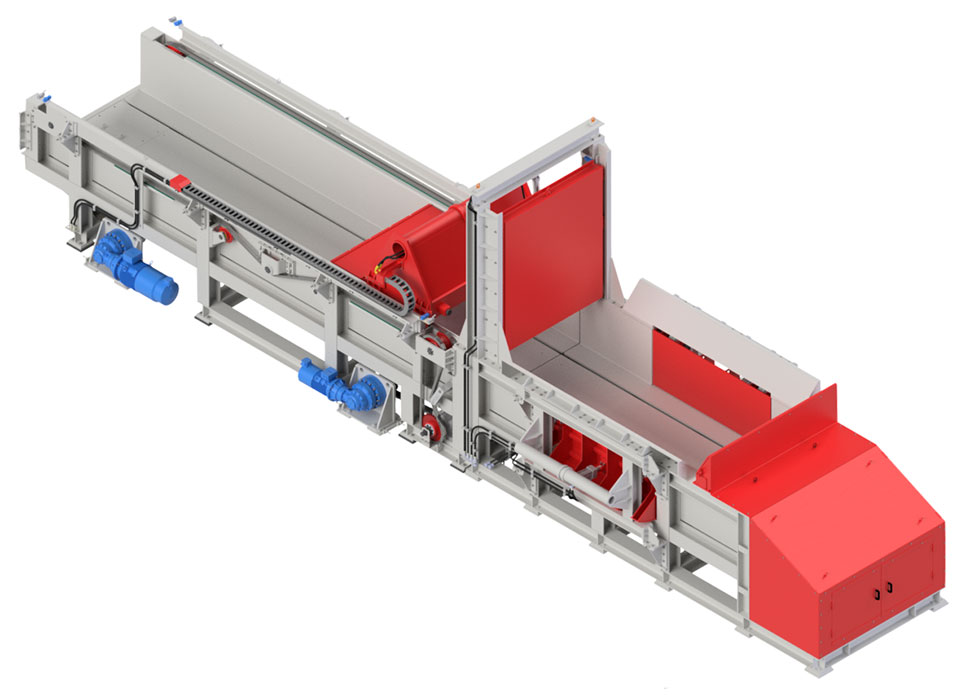

NT MD- Belt Conveyor with Metal Detector

The robust structure ensures a constant and controlled feeding process also thanks to the integrated metal detector option

NT MD are mainly used before the chipper or for direct loading of heavy logs and are available in three configurations, depending on the level of robustness required.

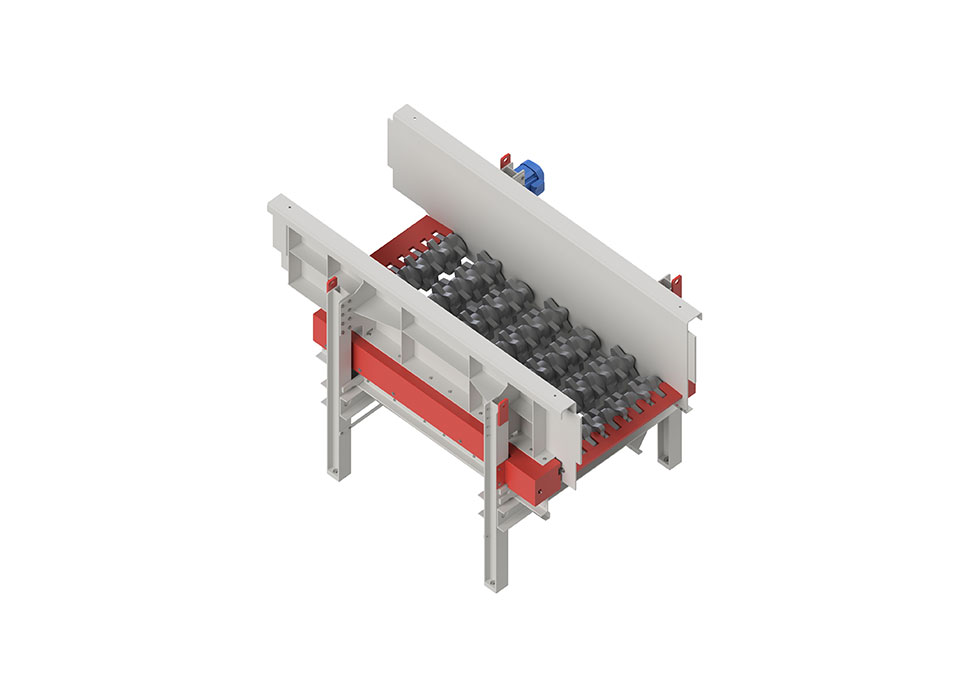

Integrated scrapers for automatic chain rail cleaning

Adjustable speed via inverter

Roller system to reduce wear and extend operational life

Quick-assembly structure

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets and black pellets, green fuels and biomass

