ASR – Sharpening Room

An innovative fully automated knife sharpening room system

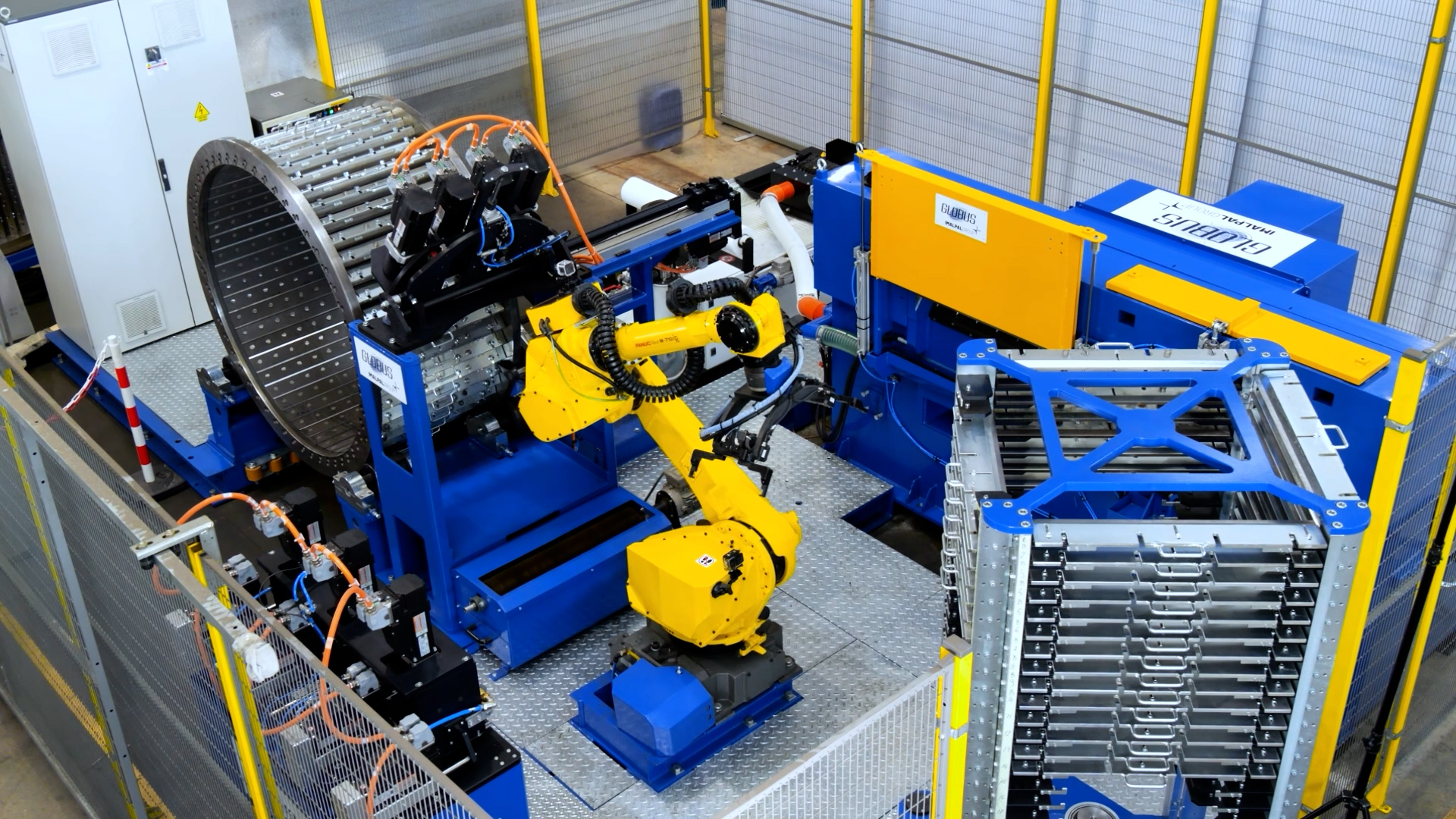

ASR automatic sharpening room utilizes a 6-axis robotic system capable of managing multiple sharpening programs and processing variations without operator intervention, ensuring precision, safety, and consistent knife ring performance.

