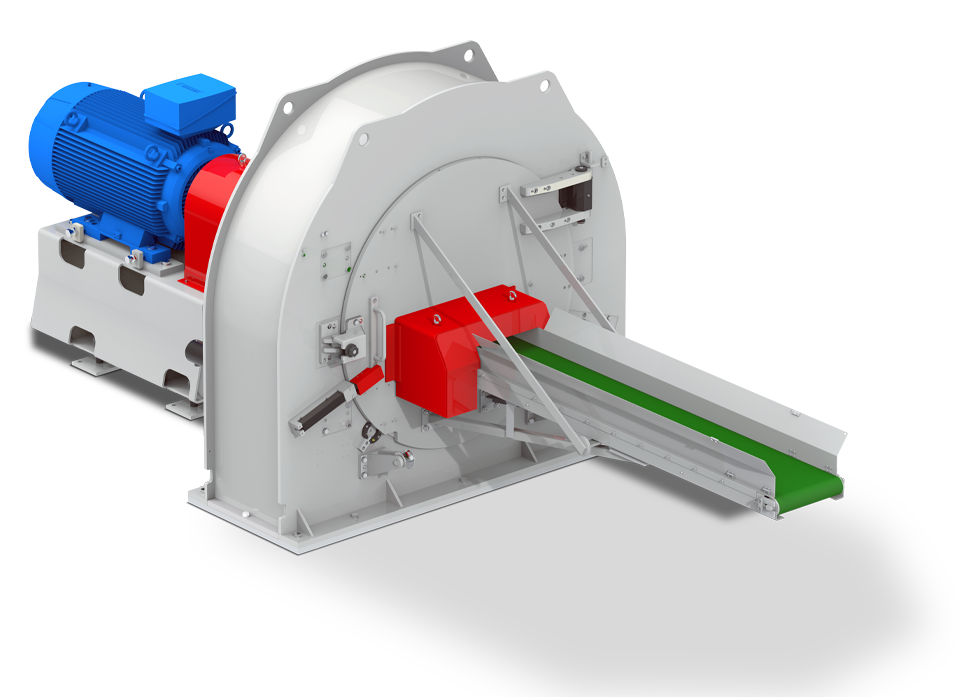

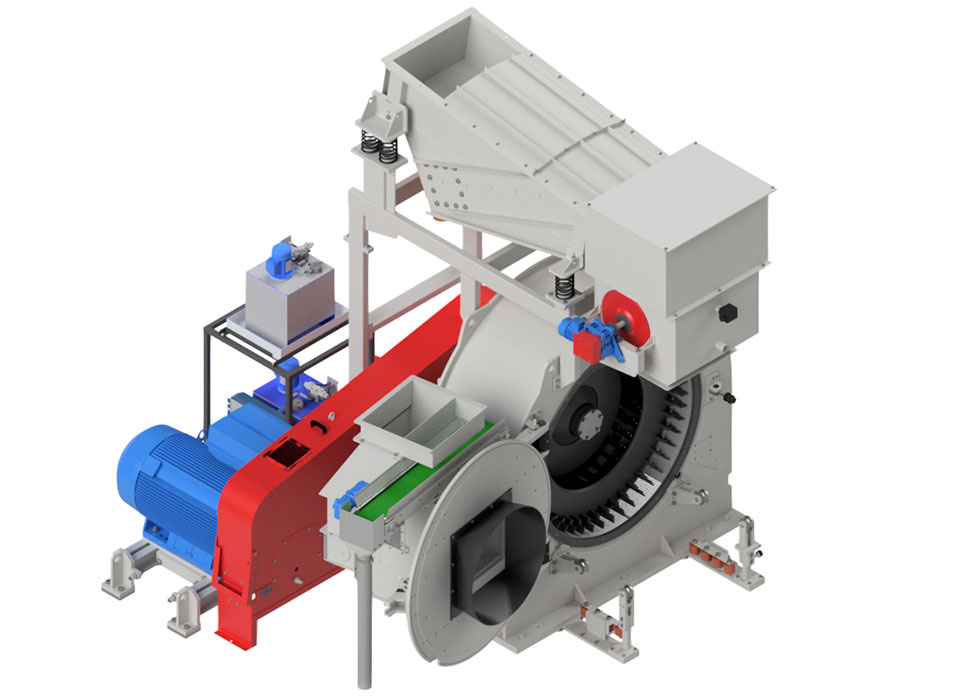

MSG – Centrifugal Mill

Centrifugal mill is an advanced refining solution designed for the production of high-quality dry flakes

MSG innovative dual-screen support system, quick-change mechanism, and energy-efficient operation make it a highly versatile and cost-effective choice for modern wood-processing applications.

