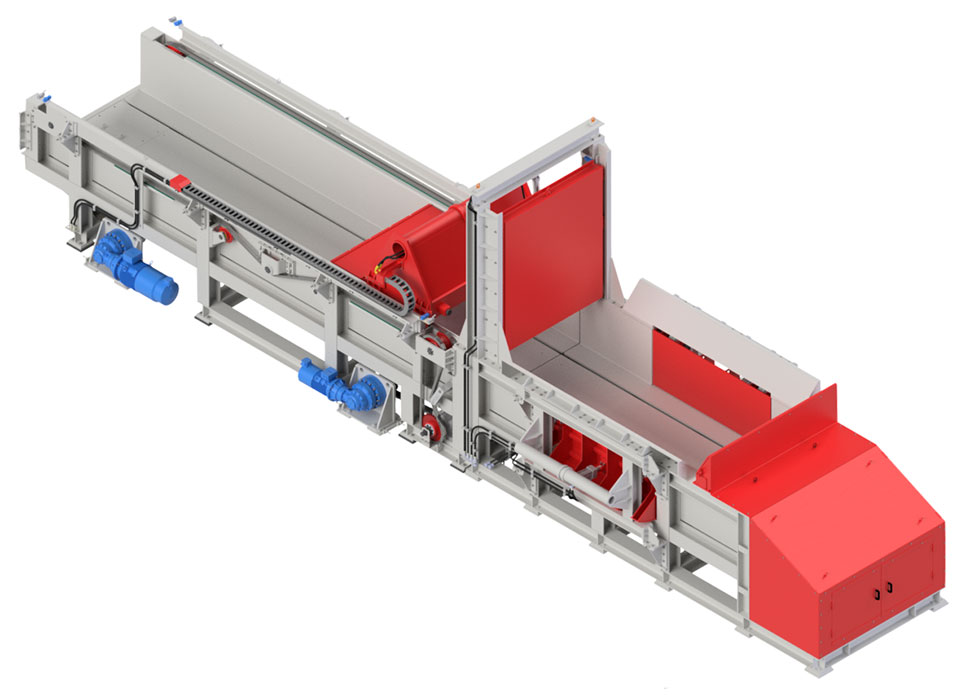

LCG – Longitudinal Chain Conveyors

LCG Longitudinal Chain Conveyor combines high storage capacity and low maintenance requirements, ensuring efficient and reliable wood log handling in continuous operation.

LCG is a robust and efficient longitudinal chain conveyor designed for the continuous feeding of wood logs.

Integrated scrapers for automatic chain rail cleaning

Adjustable speed via inverter

Roller system to reduce wear and extend operational life

Quick-assembly structure

Wood based panels

MDF/HDF PB/SPB OSB/LSB/FOSB

Pressed wood packaging

Pallet blocks and pressed pallets

Pellets & Energy

Wood pellets, green fuels and biomass

Applications and advantages of LCG Longitudinal Chain Conveyor

LCG Longitudinal Chain Conveyor by Globus Srl is a heavy-duty log feeding system engineered for continuous and controlled wood material transport in wood-based panel and biomass production lines.

This robust longitudinal chain conveyor ensures smooth, efficient material flow between debarking, chipping, and stranding machines, maintaining a constant feeding rate and minimizing mechanical stress on downstream equipment.

