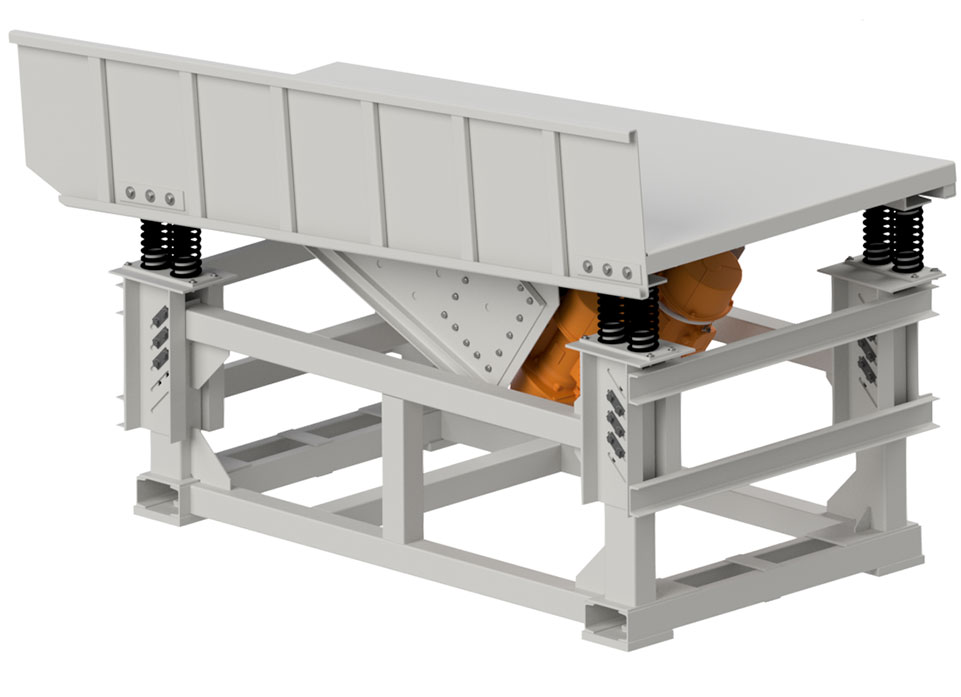

VTG – Vibrating Table

Modular design to combined multiple vibrating tables in parallel

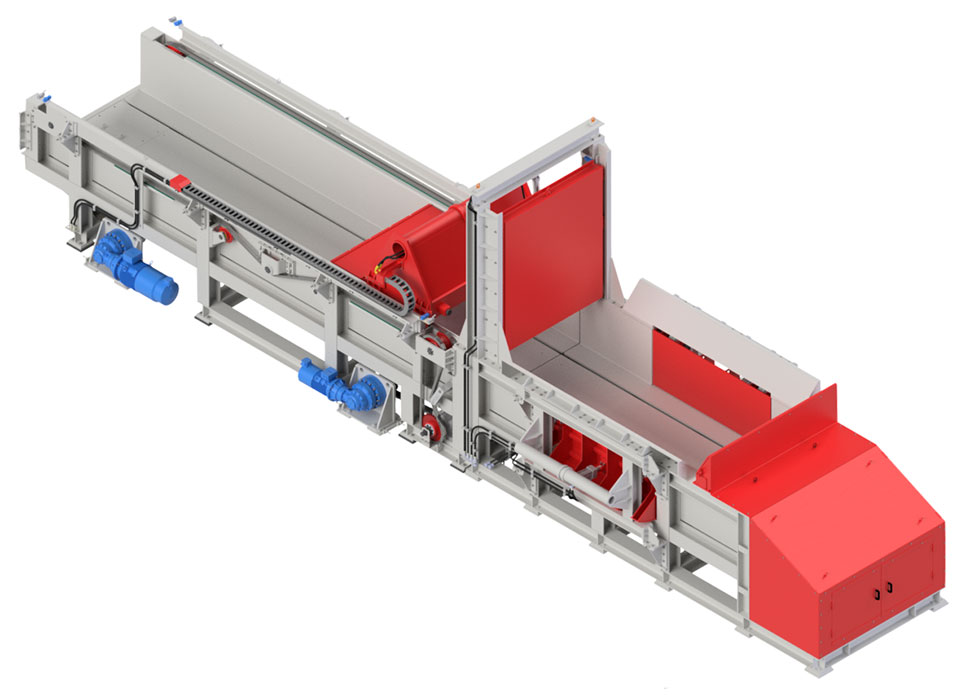

VFG is designed to ensure a smooth and continuous wood material feeding process, enhancing the efficiency of downstream operations.

