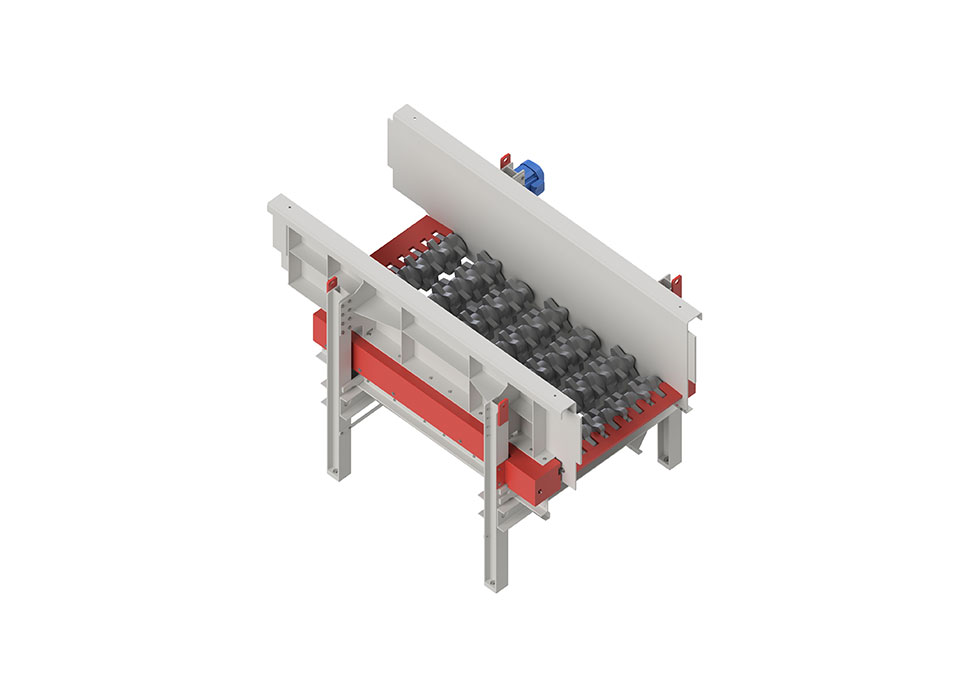

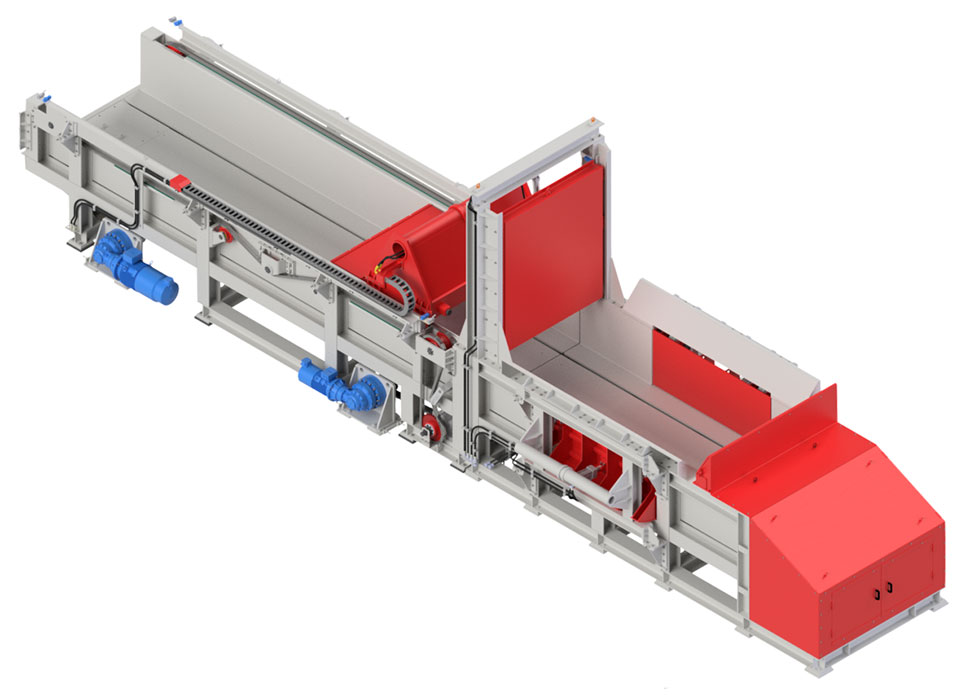

BFG – Batch Feeder

Standardized batch feeder design for SRG and SDG ensures flexibility and cost efficiency.

