RevoStrand

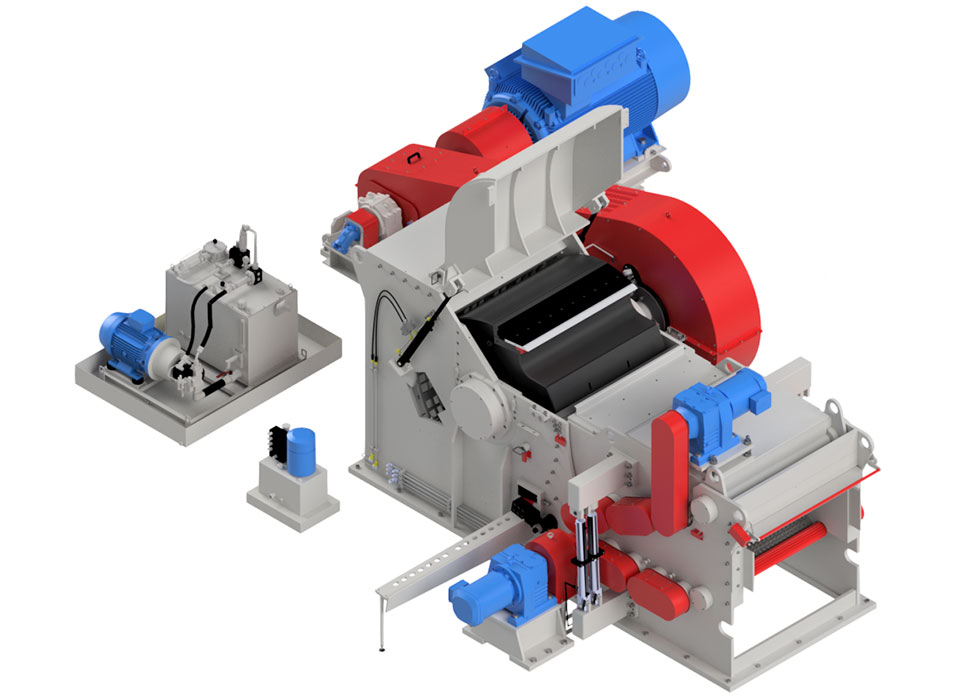

Innovative centrifugal stranding solution

RevoStrand is designed to process a wide variety of wood materials into ultra-flat flakes and precision strands, ensuring optimal performance in downstream applications.