Modular configuration, allowing multiple vibrating tables to be combined for the desired feeding surface

Unidirectional movement, powered by two motovibrators, ensuring a constant and uniform feed

Optional separation grid, for the removal of bark, stones, and fine materials

Robust structure, designed to minimize vibrations and optimize operational durability

Wood based panels

MDF/HDF PB/SPB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets and black pellets, green fuels and biomass

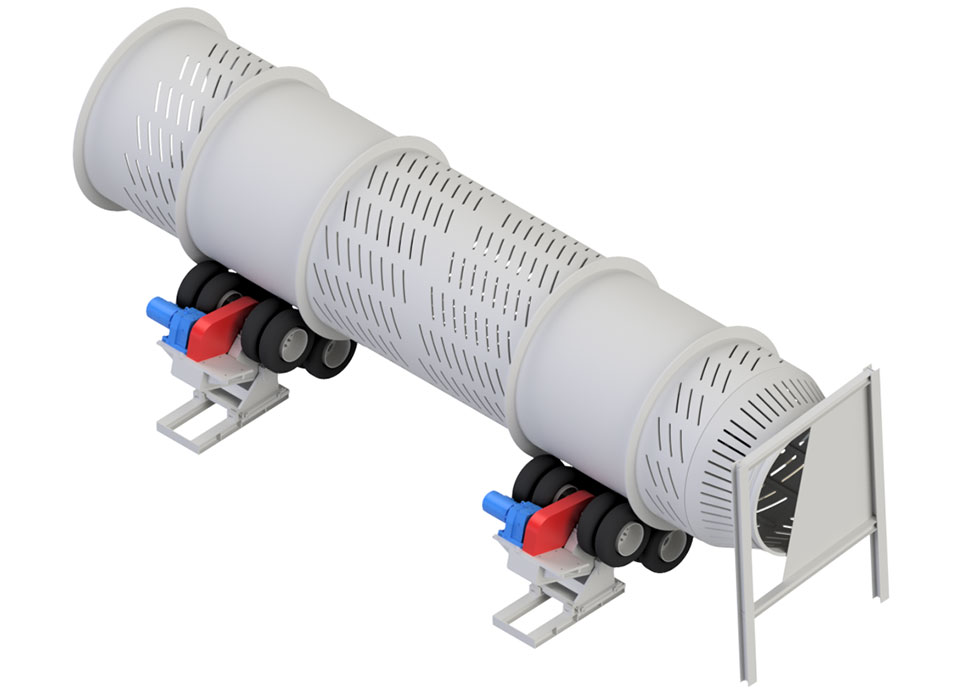

Wood recycling and waste treatment

Costumized solutions for recycling

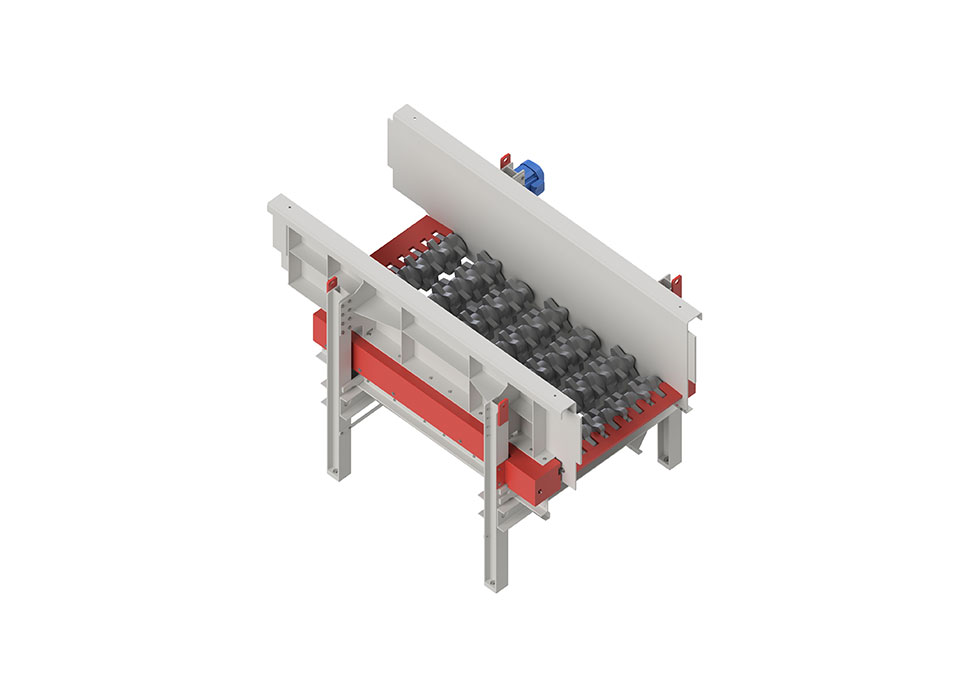

The modular design is tailored to the customer’s specific production requirements

Built for uniform material feeding, the unidirectional movement, powered by two motovibrators, ensures uniform material distribution, preventing blockages and irregular flow.

With its modular design, LCG can be easily extended or adapted to meet evolving production needs. It is available in various lengths, widths, and chain configurations, making it a versatile solution for different chipping lines.

The modular design allows multiple vibrating tables to be combined in parallel, adjusting the configuration to meet the required production capacity. This solution enables larger feeding surfaces, ensuring optimal material flow towards cutting or processing systems.

Additionally, VTG tables can be equipped with an optional separation grid, which helps remove fine materials such as bark, stones, and dust, improving the purity of the incoming material.

“The system configuration is tailored to the customer’s specific production requirements, taking into account the wood type, piece dimensions, and required material flow.”

Uniform material feeding

Customizable configuration

Modularity and flexibility

Modular design to meet evolving production needs

Modular configuration, allowing multiple vibrating tables to be combined for the desired feeding surface

Unidirectional movement, powered by two motovibrators, ensuring a constant and uniform feed

Optional separation grid, for the removal of bark, stones, and fine materials

Robust structure, designed to minimize vibrations and optimize operational durability

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.