BFG batch feeder by Globus Srl is an advanced log feeding system designed for the SRG Ring Strander and SDG Disc Strander series.

It represents a single feeding platform for log cutting, ensuring precise alignment, consistent loading, and synchronized operation with the strander rotor.

Optimal log alignment

Semi-automatic loading via chain conveyor

Precise pushing into the cutting chamber with dual pushers

Compatibility with various log lengths

Enhanced handling capacity with optional single or double shaking system

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Applications and advantages of BFG Batch Feeder

BFG Batch Feeder by Globus Srl is an advanced log feeding system specifically engineered to supply the SRG Ring Strander and SDG Disc Strander series with a consistent, precisely aligned, and controlled flow of logs.

It serves as a single standardized feeding platform for log cutting operations, combining mechanical precision with automated synchronization to ensure stable material feeding and optimized process continuity.

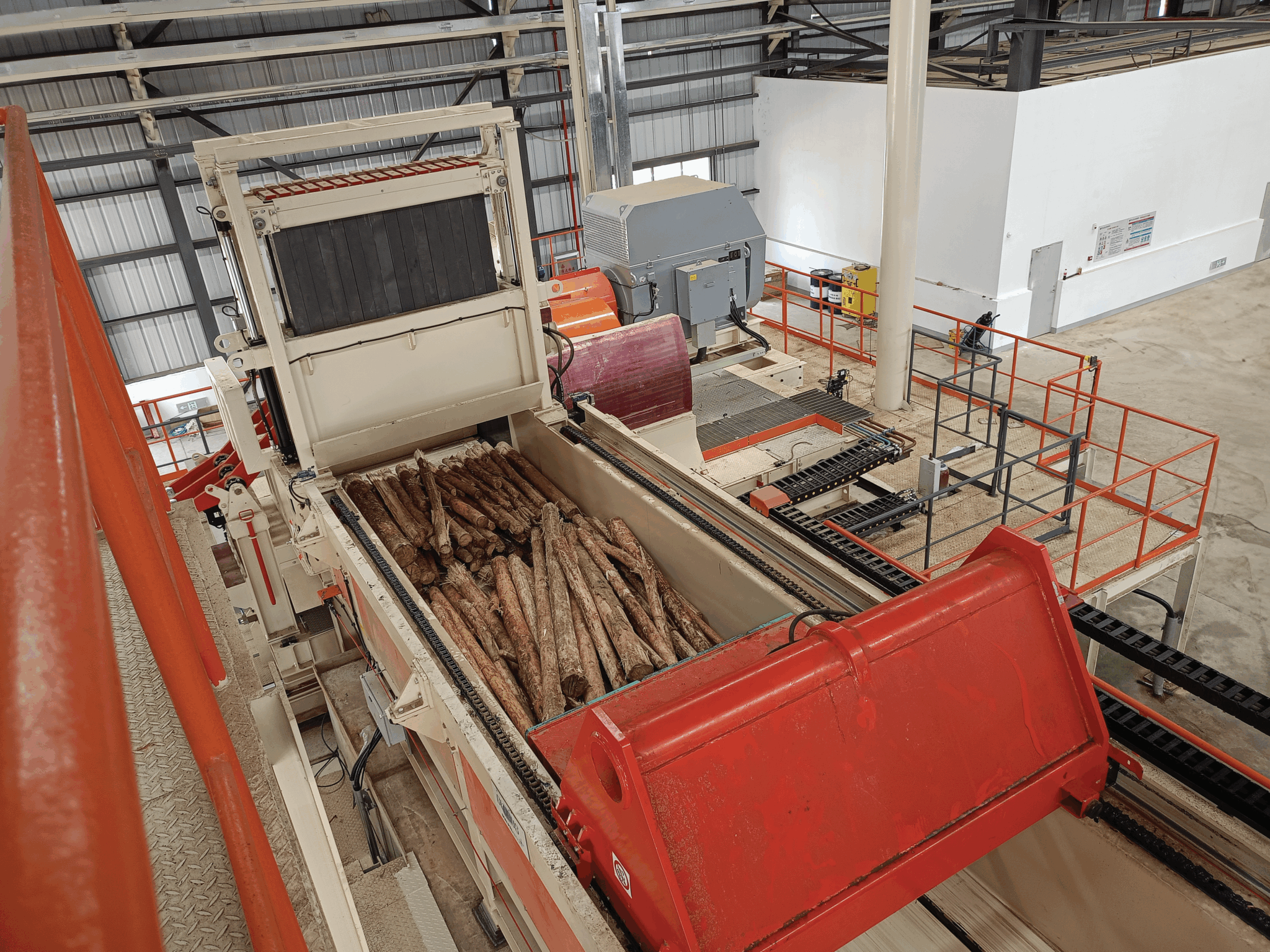

Thanks to its integrated control logic, BFG Batch Feeder guarantees perfect interaction with the strander rotor, reducing variations in feed rate and ensuring uniform strand production quality.

This advanced configuration simplifies line engineering, enhances operational safety, increases overall productivity, and significantly reduces mechanical stress on downstream cutting components, extending equipment life and improving production efficiency.

Universal feeding platform

Improved material flow control

Efficient transport and high storage capacity

Flexible configurations tailored to operational needs

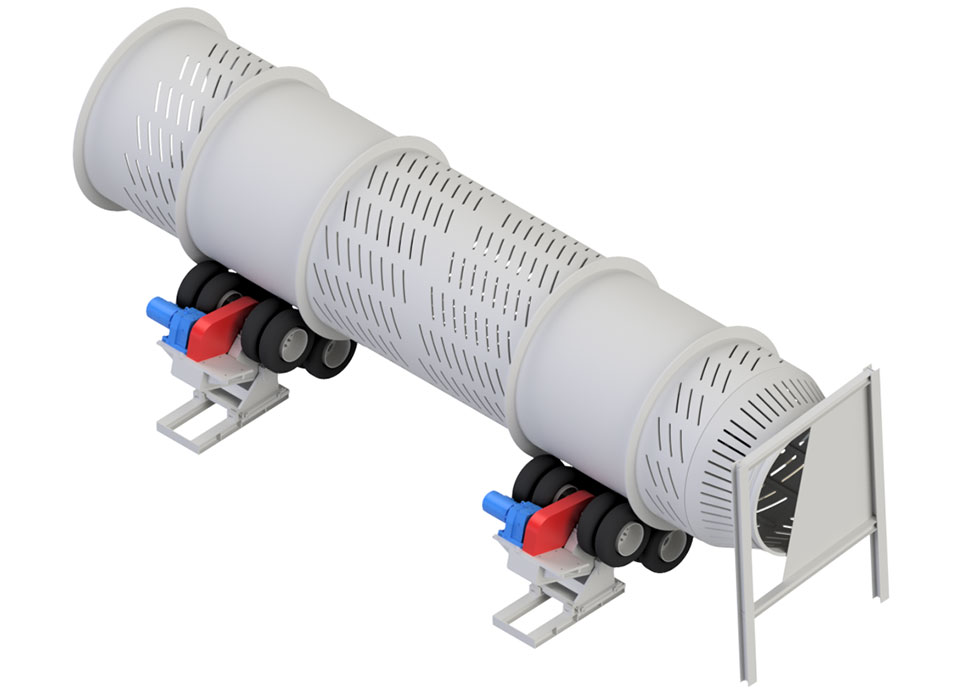

Universal feeding platform for both SRG (ring strander) and SDG (disc strander) lines