Homogeneous flake granularity and precise wood cutting

Optimized edge cutting reduces glue consumption

Consistent wear part consumption

Wood based panels

PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

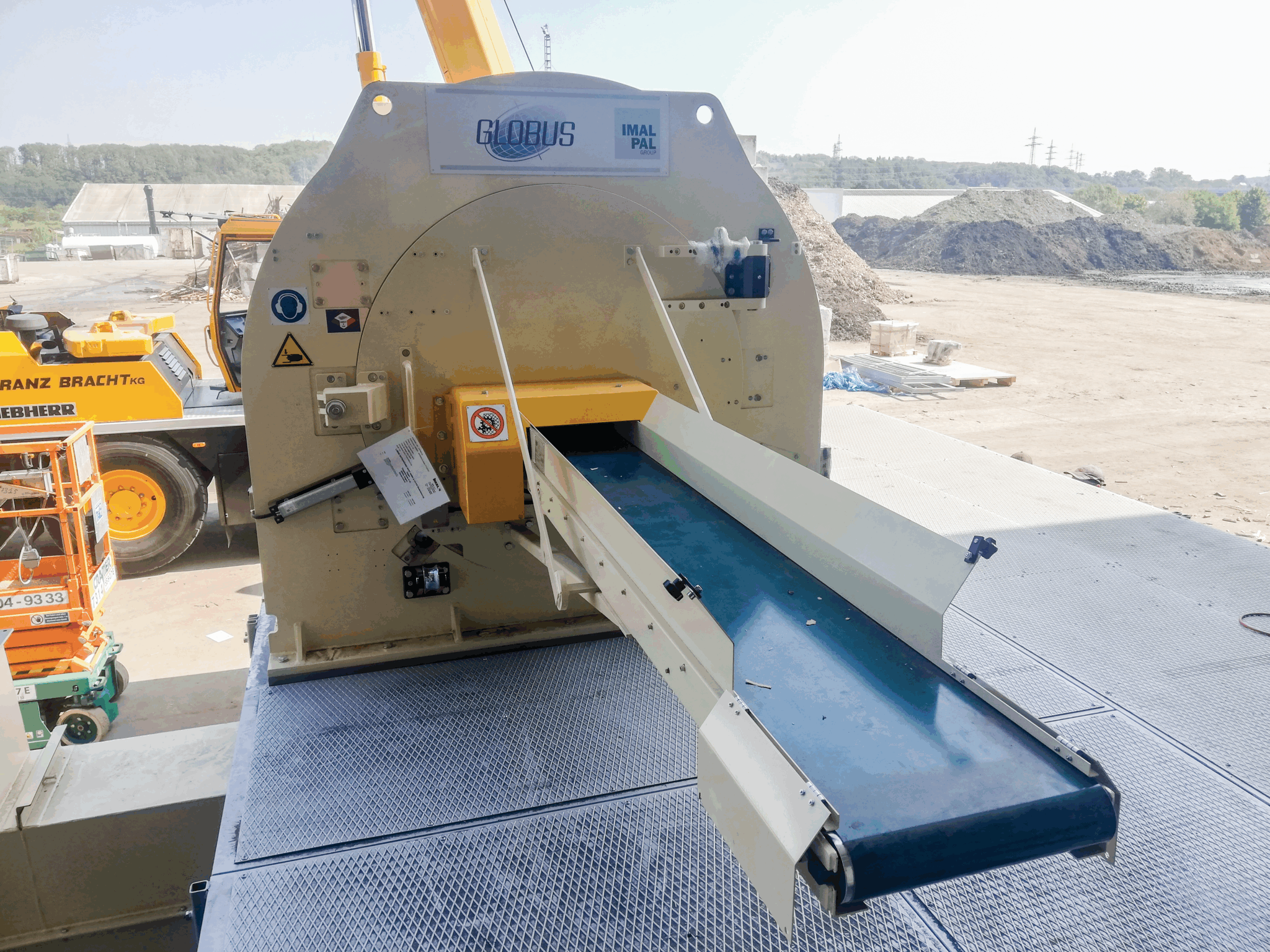