Full Automation and precision

Improved safety and reduced labor

Optimized maintenance

Sustainability and cost reduction

Wood based panels

PB/SPB OSB/LSB/FOSB

Applications and advantages of ASR Automatic Sharpening Room

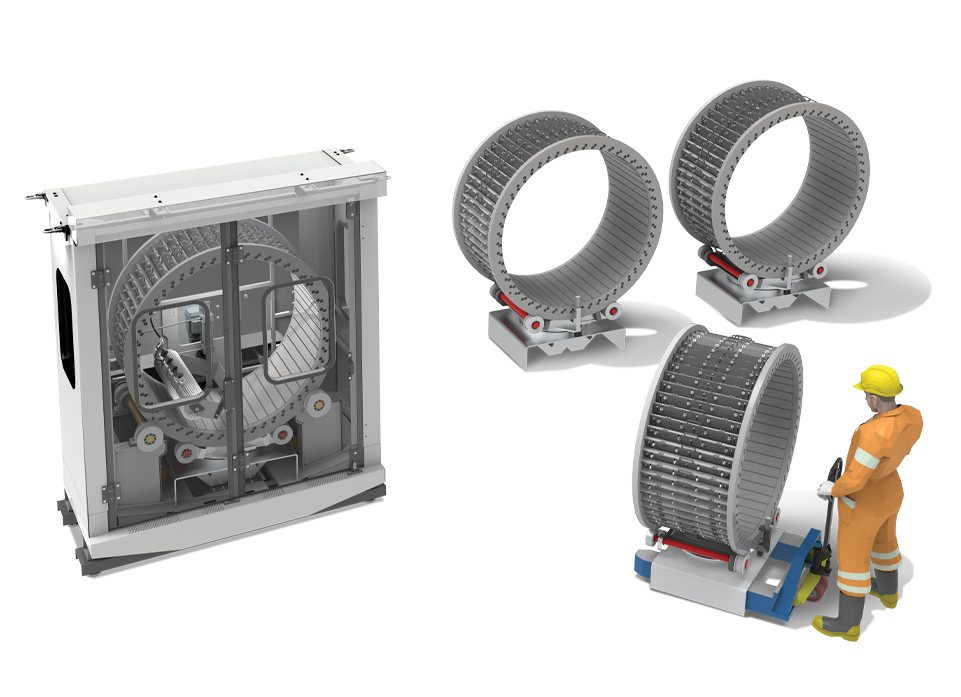

ASR automatic sharpening room by Globus Srl is a fully automated system designed for knife ring maintenance in flakers.

This advanced solution allows complete control of the sharpening process, ensuring consistent cutting quality, safety, and precision while minimizing human intervention.