High operational flexibility with modular lengths to match log sizes

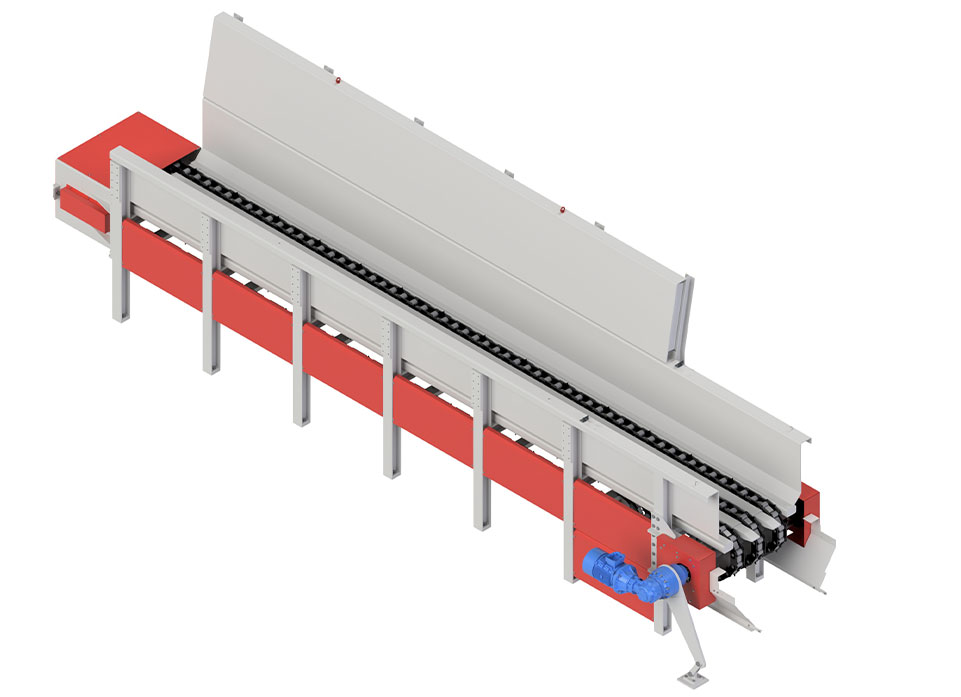

Semi-automatic loading via chain conveyor for improved safety and efficiency

Optimal log alignment through a two-pusher system ensures proper positioning in the cutting chamber

High-efficiency and precision feeding

Thanks to its hydraulic lifting forks, chain conveyors, and PLC-controlled automation, BFG Batch Feeder guarantees accurate batch loading cycles that optimize productivity and cutting efficiency.

Each cycle ensures stable log positioning and synchronized transfer, reducing idle time and maximizing throughput in both OSB and LSB production lines.

The standardized feeding system shared between the SRG and SDG models increases operational flexibility and simplifies spare-parts management, ensuring long-term cost efficiency and smoother maintenance scheduling.

Configurable design and versatility

BFG Batch Feeder is available in various lengths to accommodate different log sizes and can be configured with a single or double shaking system to improve material handling and log alignment.

Models include top loading (DS – double shaker) and side loading (SS – single shaker) options, both equipped with front and rear pushers for precise feeding and optimized log centering before cutting.

Its modular, customizable design allows flexible adaptation to plant layout and capacity, offering multiple configurations in width, length, and load performance.

This versatility ensures seamless integration with new installations or retrofit upgrades on existing stranding lines.

Integration and operational advantages

BFG Batch Feeder forms an essential link in complete wood preparation and stranding lines, feeding the SRG Ring Strander or SDG Disc Strander with perfectly positioned logs.

Its automation ensures consistent cutting rhythm, improved strand quality, and reduced operator involvement.

Thanks to these advanced features, BFG delivers high performance, long service life, and minimal downtime, optimizing wood handling efficiency and ensuring continuous, stable production in the most demanding industrial environments.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.