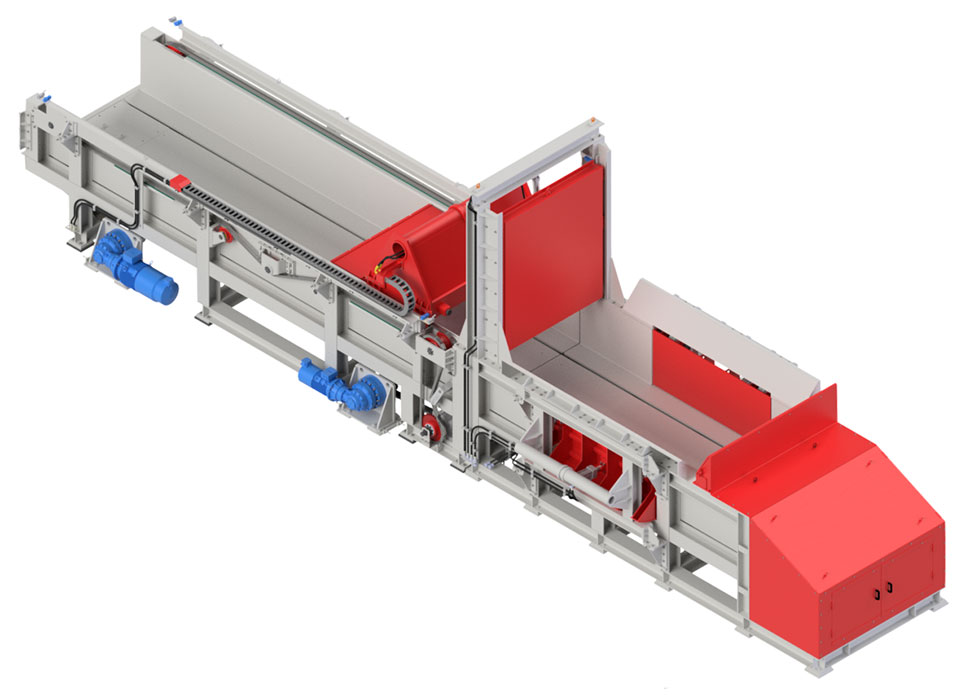

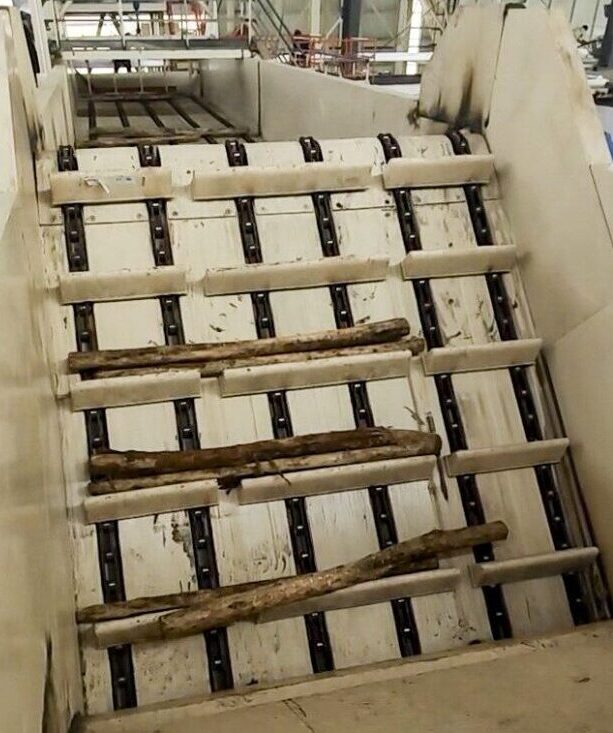

LDG – Log Dosing System

Maximize process efficiency and efficient log flow control

LDG is a dosing systems designed to dose and separate logs ensuring controlled and continuous feeding to the next processing stages.