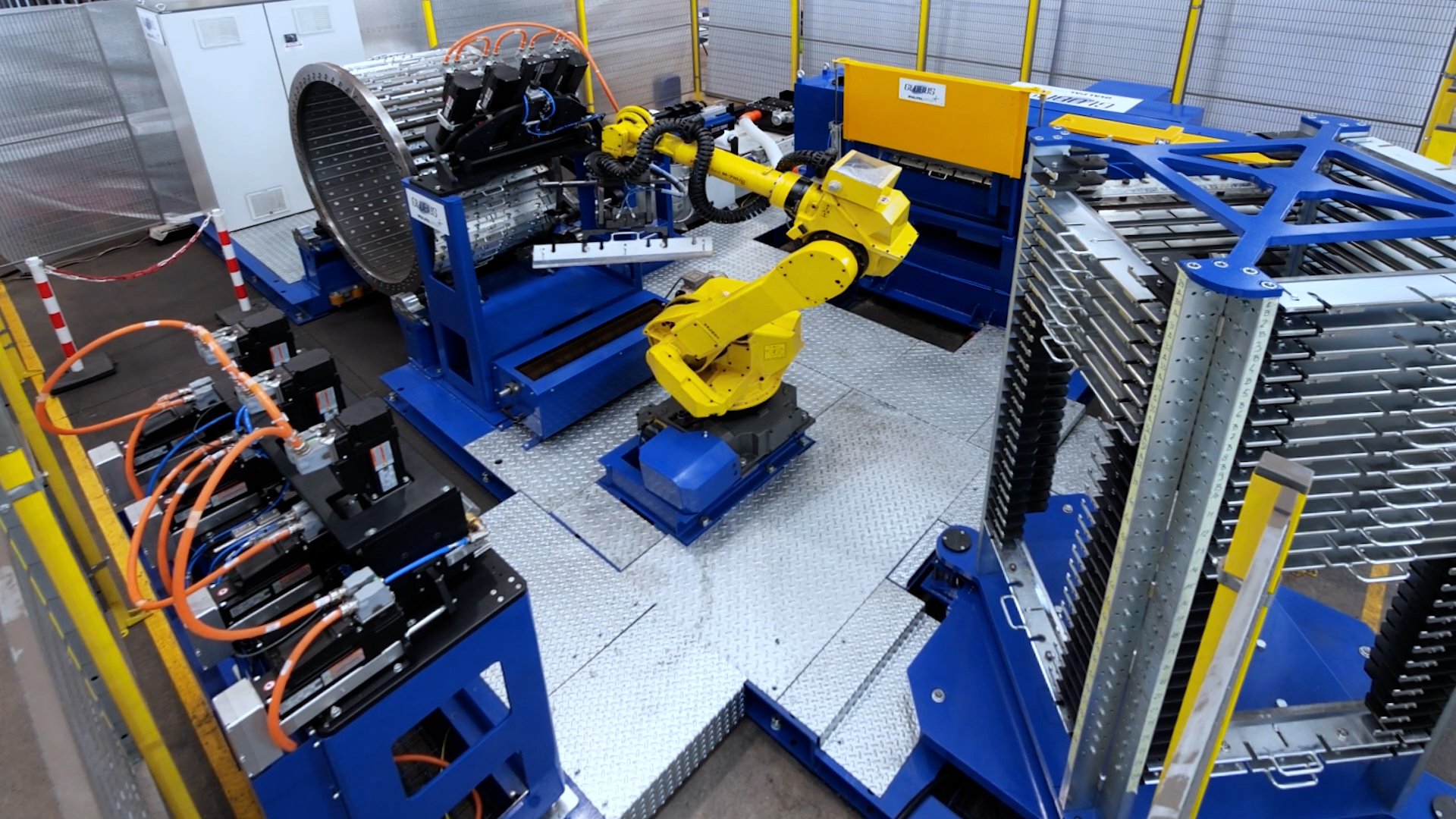

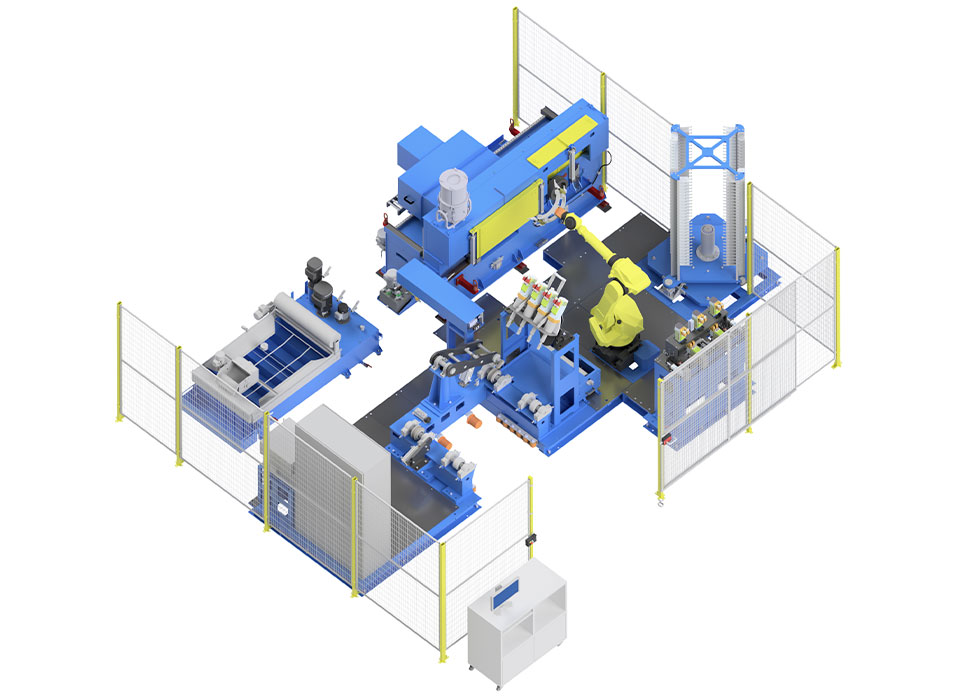

Equipped with a 6-axis robotic system, ASR sharpening room handles multiple sharpening programs and process variations without operator assistance, guaranteeing repeatable accuracy and reliable knife performance.

Its automation reduces downtime, improves safety, and optimizes the entire knife management workflow inside wood-based panel plants.