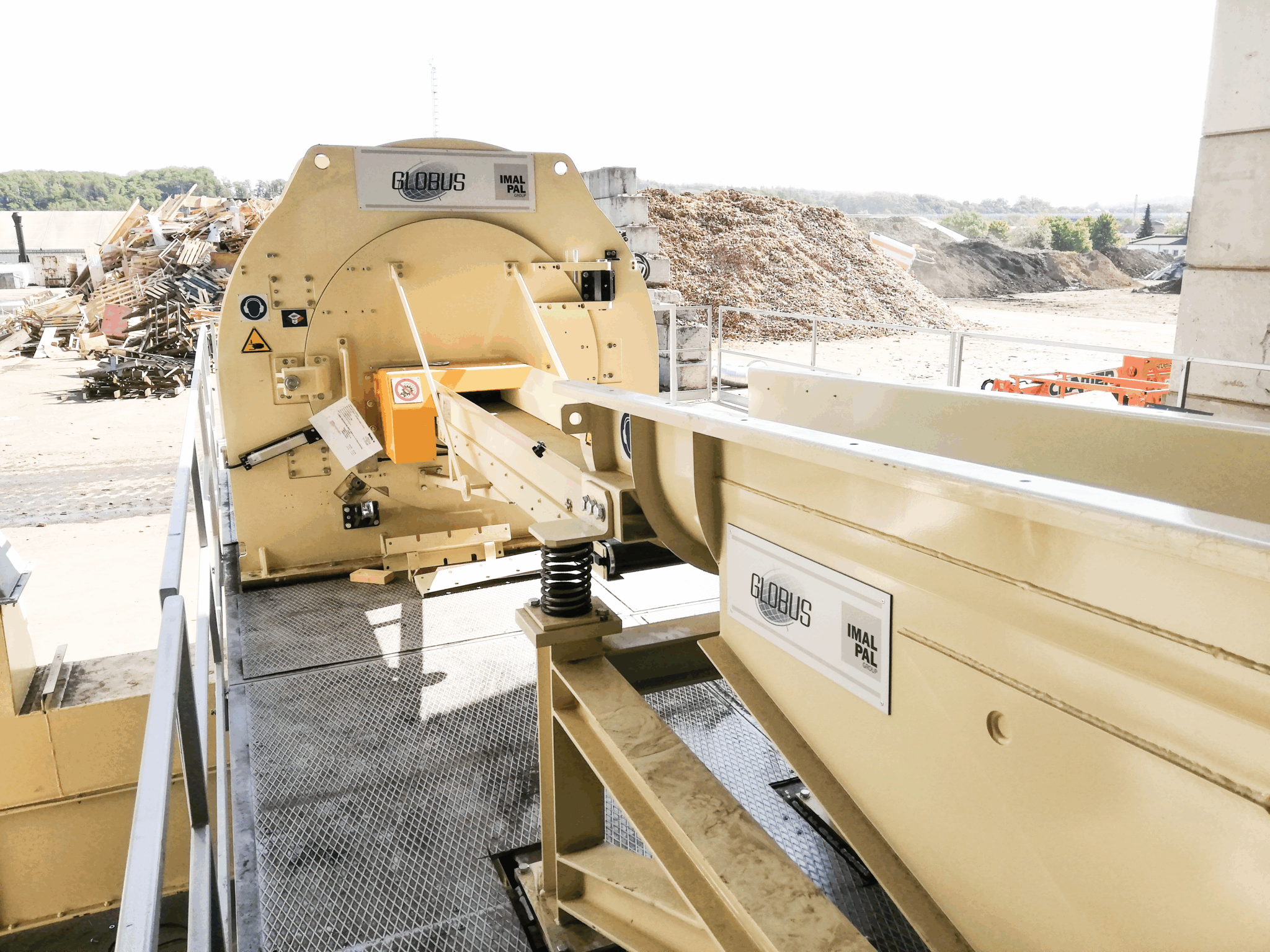

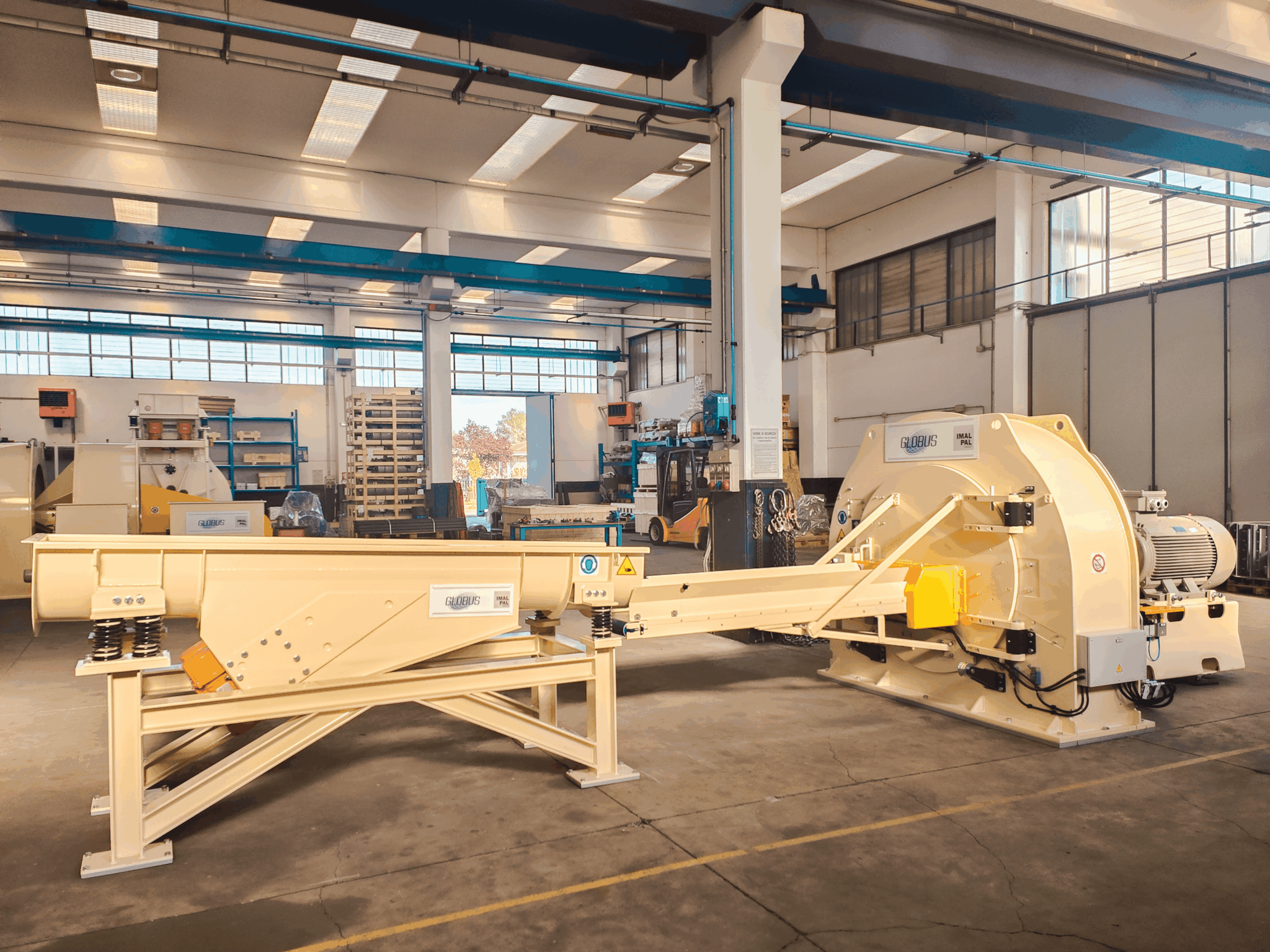

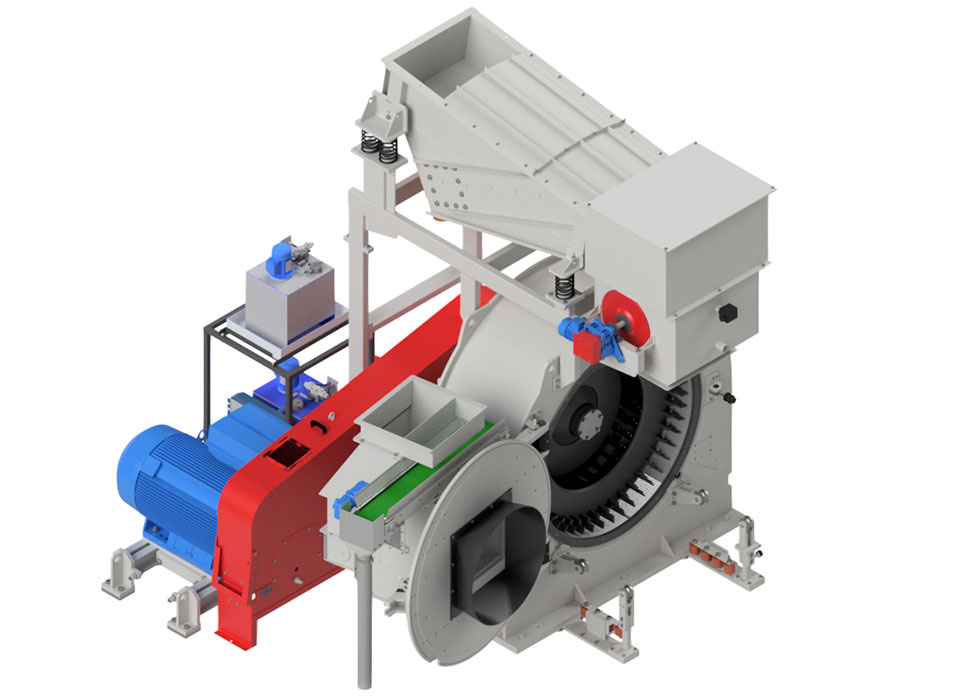

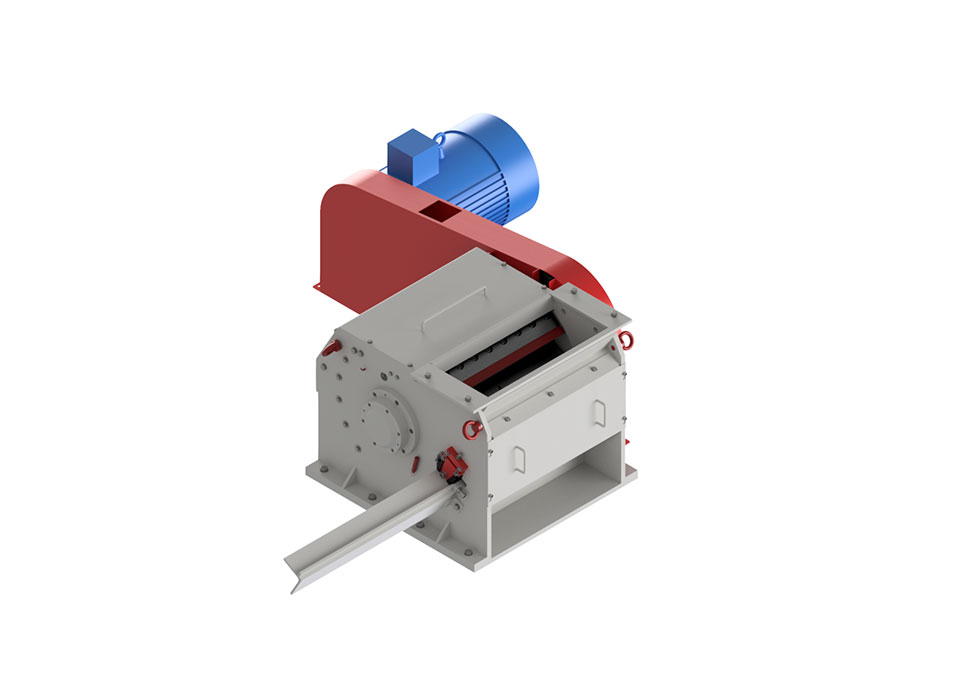

Centrifugal Strander Mill designed to ensure controlled and uniform granulometry

