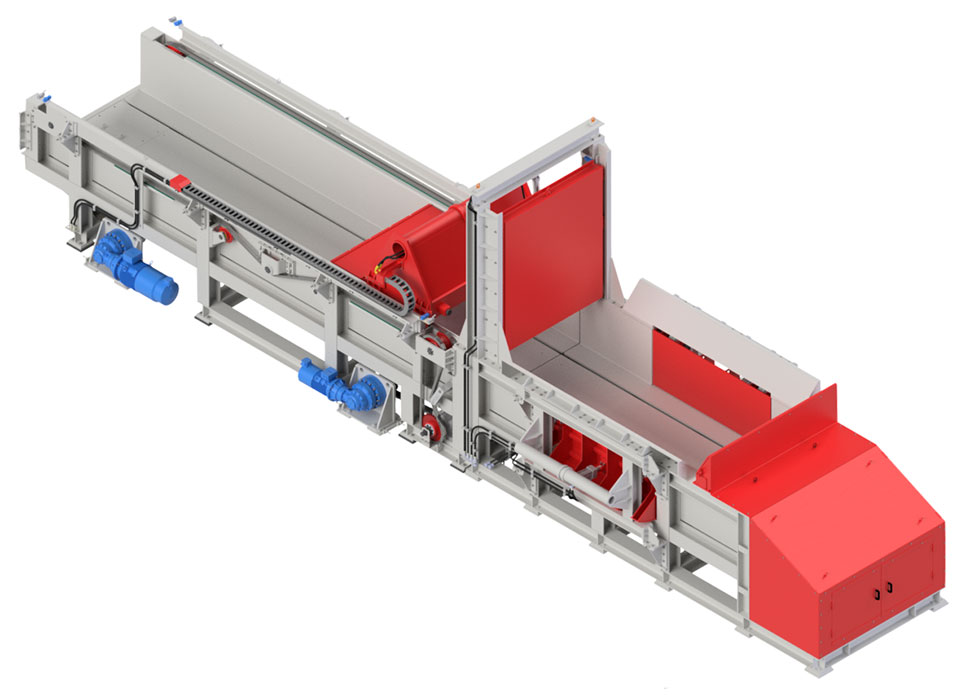

AVG – Vibrating Feeder

Reliable vibrating channel for wood material handling and panel line efficiency

AVG vibrating channel by Globus Srl ensures smooth and continuous wood material feeding, improving flow consistency and enhancing the efficiency of downstream operations in wood-based panel production lines.

Efficient material transport

Adjustable settings

Regulated suspension system

Wood based panels

MDF/HDF PB/SPB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets, green fuels and biomass, lime

Wood Recycling and Waste Treatment

Waste

Applications and advantages of AVG Vibrating Channel

AVG vibrating channel by Globus Srl is an industrial feeding system designed for the transport and distribution of wood chips, flakes, and sawdust in OSB, MDF, particleboard, and biomass production lines.

This robust and reliable vibrating channel ensures steady material flow, homogeneous feeding, and uniform distribution to downstream machines such as drum chippers, knife ring flakers, or refiners.

Its compact structure and advanced vibration technology guarantee smooth operation, minimal maintenance, and consistent material alignment even under heavy loads or variable moisture content.

The system’s mechanical design is optimized for continuous operation, ensuring excellent durability and energy efficiency.

Customizable angle settings

Regulated suspension system

Efficient material transport

Advanced solutions for material handling

Consistent material flow: vibrating feeders provide a steady, continuous flow of materials

Adjustable feeding rates: feeding rate can be easily adjusted to match specific requirements

Improved distribution: ensure optimal distribution of materials

Durability and reliability: built with high-quality materials and strong components, vibrating feeders are designed to withstand heavy use in demanding environments

Energy efficient: vibrating feeders are energy-efficient, using low power to move materials, which can lead to cost savings over time

High-Efficiency Feeding and Material Control

AVG vibrating channel uses a leaf-spring suspension system and an adjustable eccentric drive to deliver high-frequency vibration for optimal material flow.

This configuration allows precise control over feeding rate, prevents clogging, and ensures accurate alignment of wood particles.

Main benefits include:

-

Uniform material feeding across the full width of the downstream machine.

-

Reduced material build-up and clogging thanks to high-frequency vibration.

-

Durable construction for 24/7 operation in demanding industrial environments.

-

Low maintenance design with easily accessible components.

-

Energy-efficient system with minimal power consumption.

-

Compact installation footprint, ideal for retrofitting existing lines.

AVG vibrating channel can be customized in length, width, and vibration frequency to match specific plant requirements, ensuring perfect integration with other Globus systems such as the MTG Drum Chipper or SRC Knife Ring Flaker.

Integration and Industrial Benefits

In wood-based panel plants, the vibrating channel serves as a crucial link between size-reduction and refining stages, ensuring continuous, balanced material supply to maximize line efficiency.

Its design reduces downtime, improves overall plant productivity, and minimizes manual intervention.

Built in Italy by Globus Srl, AVG vibrating channel represents advanced feeding technology for modern panel production, combining reliability, precision, and sustainability.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.