WMG – Knife Ring Washer

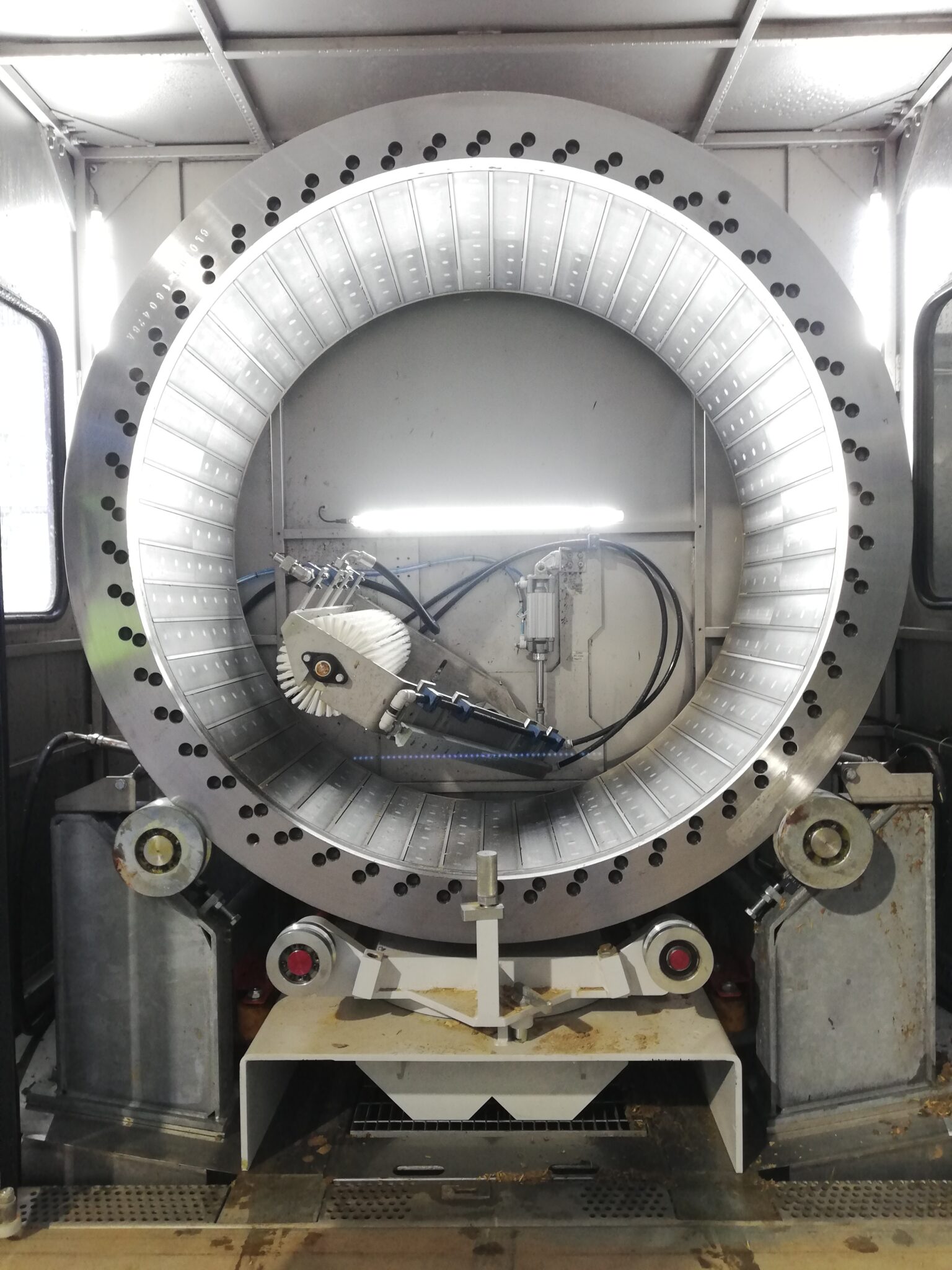

The sharpening cycle begins with the cleaning of the knife ring flaker

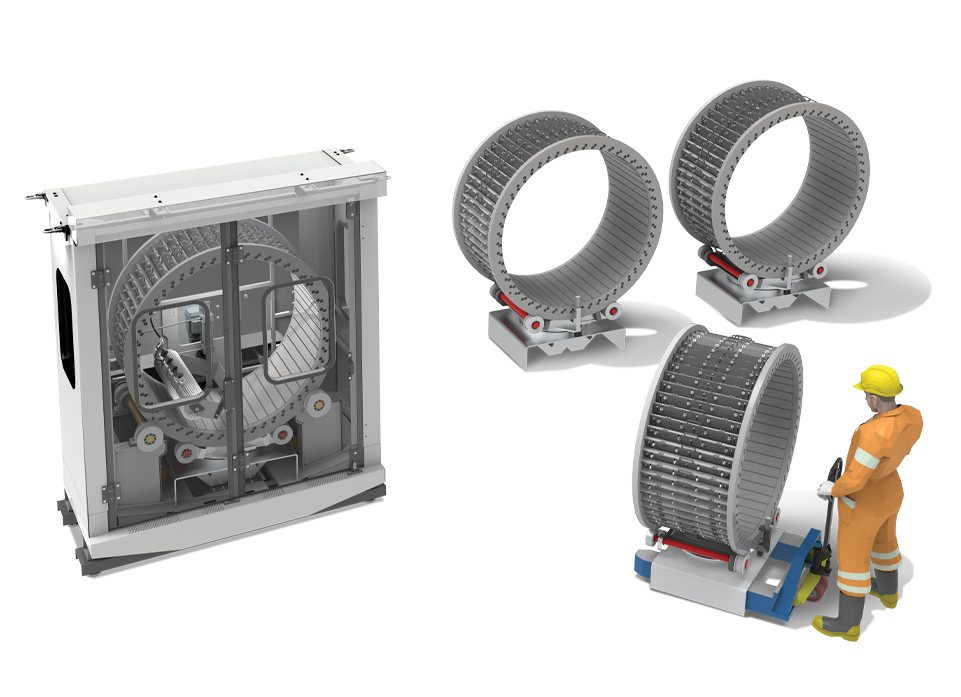

WMG is a high-efficiency washing machine, specifically designed for cleaning knife rings, combining power and precision in a fully automated process.

High-pressure system

Integrated cleaning brush

Wastewater collecting tank

Wastewater recovery system

High-pressure piston pump

Compressed air drying system

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Applications and advantages of WMG Knife Ring Washer

WMG knife ring washer by Globus Srl is an advanced washing unit designed for knife rings and flaker blades used in particleboard and wood-based panel production lines.

It ensures deep, precise cleaning of rings and blades, removing glue, resin, dust, and wood particles accumulated during operation.

Thanks to its high-efficiency design and automation, this industrial knife ring washer guarantees consistent cleaning quality, reduced water consumption, and minimal maintenance.

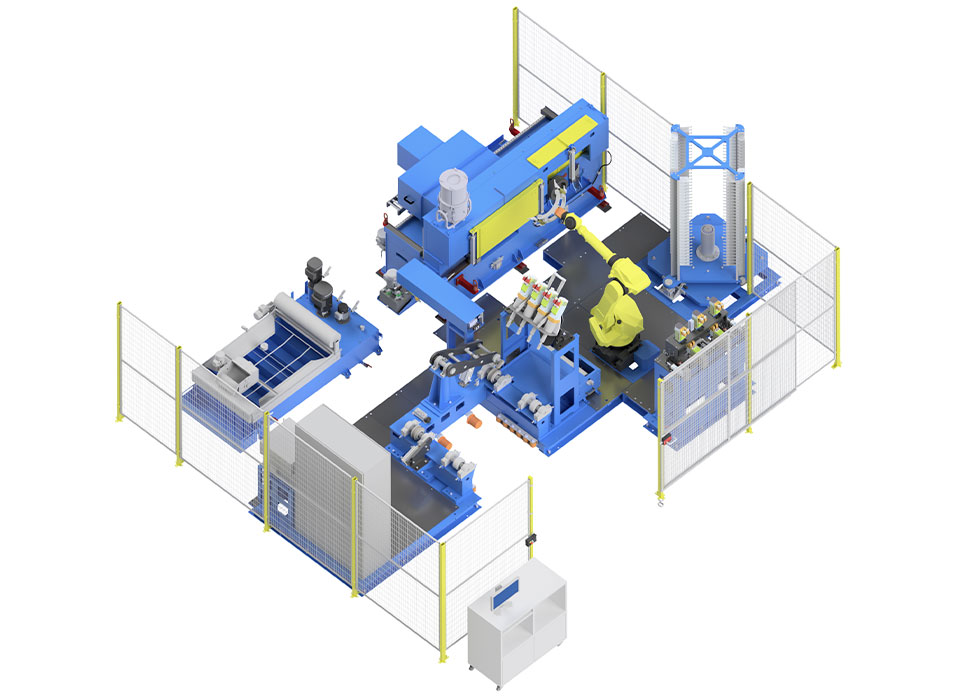

WMG is an essential component in any knife ring maintenance line, typically paired with the ASR Automatic Sharpening Room to ensure complete knife management — from washing to sharpening and reinstallation.

High-pressure system

Integrated cleaning brush

Wastewater recovery system

WMG knife ring washer delivers reliable and sustainable performance

High-pressure water jet system (up to 160 bar) for deep cleaning

Integrated cleaning brush to remove persistent residues

Wastewater collecting tank to manage used water

High-pressure piston pump (HP system) for powerful and reliable performance

Compressed air drying system for fast and efficient drying

Fully sealed structure to prevent water dispersion

PLC-controlled panel for cycle selection, with adjustable durations from 5 to 120 minutes

Efficiency, Sustainability, and Safety Advantages

WMG knife ring washer delivers greater efficiency, sustainability, and operating cost savings, improving knife ring performance and durability through thorough pre-sharpening cleaning.

Its PLC-controlled automation ensures consistent and repeatable results in every cycle, while minimizing maintenance effort and operator involvement.

Main benefits include:

-

Improved knife ring performance and durability through thorough pre-sharpening cleaning.

-

Consistent cleaning quality thanks to automated, PLC-controlled processes.

-

Reduced maintenance time and effort due to fully automated operation.

-

Optimized water usage through recovery and recycling systems.

-

Environmentally sustainable solution with minimized water waste.

-

Faster turnaround times thanks to integrated drying and efficient cycle options.

-

Enhanced safety and cleanliness in the workplace due to a sealed and well-contained design.

-

Quick installation and commissioning, reducing downtime before operation begins.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.