Main benefits

- Continuous and uniform log feeding

- Modular and extendable structure

- Easy installation with no welding required on site

- Low energy consumption and minimal maintenance

- High storage capacity for buffer management

- Proven reliability in demanding industrial environments

Customizable dimensions

Flexible loading options

Continuous and precise log feeding

Modular design to meet evolving production needs

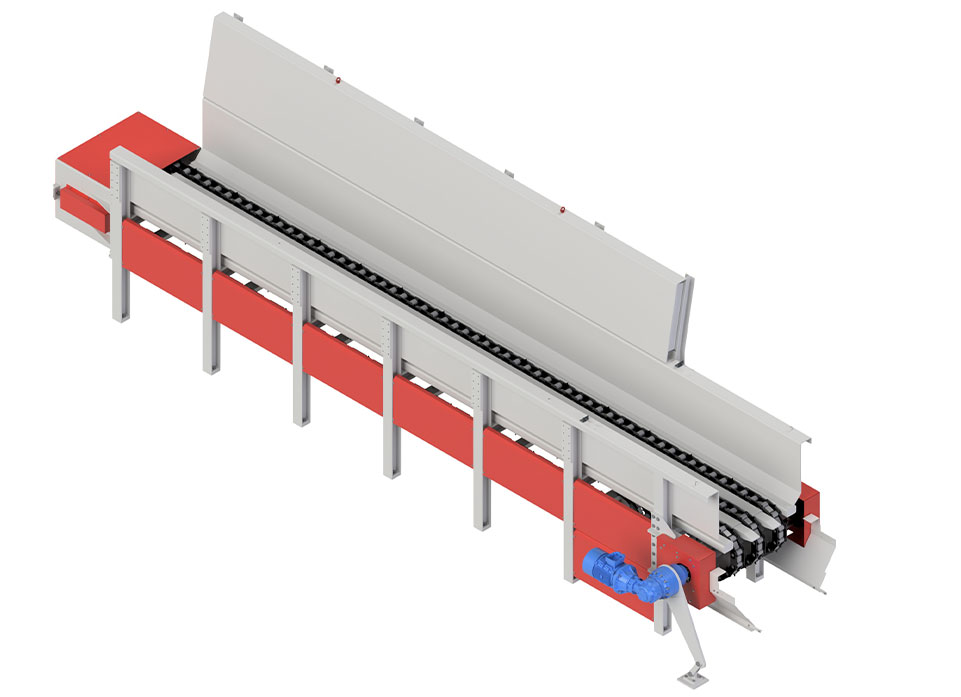

Length: from 8 to 24 meters, modular for extended configurations

Width: from 800 mm to 1,800 mm, depending on the chipping line

Customizable sidewalls for optimized material containment

Compatible with direct crane loading or automatic dosing systems (e.g., TCD)

Heavy-duty frame designed for impact resistance

Torque-based adaptive speed control via inverter for smooth operation

High-capacity, durable, and modular design

Built for durability, LCG Longitudinal Chain Conveyor features a reinforced steel structure that absorbs impact from incoming logs, ensuring reliable operation even in the most demanding industrial environments.

Its modular construction allows easy adaptation to specific plant layouts and future production expansions.

Available in various lengths, widths, and chain configurations, LCG can be customized to suit the needs of any chipping or stranding line, offering maximum flexibility and operational efficiency.

Thanks to its sturdy build and low-maintenance design, LCG conveyor delivers outstanding performance and a long service life, making it an ideal choice for heavy-duty log handling applications.