Optimized productivity

Precise and consistent dosing

Uniform material flow

Maximum adaptability

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets, green fuels and biomass

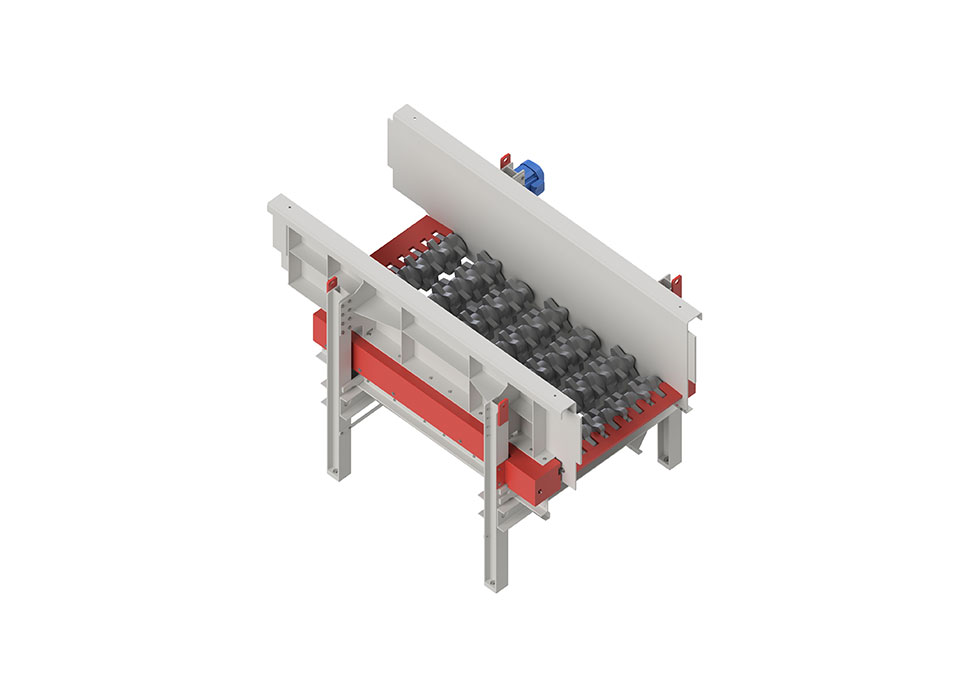

Precise and continuous log feeding system

LDG dosing systems are designed to dose and separate logs, ensuring controlled and continuous feeding to the next processing stages. These systems are particularly suitable for:

-

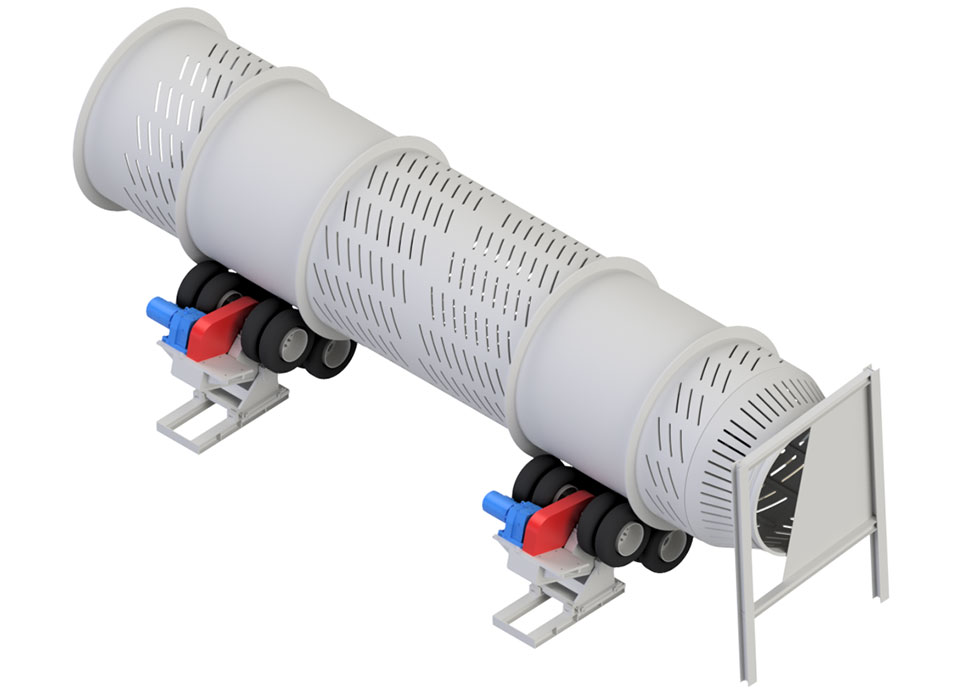

Chipping Lines: regulate log flow towards drum debarkers or other pretreatment systems, optimizing process efficiency.

