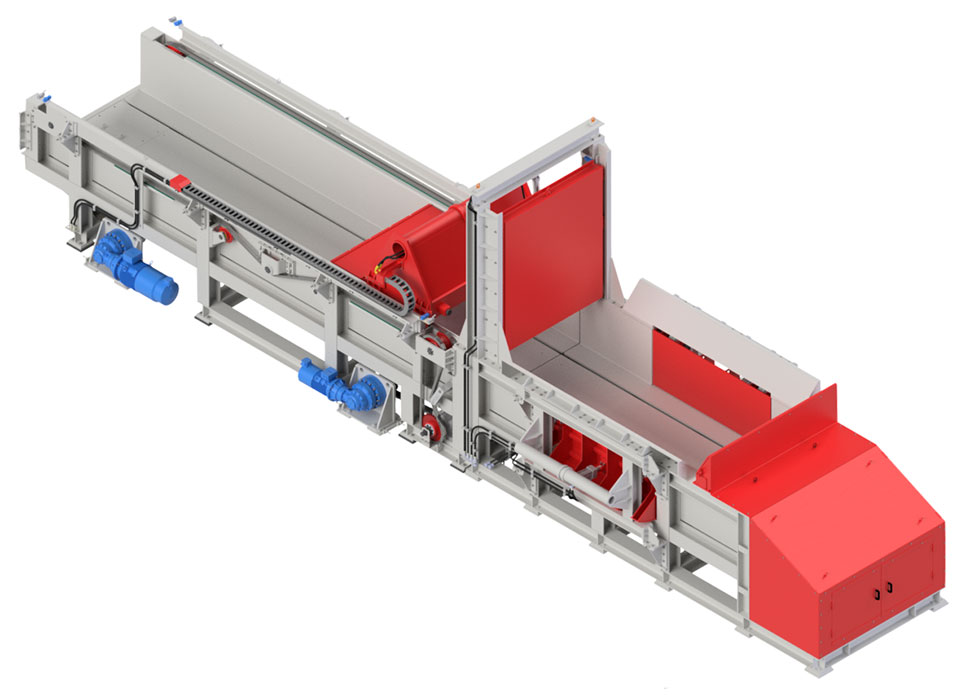

RDG – Roller Discharge

Flexible and modular design allows seamless integration into chipping lines.

RDG roller system is designed for log cleaning and pre-processing, ensuring a steady and continuous material flow to the next processing stages.