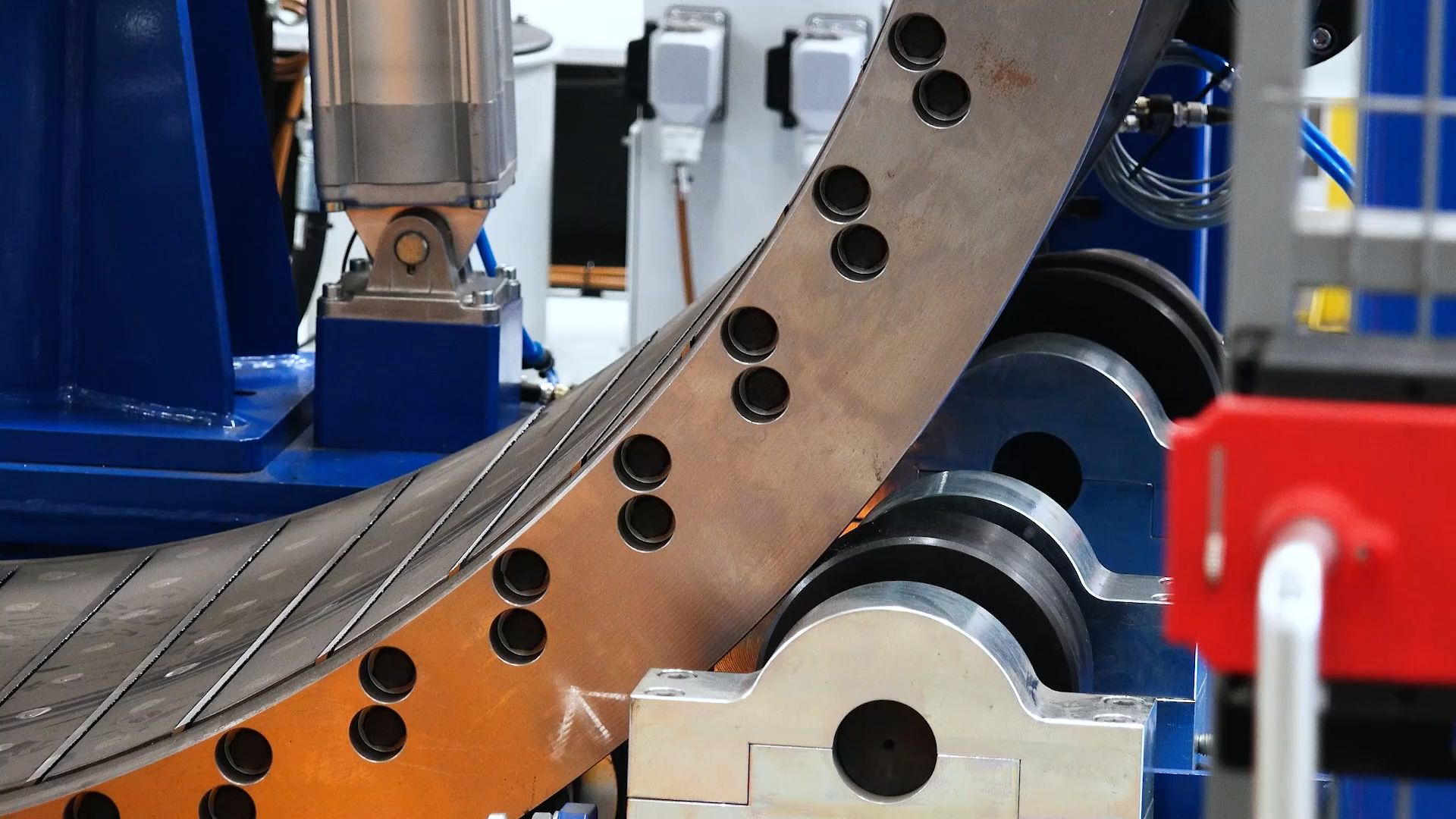

Optical scanning ensures precise material removal

The fully enclosed chamber enhances workplace safety

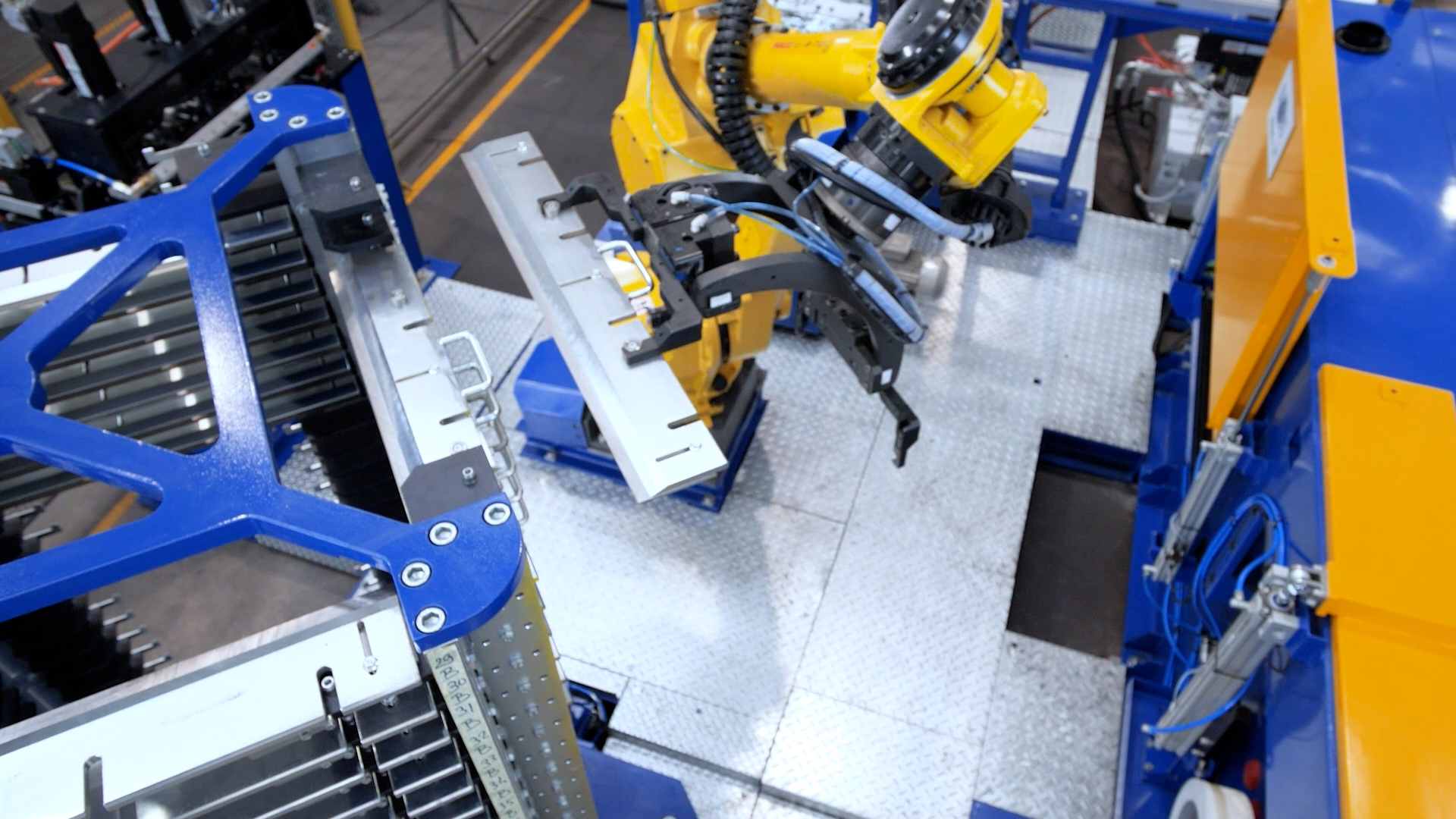

Operators handle knives 90% less

Technical features

High-pressure system with water jets up to 160 bar, ensuring deep and effective cleaning

Integrated cleaning brush, for removing persistent residues

Wastewater collecting tank, ensuring a clean and organized process

Wastewater recovery system, allowing for optimized water consumption and environmental sustainability

High-pressure piston pump (HP system), providing reliable and powerful pumping performance

Compressed air drying system, eliminating water residues and speeding up processing times

Fully sealed structure, preventing water dispersion for a cleaner and safer work environment

Water recovery option, optimizing water usage and reducing waste

Optional water heating system, improving cleaning efficiency, especially in demanding applications

ASR Efficiency, Precision, Safety, and Sustainability

ASR (Automatic Sharpening Room) offers significant advantages in efficiency, precision, safety, and sustainability, redefining maintenance standards for knife ring flakers and centrifugal mills.