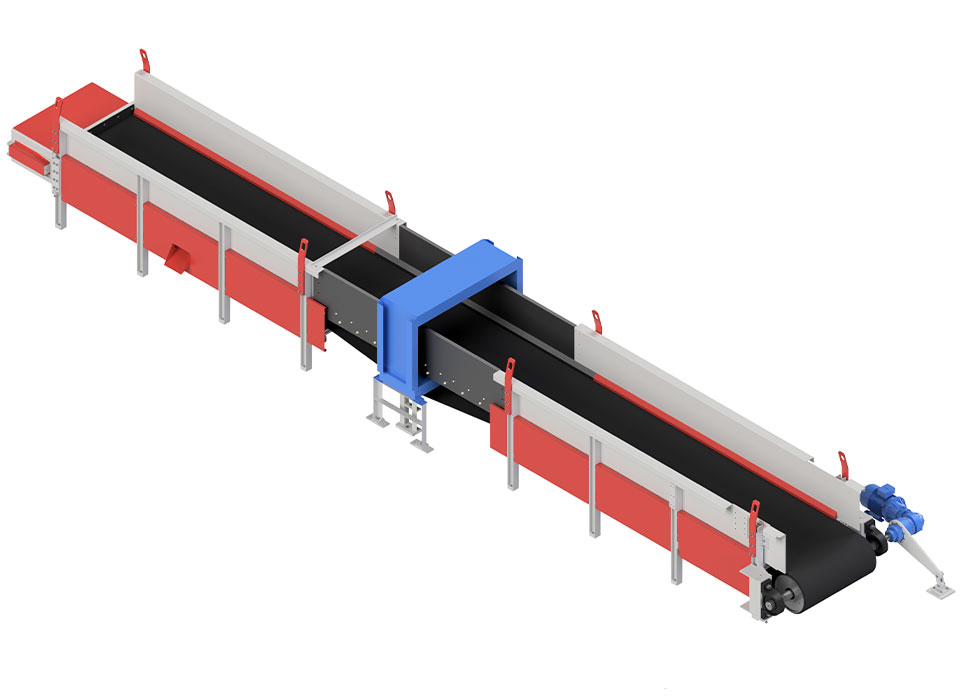

Efficient Belt Conveyor designed to meet different material handling requirements

NT MD is available in various lengths and widths, making it a versatile solution for different chipping lines.

Key features include:

- Tailored solutions – technologies to match different speed and length requirements

- Reinforced structure – built to withstand impacts, wear, and heavy loads

- Constant material flow – speed regulation ensures uniform and uninterrupted feeding

- Metal detector integration – detects and removes metal contaminants, protecting downstream machinery

Metal detector integration

Tailored solutions to match different speed and length

Constant material flow

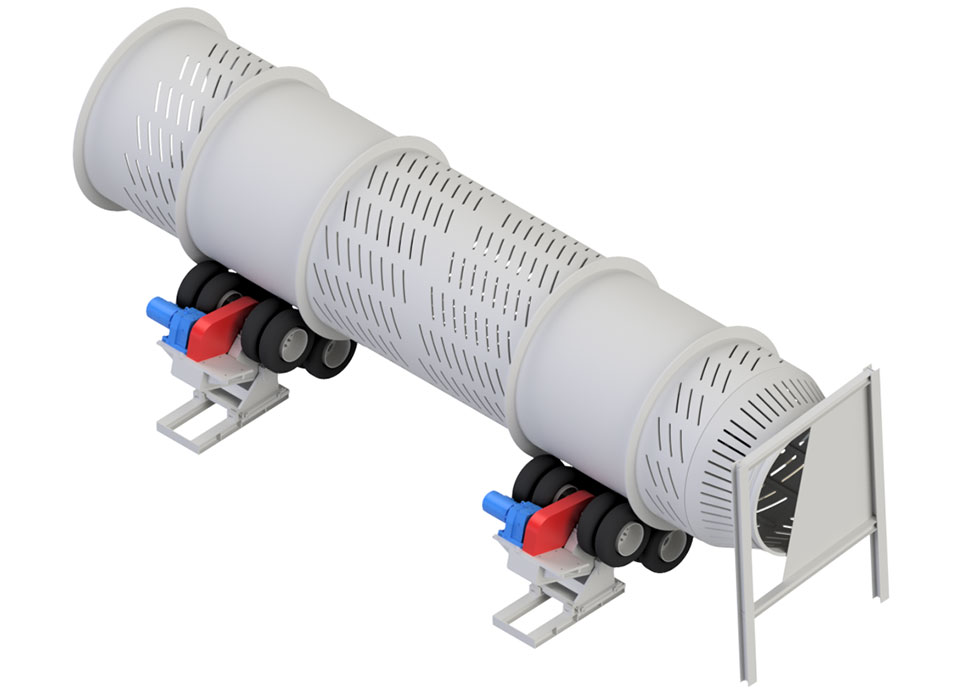

Ideal for low speeds and short lengths

Length: from 8 to 20 meters, modular for extended configurations

Belt width: up to 1,800 mm, adaptable to the type of material being processed

Metal detector integration – detects and removes metal contaminants, protecting downstream machinery

Reinforced impact zone, with specific coatings to protect the belt

Adjustable speed control via inverter, to optimize material flow

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.