This innovation is designed to optimize the production of OSB (Oriented Strand Board) and SLPB (Super Light Particle Board), bringing greater efficiency and flexibility to the panel industry.

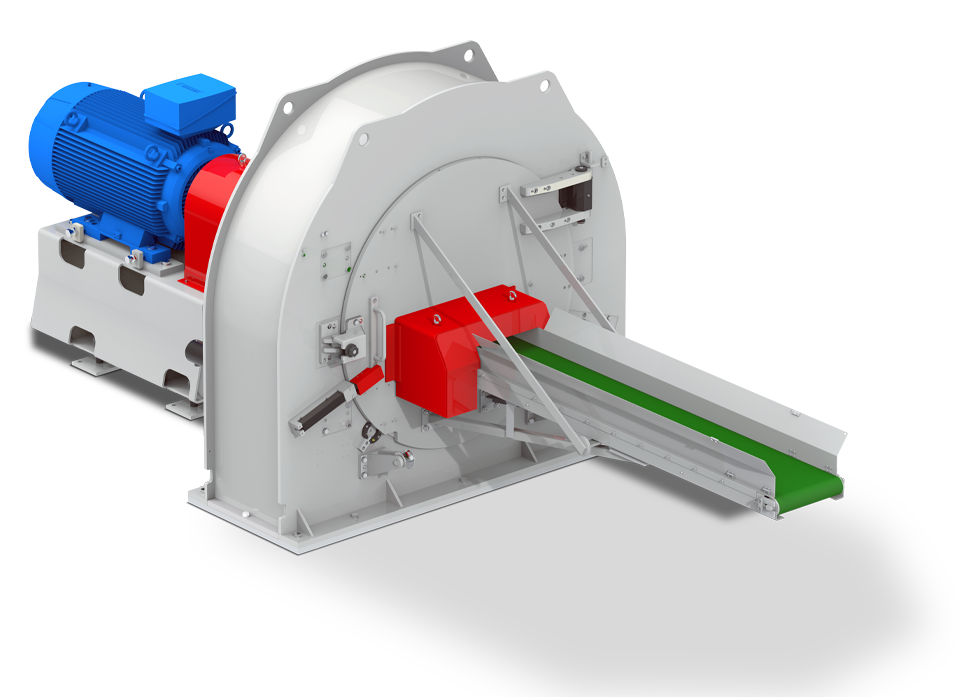

RevoStrand is capable of processing input materials up to 300 mm in length and 100 mm in diameter, allowing for highly flexible raw material management. In contrast to traditional systems such as Knife Ring Flakers, Strander Discs, or Rings, RevoStrand produces high-quality flakes and strands from a broad spectrum of feedstock, including:

- Slabs, cut edges, core peeler

- Branches and twigs

- Small logs

- Recycled wood such as pallets or sawmill beams

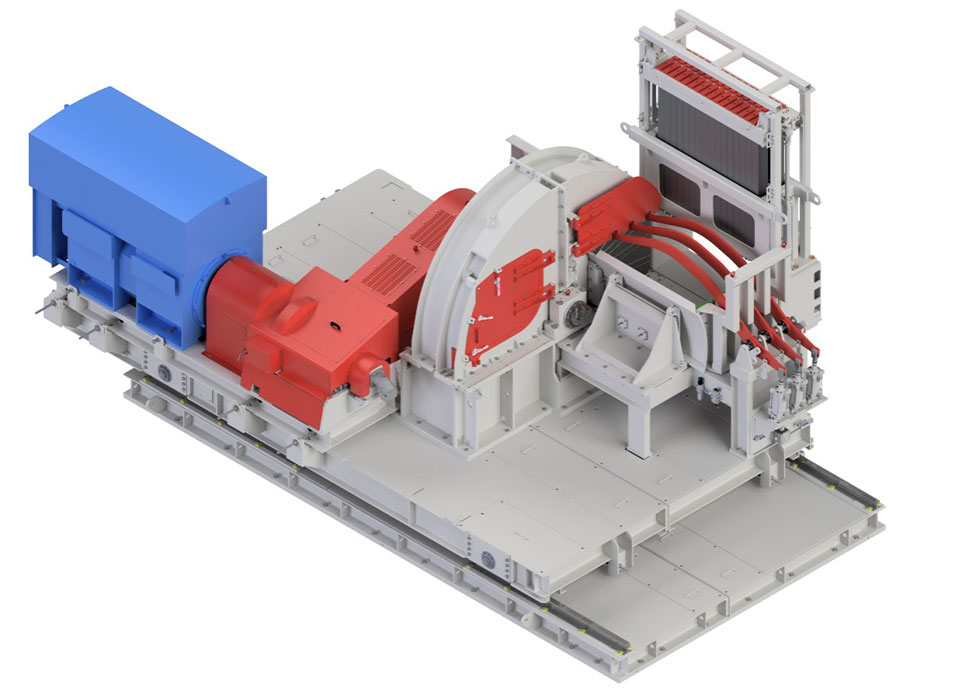

| REVOSTRAND 12.450 15-6 |

REVOSTRAND 14.490 20-8 |

REVOSTRAND 20.490 36-16 |

|

|---|---|---|---|

| CAPACITY | Up to 3 t/h b.d. | Up to 6 t/h b.d. | Up to 12 t/h b.d. |

| KNIFE RING DIAMETER | 1200 mm | 1400 mm | 2000 mm |

| KNIVES | 15 | 20 | 36 |

| COUNTERKNIVES | 6 | 8 | 16 |

| KNIVES DIMENSION | 450 x 70 x 5 mm | 490 x 70 x 5 mm | 490 x 70 x 5 mm |

| AVARAGE POWER REQUIRED | 125 kW | 200 kW | 355 kW |

| RECOMMENDED MOTOR | 200 kW | 250 kW | 400 kW |

Ultra-flat flakes and strands

Ideal for OSB and SLPB

Innovative centrifugal stranding solution

Technical features

Processes materials up to 300 mm in length and 100 mm in diameter - Ideal for superchips, sawmill waste, pallets, slabs, core peelers, and branches

Handles wood with bark and small contaminant traces (e.g., metal) - More flexibility than Knife Ring Flakers or Strander Discs

Not require long or large-diameter logs - Efficiently processes small logs with consistent results

Customizable knife and counterknife configuration - Optimizes particle size to meet customer specifications

Optimized feeding system - Integrated transport ensures steady material flow

Low dust generation - Precise cutting reduces fine particles, increasing efficiency and product quality

High-precision rotor with pre-adjustment - Ensures stability and cutting uniformity, delivering repeatable performance

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.