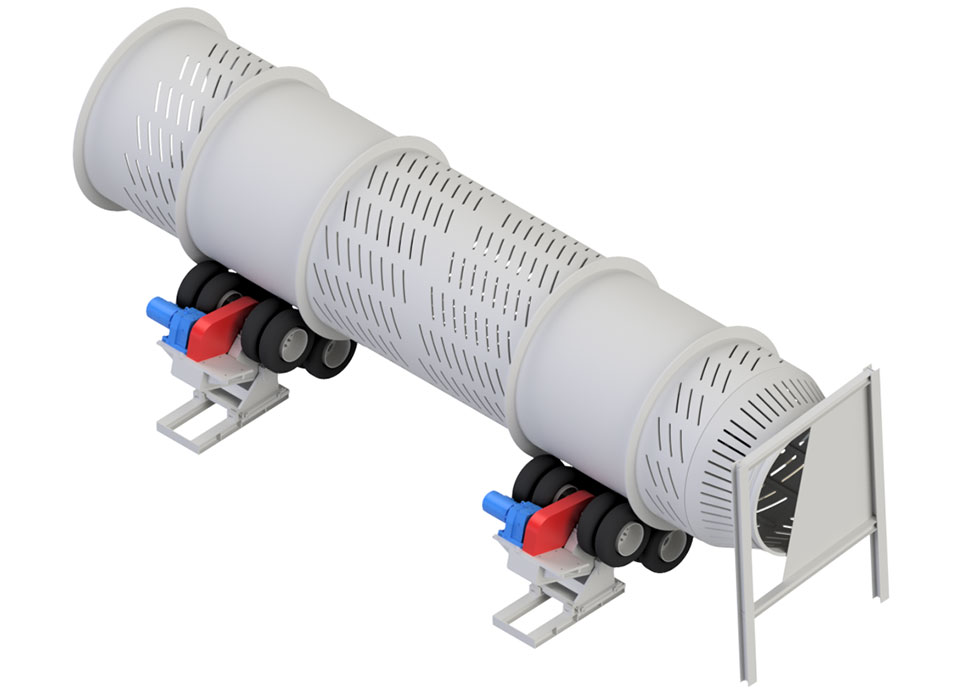

Efficient removal of bark, debris, and even snow in winter

Consistent and continuous material flow

Maximum flexibility

Easy integration into existing production lines, thanks to its modular design

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Green fuels and biomass, wood pellets and black pellets

Log cleaning and pre-processing, ensuring a steady and continuous material flow

RDG – Roller Discharge is a fully customizable roller system, available with over 10 different roller types, specifically configured based on log diameter and required cleaning level, ensuring effective separation of bark and debris.

RDG and CSC can be combined in the same line, maximizing cleaning efficiency and material feeding performance.

Thanks to the possibility of integrating multiple independent motors, these systems allow adjustable working speeds, optimizing material movement based on specific process needs.

Maximum flexibility

Efficient removal of bark

Consistent and continuous material flow

Customizable configurations based on wood type

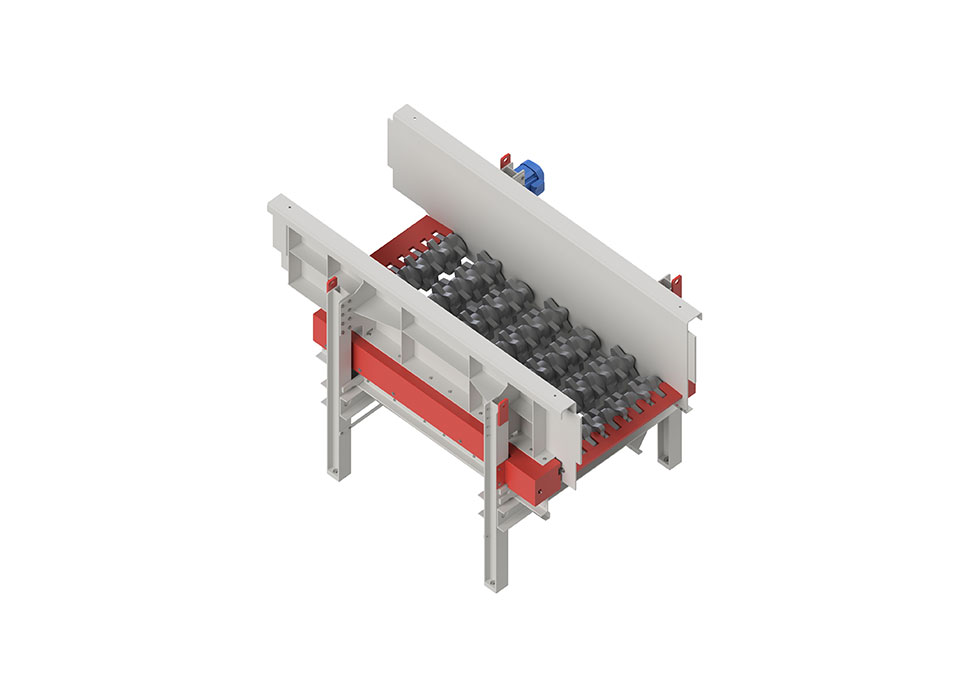

Steel star-shaft structure, available with interconnected disks (RDG) for efficient bark removal

Over 10 roller types available, customized based on log diameter and required cleaning level

Maintenance-free bearings and reinforced transmission, ensuring long operational life

Optimized design to minimize friction and wear, extending component durability

Adjustable working speed, with one or multiple independent motors for enhanced material flow control

Reversible material flow, providing greater flexibility and adaptability to the production line

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.