Adaptable for dry processing

Versatile screens options

Quick ring replacement

Wood based panels

PB/SPB & OSB/LSB/FOSB

Applications and advantages of MSG Centrifugal Mill

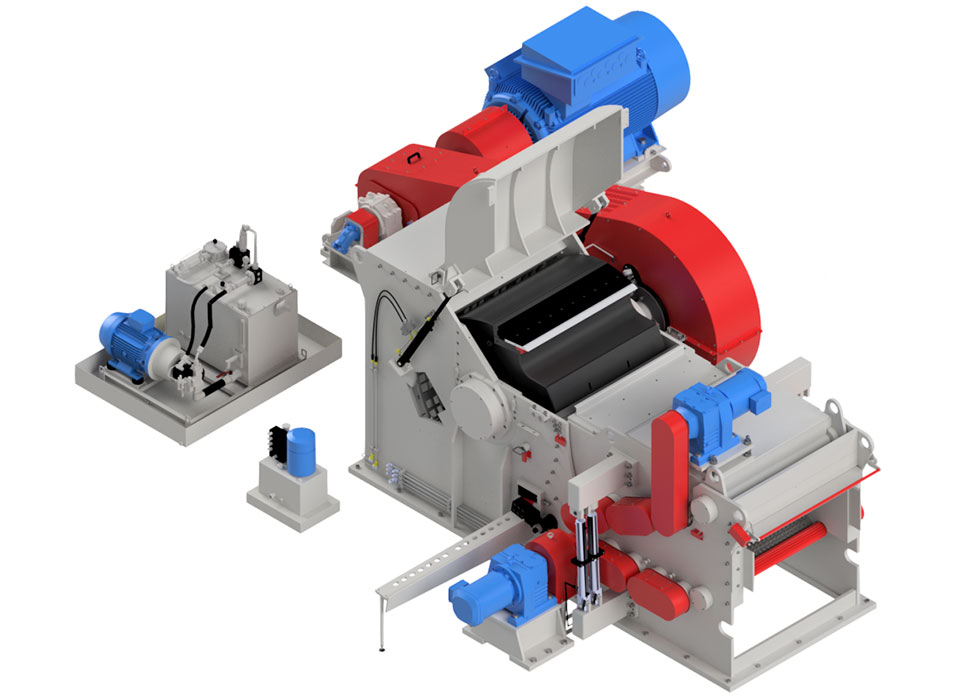

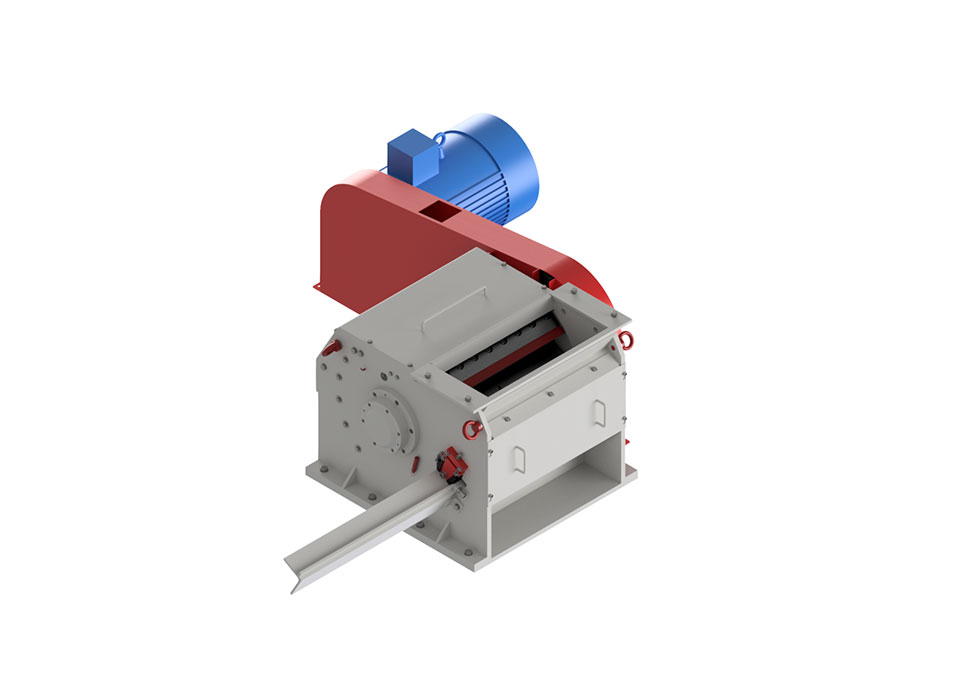

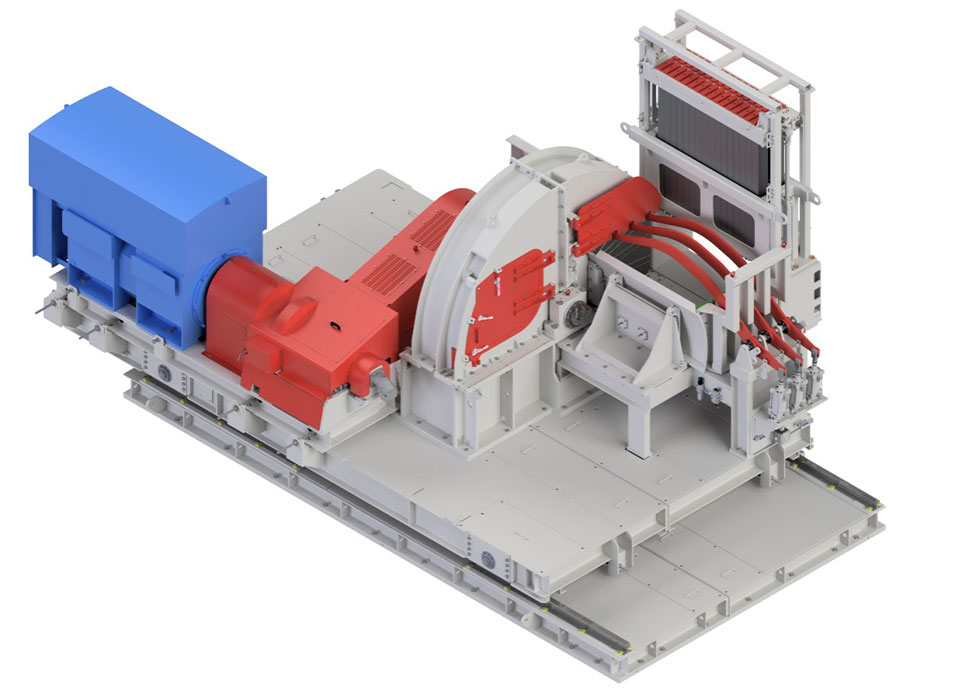

MSG centrifugal mill by Globus Srl is a high-performance refining machine designed for the production of dry flakes used in particleboard, OSB, and LSB panel manufacturing.

It is ideal for achieving fine, homogeneous flake sizes for both surface and core layers, ensuring maximum board quality and energy efficiency.

This industrial centrifugal mill features a robust construction and a high-speed rotor that guarantees stable performance, consistent material flow, and minimal vibration.

Its dual-screen configuration allows optimized separation and precise control over final particle size distribution, resulting in perfectly refined dry flakes and reduced waste generation.

Globus MSG centrifugal mill integrates perfectly with upstream and downstream equipment such as SRC Knife Ring Flaker and the MTG Drum Chipper, creating a complete wood preparation system for panel production.

| MSG 1200-610 | MSG 1500-760 | |

|---|---|---|

| ROTOR DIAMETER | 1200 mm | 1500 mm |

| GRINDING SECTOR WIDTH | 225 mm | 265 mm |

| SCREEN WIDTH | 2 x 180 mm | 2 x 225 mm |

| RECOMMENDED MOTOR | 160/200 kW | 250/315 kW |

Adaptable for dry processing

Dual ring support system

Quick ring replacement in just 8 minutes

Technical features

Dry flake refining mills designed for surface and core layer processing in particleboard production

Dual ring support system, compatible with Conidur Ring and Slotted Hole Ring featuring four cutting edges for enhanced performance

Quick ring replacement in just 8 minutes, thanks to a special hydraulic changing system

Automated oil lubrication system for main bearing longevity and reduced maintenance