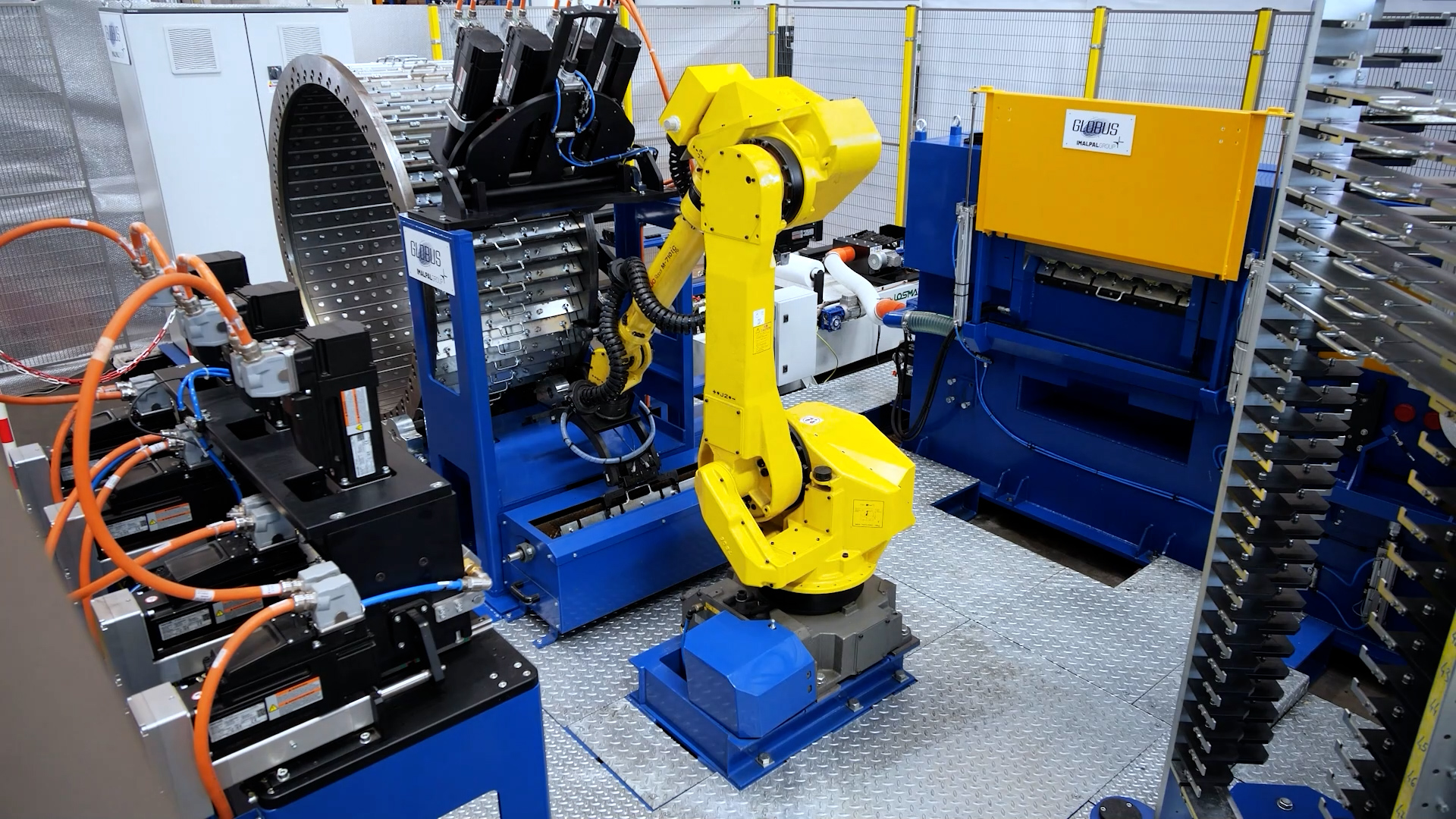

Increased efficiency – ASR can sharpen 54 knives in just 50 minutes and manage up to 8 mills simultaneously, allowing the sharpening of 16 knife rings per day while reducing overall knife usage by 50% annually.

This capability translates into higher productivity, lower tool costs, and improved line availability.

Full automation and precision – The fully automated 6-axis robotic system ensures precise sharpening with an optical scanning system that identifies the exact material to be removed.

An integrated automated knife alignment feature detects damaged screws or irregularities, maintaining constant accuracy and surface finish quality.

Improved safety and reduced labor – In terms of operator safety, ASR minimizes manual handling and reduces knife contact time by 90%, drastically lowering the risk of workplace injuries.

Its fully enclosed chamber provides a controlled environment that enhances both operator protection and sharpening efficiency.

Optimized maintenance and monitoring – ASR continuously monitors knife wear and transmits real-time data to the plant control system, optimizing flaker performance and predictive maintenance scheduling.

Sustainability and cost reduction – The integrated water recovery system reduces waste and consumption, supporting environmentally responsible operation.

Automation minimizes downtime and material loss, making ASR both a cost-effective and eco-friendly solution.

Integration and Industrial Benefits

Globus ASR automatic sharpening room integrates seamlessly with other Globus equipment, such as the SRC Knife Ring Flaker, creating a complete and automated knife management ecosystem for the wood-based panel industry.

Developed and manufactured in Italy, the ASR automatic sharpening room combines innovation, reliability, and sustainability, ensuring superior knife ring performance and long-term operational excellence.

ASR has revolutionized the concept of knife sharpening, turning it into a fully automatic process that is continuously monitored at every stage.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.