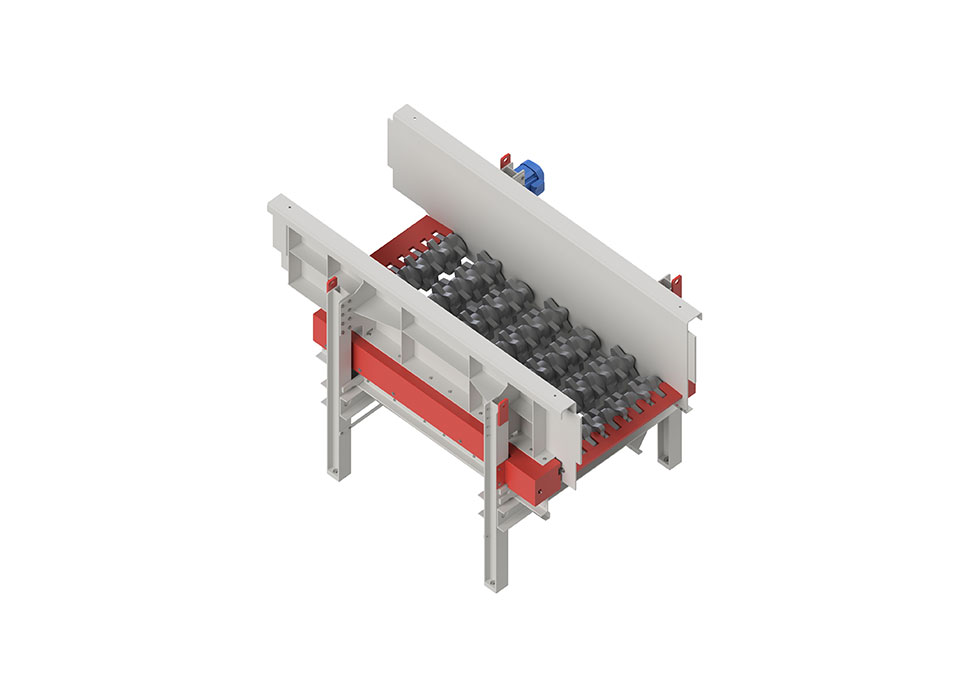

Integrated automation and technical features

LCG Longitudinal Chain Conveyor integrates advanced automation and mechanical solutions that improve performance, reliability, and ease of maintenance.

Key features include:

- Integrated scrapers for automatic chain rail cleaning

- Adjustable speed via inverter for optimized process control

- Roller system to minimize friction and extend component life

- Quick-assembly frame, eliminating on-site welding for faster installation and maintenance

These features ensure stable log movement, reduced wear, and consistent operation even under continuous 24/7 workloads.

Its high storage capacity and energy-efficient operation make it an essential element in modern wood preparation systems.

Integration and system compatibility

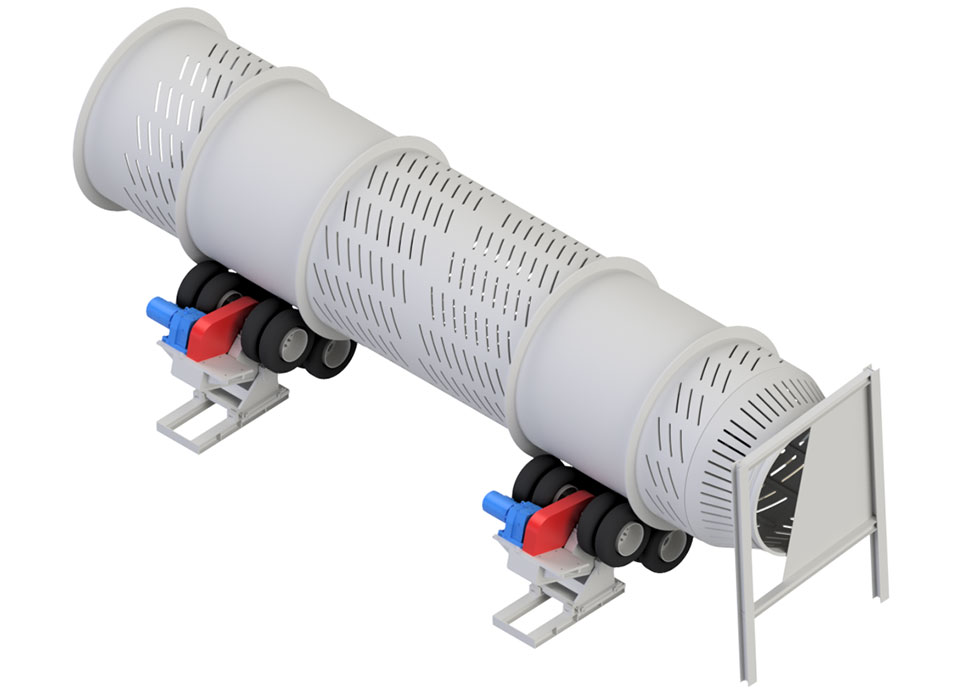

LCG Longitudinal Chain Conveyor seamlessly integrates with other Globus equipment, forming a key component in complete wood-processing lines.

It is typically installed between the DDG Drum Debarker and MTG Drum Chipper, ensuring a consistent and even flow of cleaned logs for optimal chip production.

More info

Would you like to request specific information about a product? Fill out the form below, and we will get back to you.