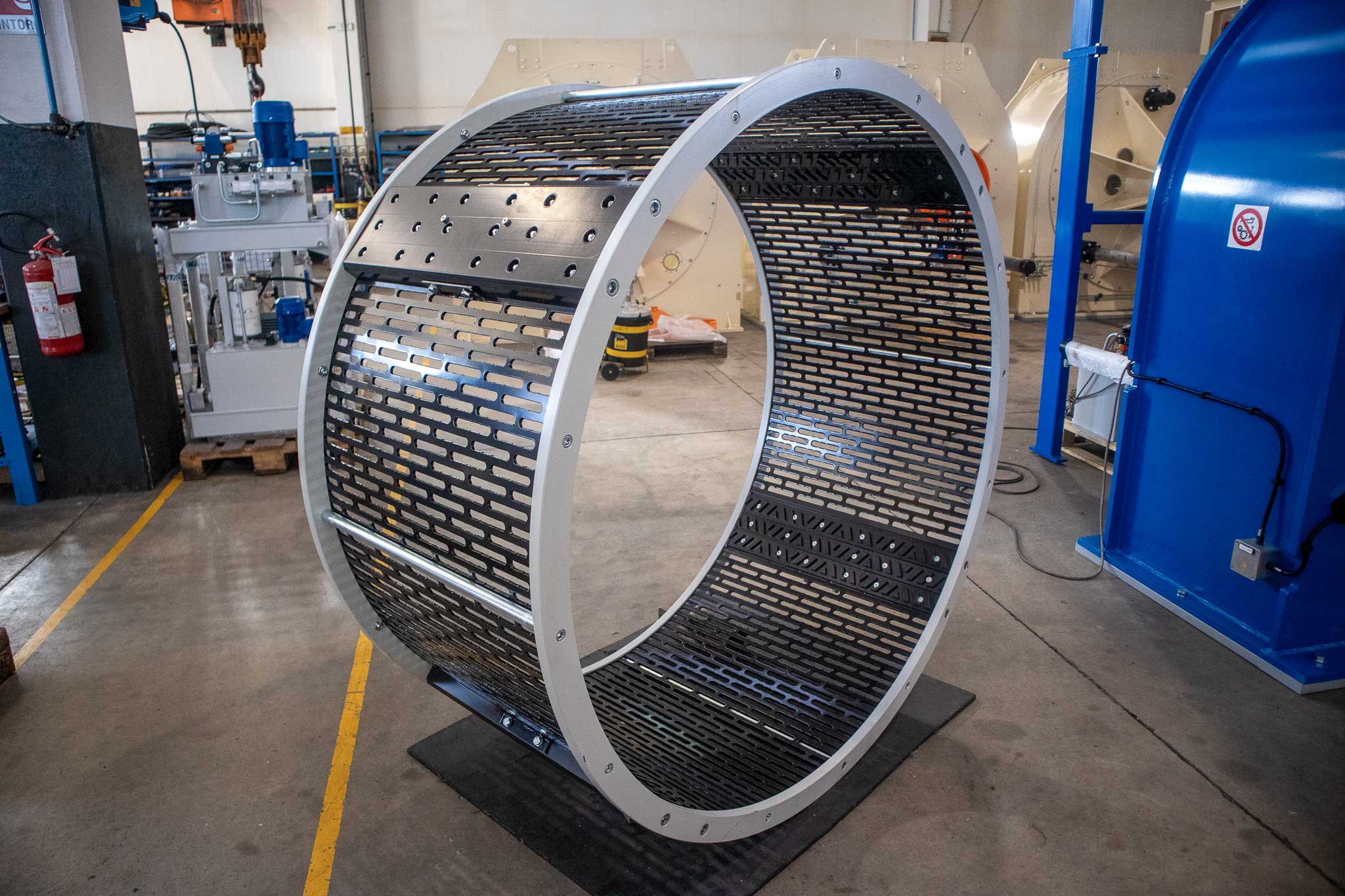

Conidur Ring or Slotted Hole Ring

MSG centrifugal mill is equipped with a dual-screen system, allowing for precise particle refinement and enhanced operational flexibility. It features both Conidur Ring for efficient fine grinding and Slotted Hole Ring for optimized material flow, ensuring superior separation and uniformity. This innovative configuration enables manufacturers to achieve high-quality flakes tailored to specific production requirements, improving overall panel performance.

Conidur ring

Conidur Ring features a finely perforated surface that ensures superior particle refinement, making it ideal for producing high-quality flakes for surface layers.

Slotted Hole Ring

Slotted Hole Ring is engineered to optimize material flow and throughput, allowing for efficient processing of coarser particles, particularly suited for core layer applications.

Centrifugal mill for dry particles in particleboard production.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.