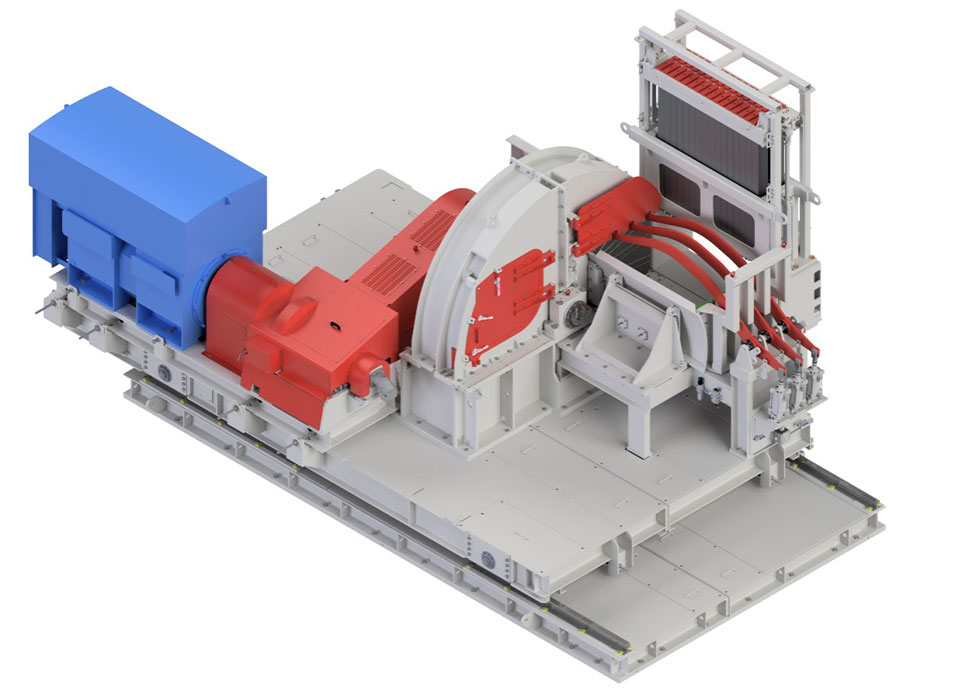

Integration in Complete Wood Preparation Lines

The RevoStrand centrifugal strander mill integrates seamlessly with other Globus machines, such as the MTG Drum Chipper for pre-chipping operations and the SRC Knife Ring Flaker for fine wood refining, forming complete wood preparation systems for panel production.

Designed and manufactured in Italy, the RevoStrand represents innovation, precision, and sustainability, marking the next generation of centrifugal stranding technology for the wood-based panel industry.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.