-

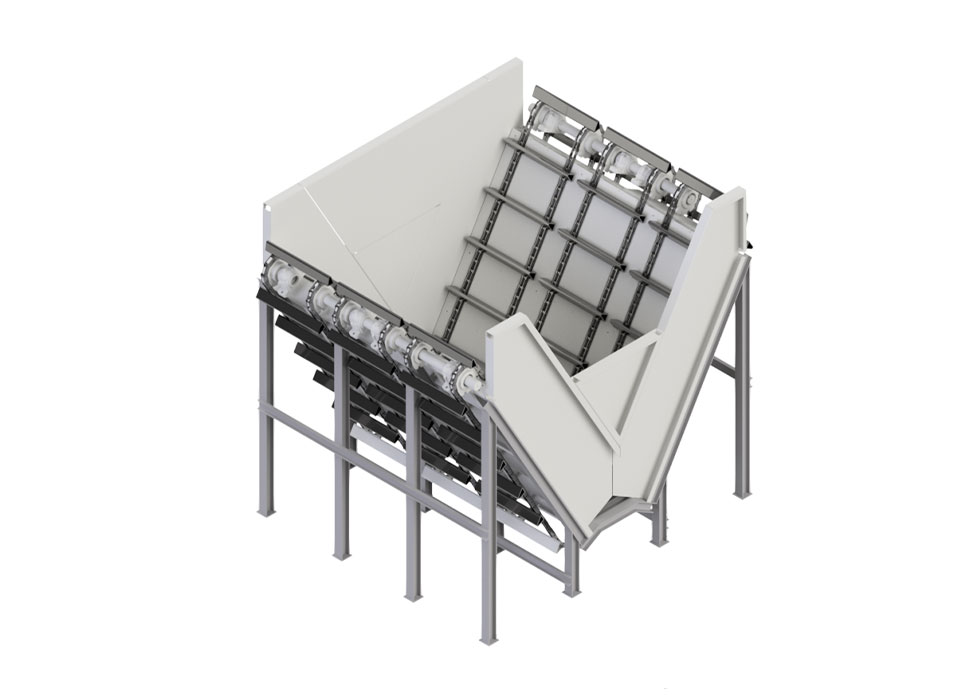

OSB Production Lines: ensure a steady material flow to direct grinders, such as Disc Stranders or Ring Stranders, preventing overloads and ensuring consistent feeding.

Available Configurations:

-

Twin LDG Version: designed for high-capacity plants, this configuration enables material distribution to two processing lines using a single dosing system. It’s ideal for installations downstream of a debarker, efficiently feeding two Strander lines in parallel.

-

Single LDG Version with Metal Detector: when combined with a detection system, this version can identify and automatically reject metal-contaminated logs, preventing machine damage and improving raw material quality.

Thanks to its modular design and heavy-duty construction, LDG dosing systems ensure high reliability, precision, and maximum operational efficiency even in demanding industrial environments.

Precise and consistent dosing

Compatible with Metal Detector

Modular and Heavy-Duty Construction

Maximum adaptability to meet evolving production needs

Length: up to 6 meters, with modular configurations

Width: from 1,500 mm to 6000 mm, adaptable to different log sizes

Number of chains: from 2 to 6, with customizable pitch to suit processing needs

Adjustable speed: from 5 to 30 m/min, with inverter control for optimized dosing

Compatible with Metal Detector, for automated removal of contaminated logs

Designed for installation downstream of a debarker, allowing feeding of two processing lines with the Twin LDG version

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.